Driving control of a reciprocating cpr apparatus

a reciprocating cpr and driving control technology, applied in the field of driving control of reciprocating cpr apparatus, can solve the problems of limited gas supply, damage to the ribs and soft tissues of the chest, insufficient to restore circulation and oxygenation, etc., and achieve the effect of reducing the consumption of driving gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

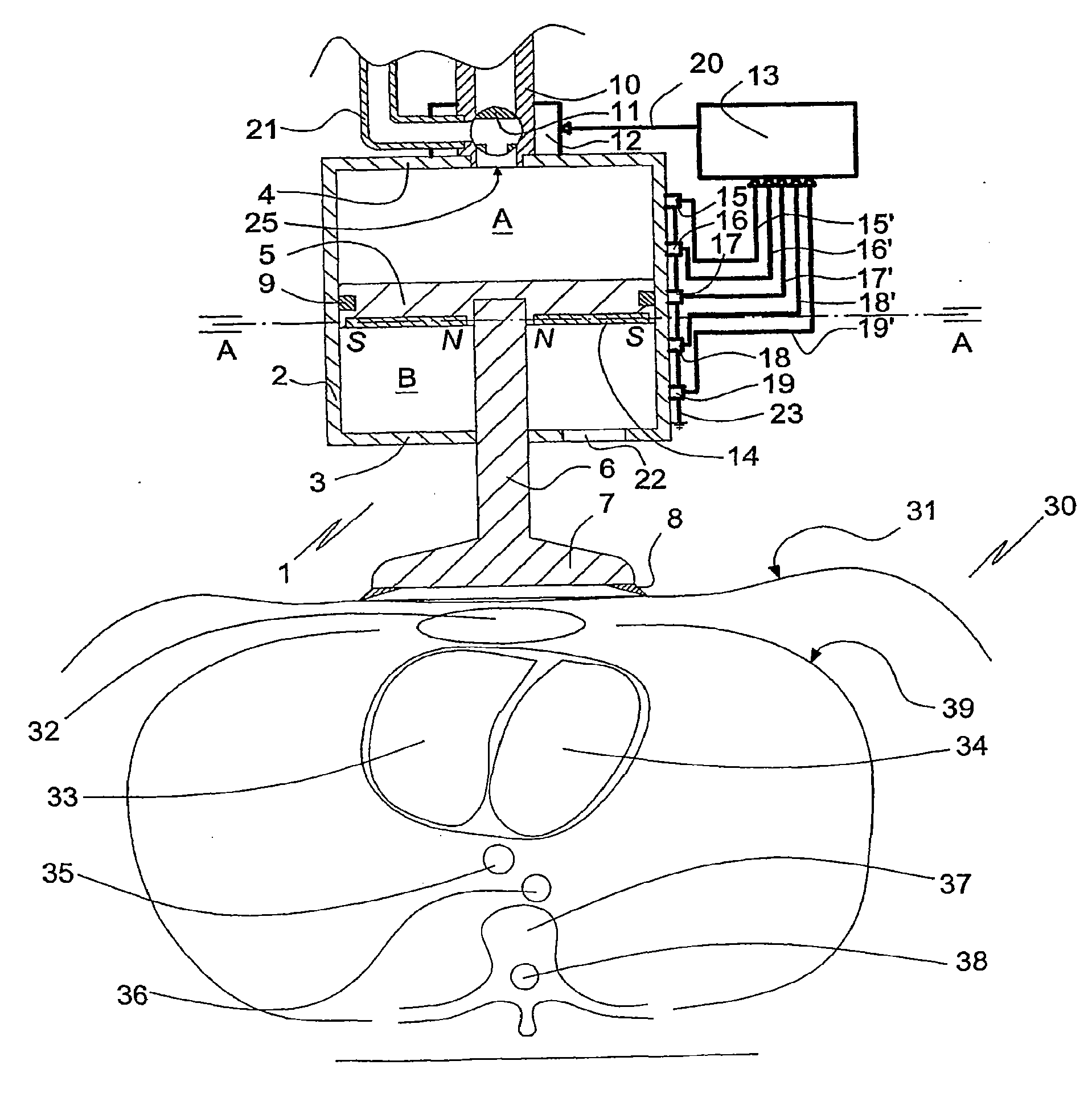

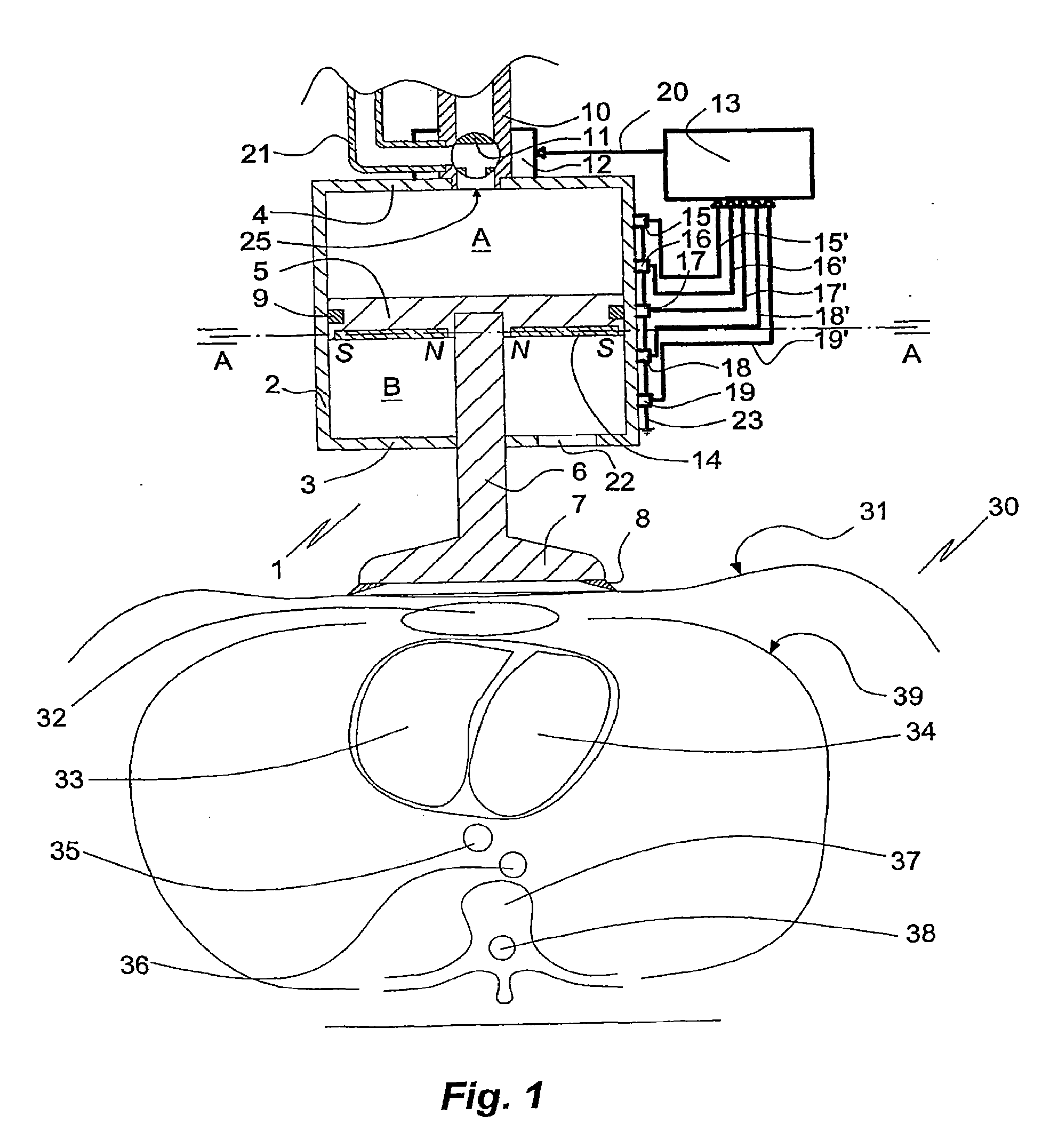

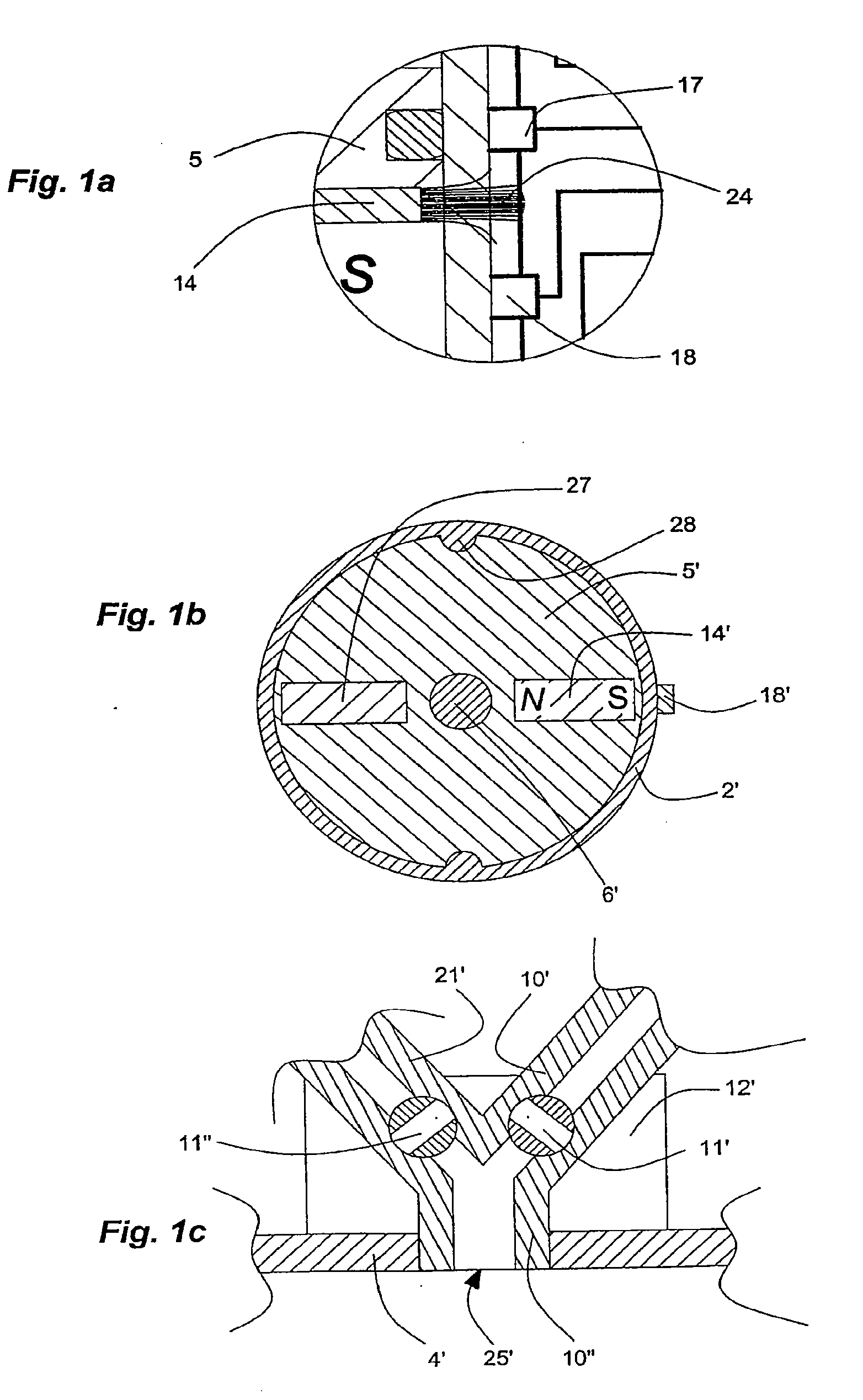

[0046]The embodiment of the apparatus 1 of the invention shown in FIGS. 1-2h comprises a cylinder housing of a diamagnetic material having a side wall 2, a bottom 3 and a top wall 4. A piston 5 with a circumferential sealing 9 is mounted in the housing and defines an upper compartment A and a lower compartment B. A plunger 6 extends downwards from the centre of the piston 5, passing through a central bore in the bottom 3 of the housing. At its free end the plunger 6 carries a chest compression pad 7 provided with a flexible circumferential lip 8. The piston 5 / plunger 6 / compression pad 7 is mounted displaceably in the cylinder housing. A neodymium magnet ring 14 is mounted at the lower face of the piston 5 with its south pole S facing the side wall 2. An array of unipolar Hall-Effect digital switches (“unipolar Hall switches”) 15, 16, 17, 18, 19 is mounted at the outer wall of the cylinder 1 in an axial direction. The unipolar Hall switches 15, 16, 17, 18, 19 are characterized by the...

example 2

Solenoid Valve Control Program

[0060]In the following an example of a simple main valve control program is provided (Table 1). In the example consideration is given to one Hall effect element (Hall switch), which is placed at about a desired level of piston 5 / plunger 6 / rod 7 assembly stop (bottom level). Time open for the decompression main valve is set to 300 ms; while this parameter is fixed in the Example, it could be controlled in precisely the same way as time open for the compression main valve.

TABLE 1Initialize:sett_open = 300[ms]setadjust = true(Parallel process #1, controls main valves)While true dois_down = falsemain_valve_comp = true / opens compression main valvewait t_open / holds main valve open for t_open msmain_valve_comp = false / closes compression main valvewait 300 − t_open / wait the rest of the compressionphasemain_valve_decomp = true / opens decompression main valvewait 300 / waits until whole cycle is completemain_valve_decomp = false / closes decompression main valv...

example 3

[0062]The effect of the method of the invention in the control of compressed driving gas is demonstrated by three experiments illustrated in FIGS. 5a-5c. The experiments were carried out with an air-driven reciprocating CPR device mounted on a test bench. The CPR apparatus comprises a compression cylinder 208 comprising an upper compartment 219 and a lower compartment 220 delimited in respect of each other by a piston 216 arranged displaceably in the cylinder 208. The apparatus further comprises a breast compression pad 210 attached to the piston 216 via a shaft 211, a valve control unit 212 with a valve manifold, and a gas line 213 supplying driving gas from source of compressed gas (not shown) to the compression cylinder via the valve control unit 212. The stroke (str) of the piston 216 is limited to 55 mm by means of upper 217 and lower 218 stroke limiters disposed in the upper and lower compartments, 219, 220, respectively. The gas pressure in the upper compartment 219 is measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com