Multi-ring Plasma Pyrolysis Chamber

a plasma pyrolysis chamber and multi-ring technology, applied in the direction of combustible gas production, energy input, chemistry apparatus and processes, etc., can solve the problem of additional operational expense of oxygen use, and achieve the effect of reducing pre-heated fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

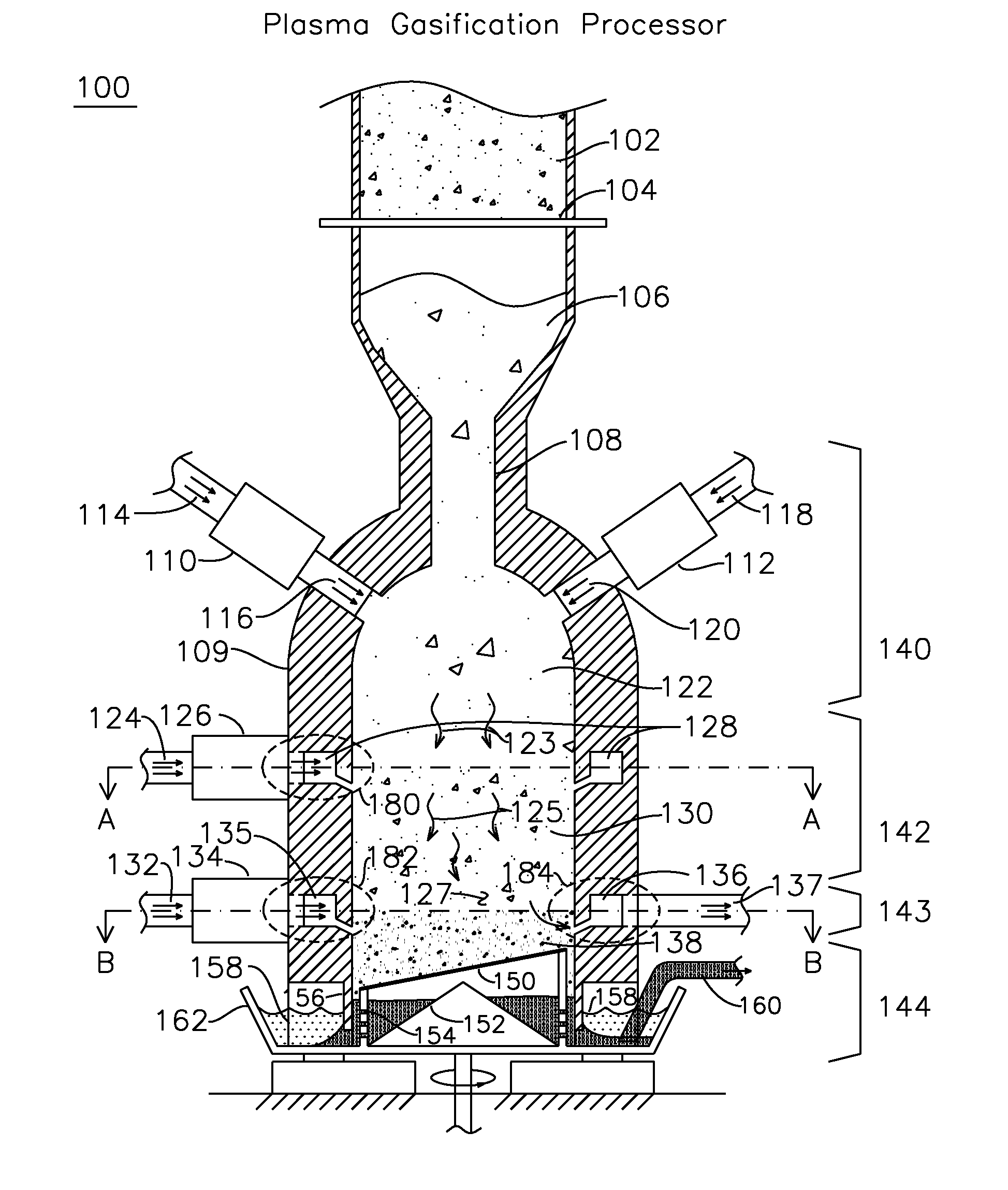

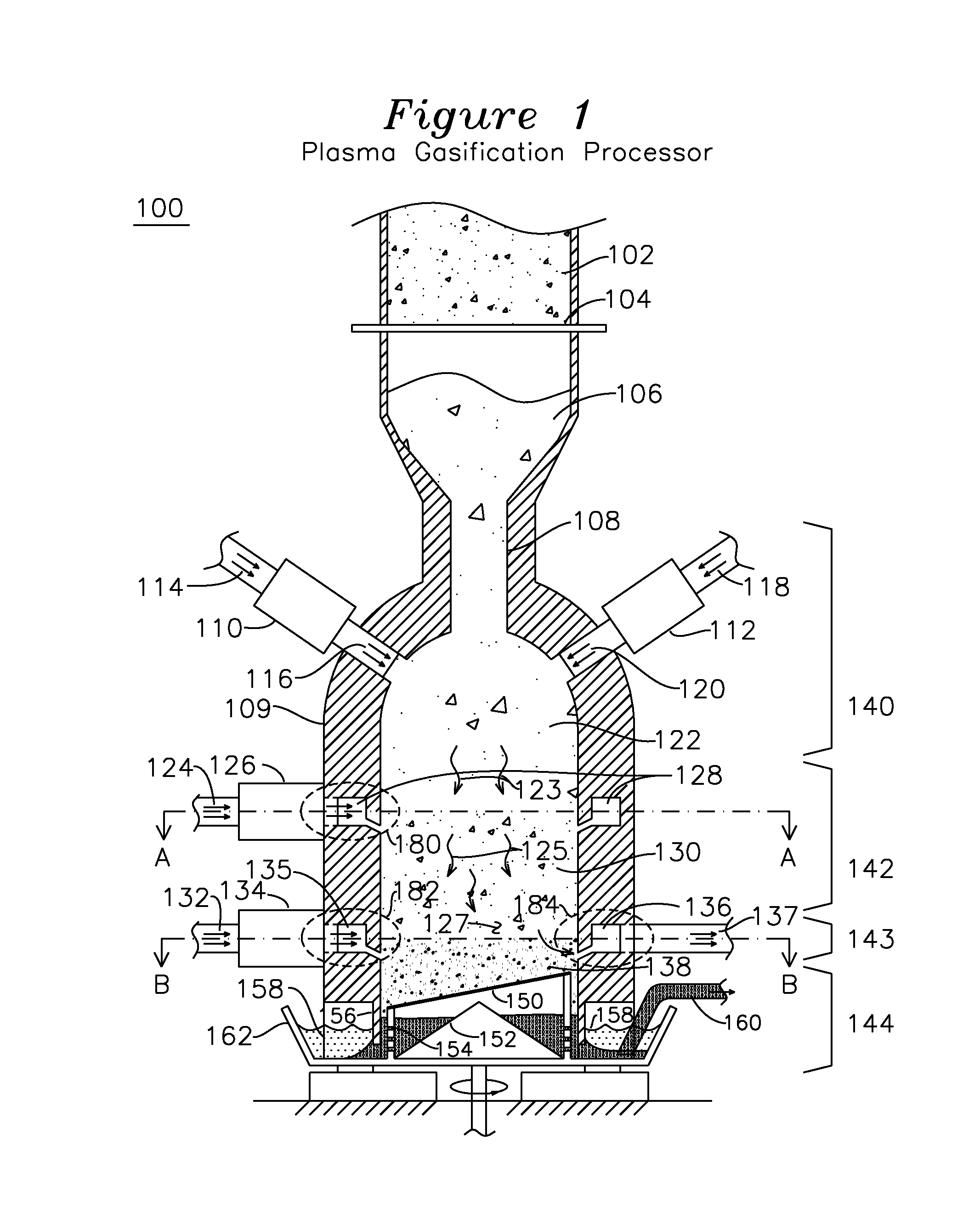

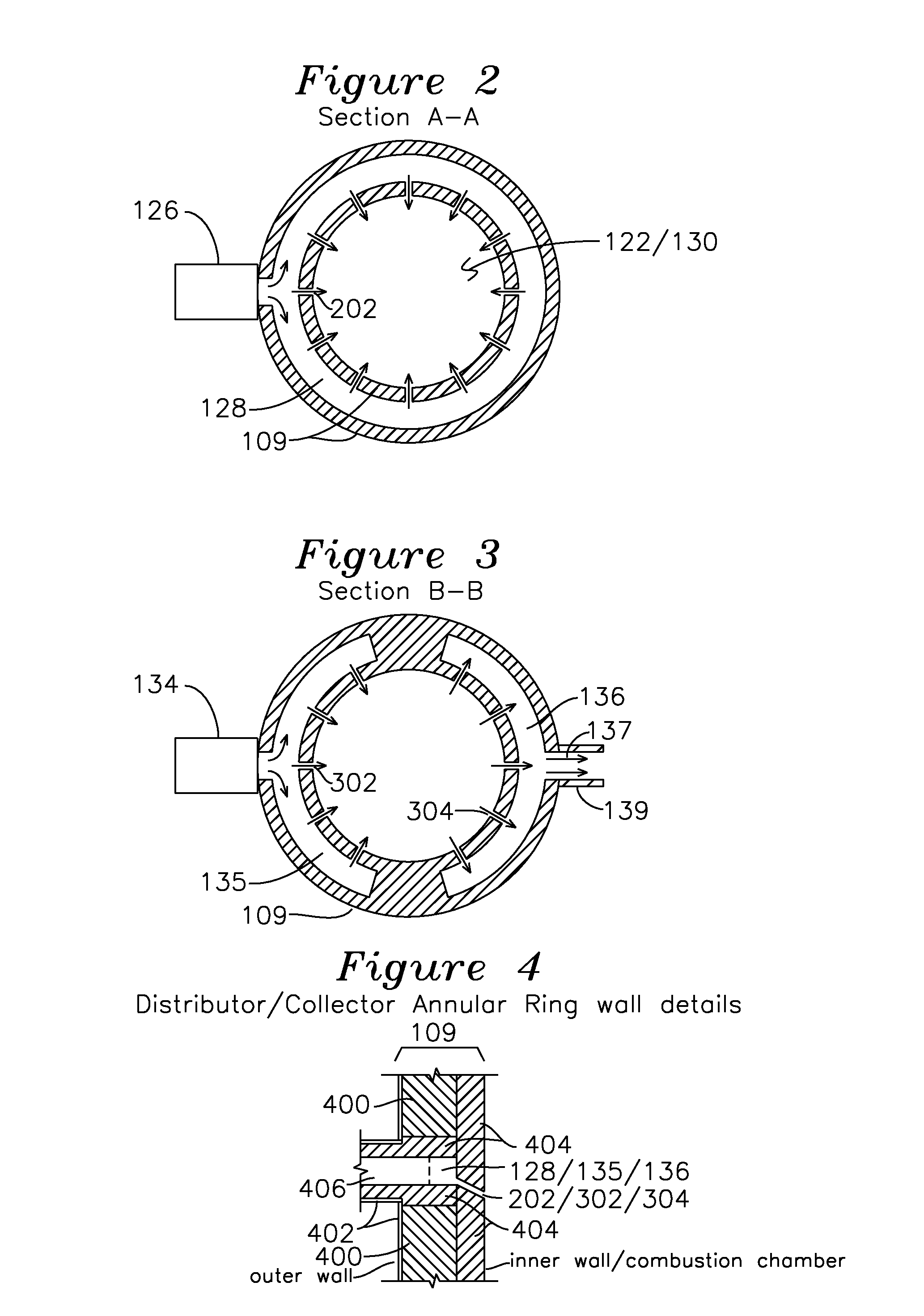

[0022]The present invention describes an apparatus and method for pyrolytic waste recovery which can extract energy in the form of combustible gases from a wide variety of heterogeneous organic materials including municipal refuse, biomass, agriculture wastes, wood and forest product processing wastes, hazardous wastes, petroleum coke, coal or oil shale, individually or as mixtures. Depending on the nature of the input fuel, the resultant combustible gas is suitable use as a fuel for electric power generation, for conversion to synthetic hydrocarbons, hydrogen, or other valuable chemicals. In one embodiment of the invention, the combustible gas includes H2 and CO and a steam plasma is injected in the oxidation and reduction zone which generates these gasses, the steam plasma containing sufficient energy to compensate for the endothermic heat required to generate these combustible gasses. In another embodiment of the invention, the fuel is wood chips or other biomass fuel. The instan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| arc length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com