Alpha-Amylases

a technology of alpha-amylase and beta-amylase, applied in the field of alpha-amylase variants, can solve the problem of disadvantage of calcium requiremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

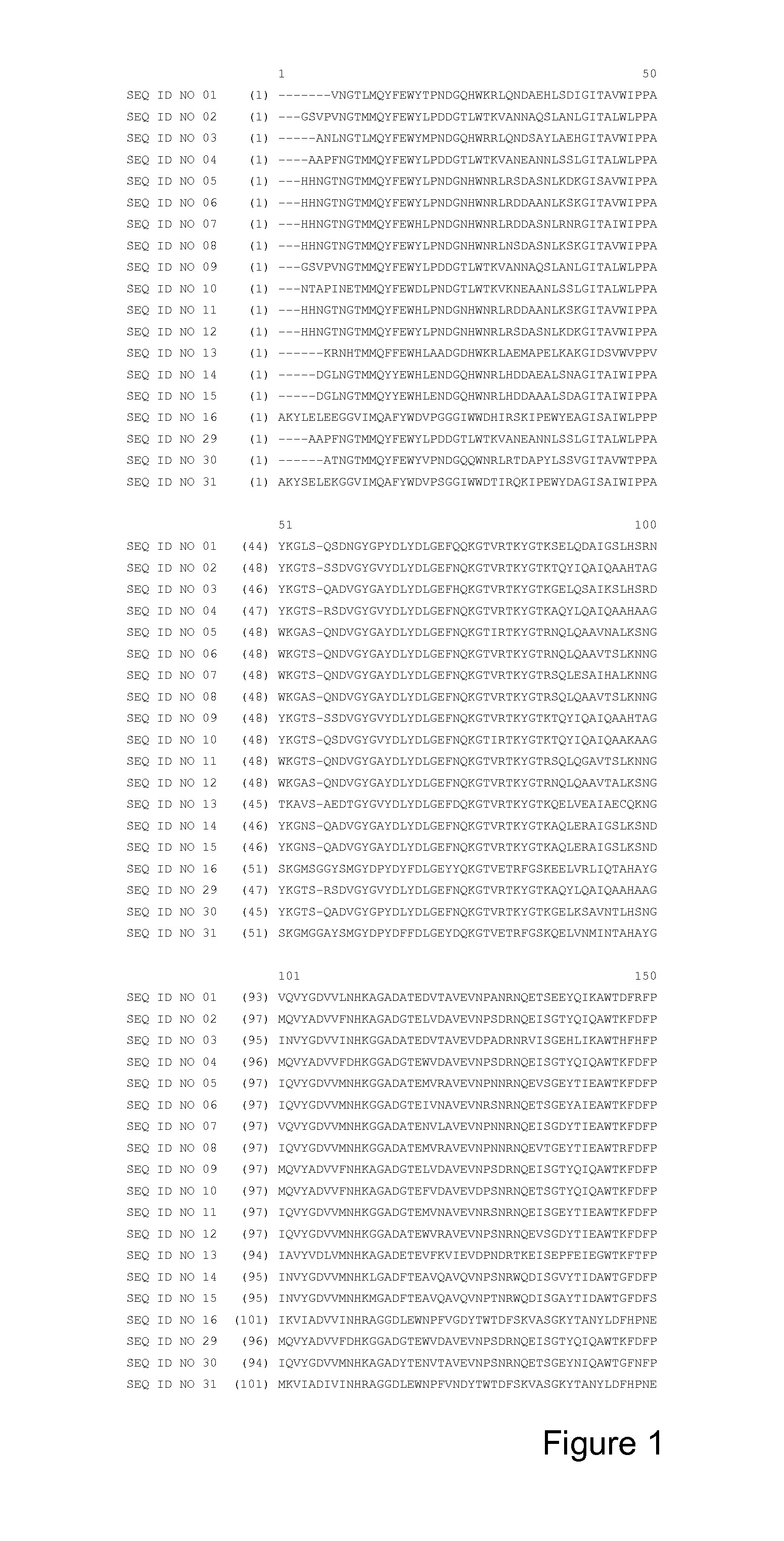

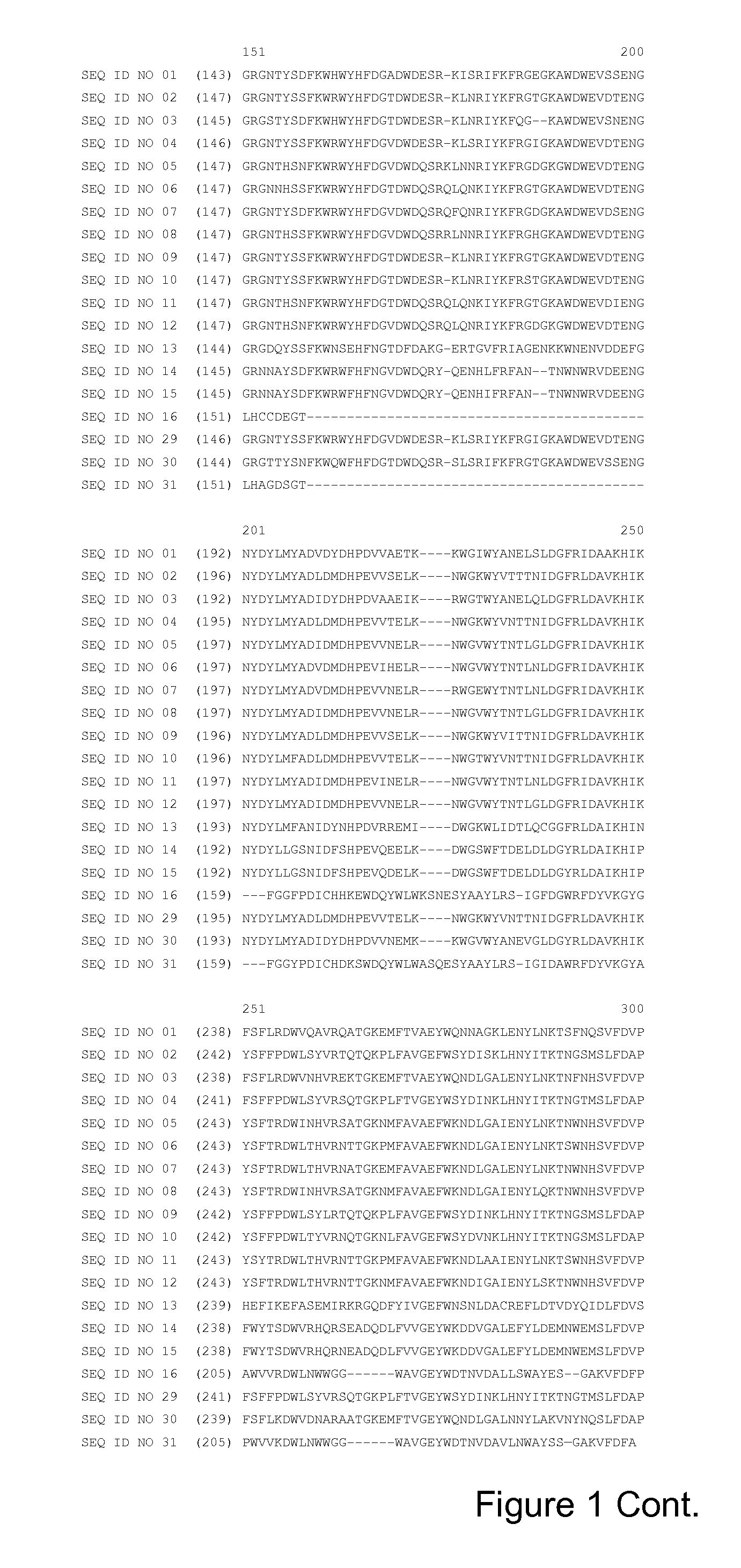

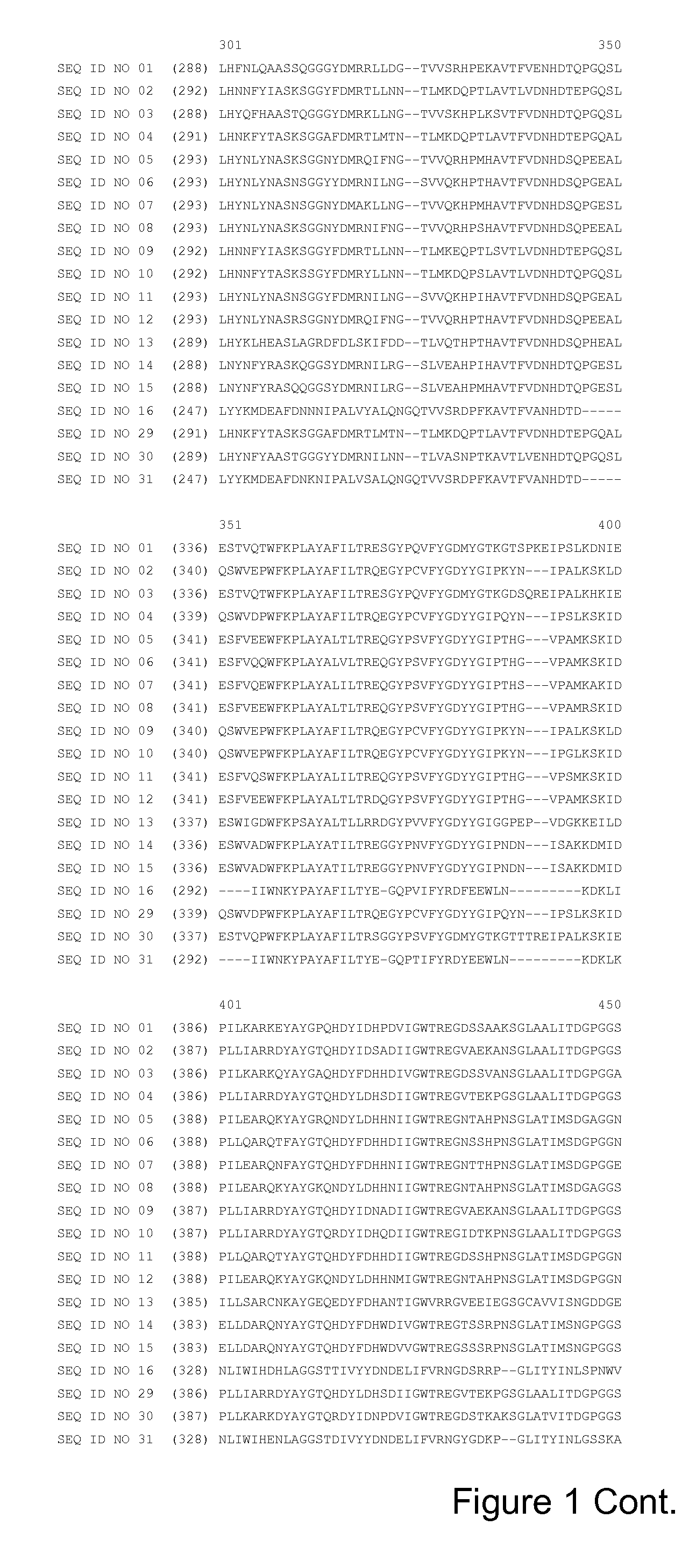

Image

Examples

example 1

Preparation of Hybrids

[0438]The following hybrids of the calcium-sensitive alpha-amylase having the sequence shown in SEQ ID NO: 7 and the calcium-insensitive alpha-amylase having the sequence shown in SEQ ID NO: 13 were prepared.

Hybrid 1: the amino acid residues 106-215 of SEQ ID NO: 7 were removed and replaced with the amino acid residues 103-211 of SEQ ID NO: 13, which results in SEQ ID NO: 17, and the following alterations were introduced: E182*, N183*, E188W, N189E and D192T (using SEQ ID NO: 17 numbering), which correspond to E181*, N182*, E187W, N188E and D191T using SEQ ID NO: 27 numbering. The sequence of this hybrid is shown in SEQ ID NO: 18.

Hybrid 2: the amino acid residues 106-214 of SEQ ID NO: 7 were removed and replaced with the amino acid residues 103-210 of SEQ ID NO: 13, which results in SEQ ID NO: 19, and the following alterations were introduced: E182*, N183*, E188W, N189E and D192T (using SEQ ID NO: 19 numbering), which correspond to E181*, N182*, E187W, N188E an...

example 2

Stability in the Presence of Chelator

[0439]Enzyme samples were incubated in buffer pH 8.0 (50 mM EPPS, 0.01% TRITON®X100, pH 8.0) with 1.5% final concentration of DTPA at 49° C. for 1 hour and reference samples were incubated at 4° C. for 1 hour. In addition, enzyme samples were incubated in buffer pH 10.0 (50 mM EPPS, 0.01% TRITON® X100, pH 10.0) with 1.5% final concentration of DTPA at 42° C. for 1 hour and reference samples were incubated at 4° C. for 1 hour.

[0440]For the determination of amylase stability in buffer pH 8 and pH 10 with DTPA the enzymes to be tested were adjusted to 0.25 and 0.5 mg enzyme protein / mL by diluting in 5 mM EPPS, 0.01% TRITON® X100, pH 8.0.

[0441]160 microliters stability buffer (50 mM EPPS, 0.01% TRITON® X100, 1.875% DTPA, pH 8.0 or pH 10.0) and 40 microliters of the amylase solution were transferred to a 96-well PCR microtiter plate in duplicate and the content was mixed for 1 minute. Final concentration of DTPA was 1.5% in each well. 20 microliters f...

example 3

Additional Alpha-Amylases

[0444]The following alpha-amylases were prepared:

Hybrid 4: the amino acid residues 106-212 of SEQ ID NO: 5 were removed and replaced with the amino acid residues 103-208 of SEQ ID NO: 13, which results in SEQ ID NO: 23, and the following alterations were introduced: E182*, N183*, E188W, N189E and D192T (using SEQ ID NO: 23 numbering), which correspond to E181*, N182*, E187W, N188E and D191T in SEQ ID NO: 27 numbering. The sequence of this hybrid is shown in SEQ ID NO: 24.

Hybrid 5: the amino acid residues 106-212 of SEQ ID NO: 8 were removed and replaced with the amino acid residues 103-208 of SEQ ID NO: 13, which results in SEQ ID NO: 25, and the following alterations were introduced: E182*, N183*, E188W, N189E and D192T (using SEQ ID NO: 25 numbering), which correspond to E181*, N182*, E187W, N188E and D191T in SEQ ID NO: 27 numbering. The sequence of this hybrid is shown in SEQ ID NO: 26.

Hybrids 4 and 5 (SEQ ID NOS: 24 and 26), a variant of SEQ ID NO: 5 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| nucleic acid | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| crystal structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com