Apparatus for heating fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

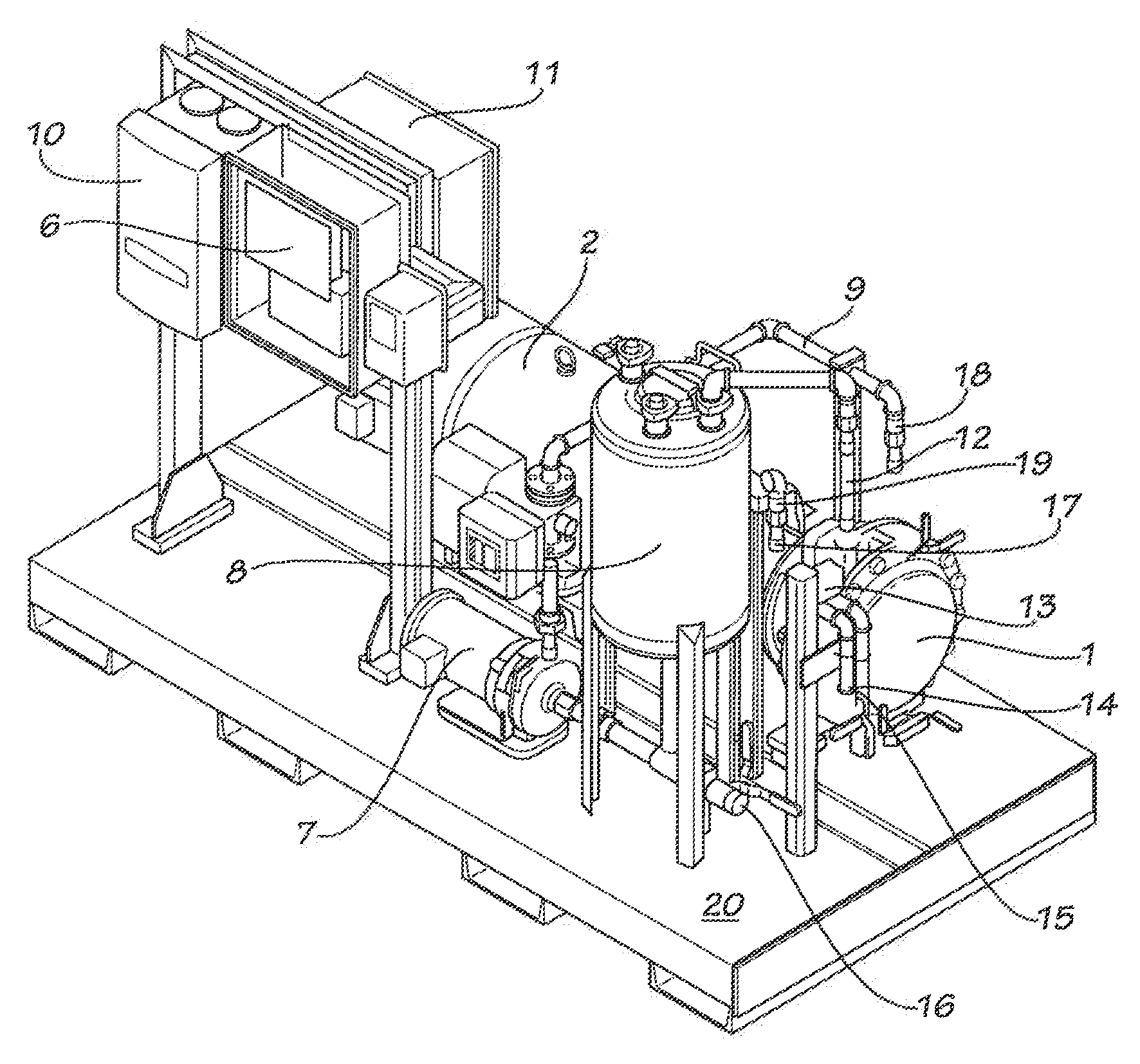

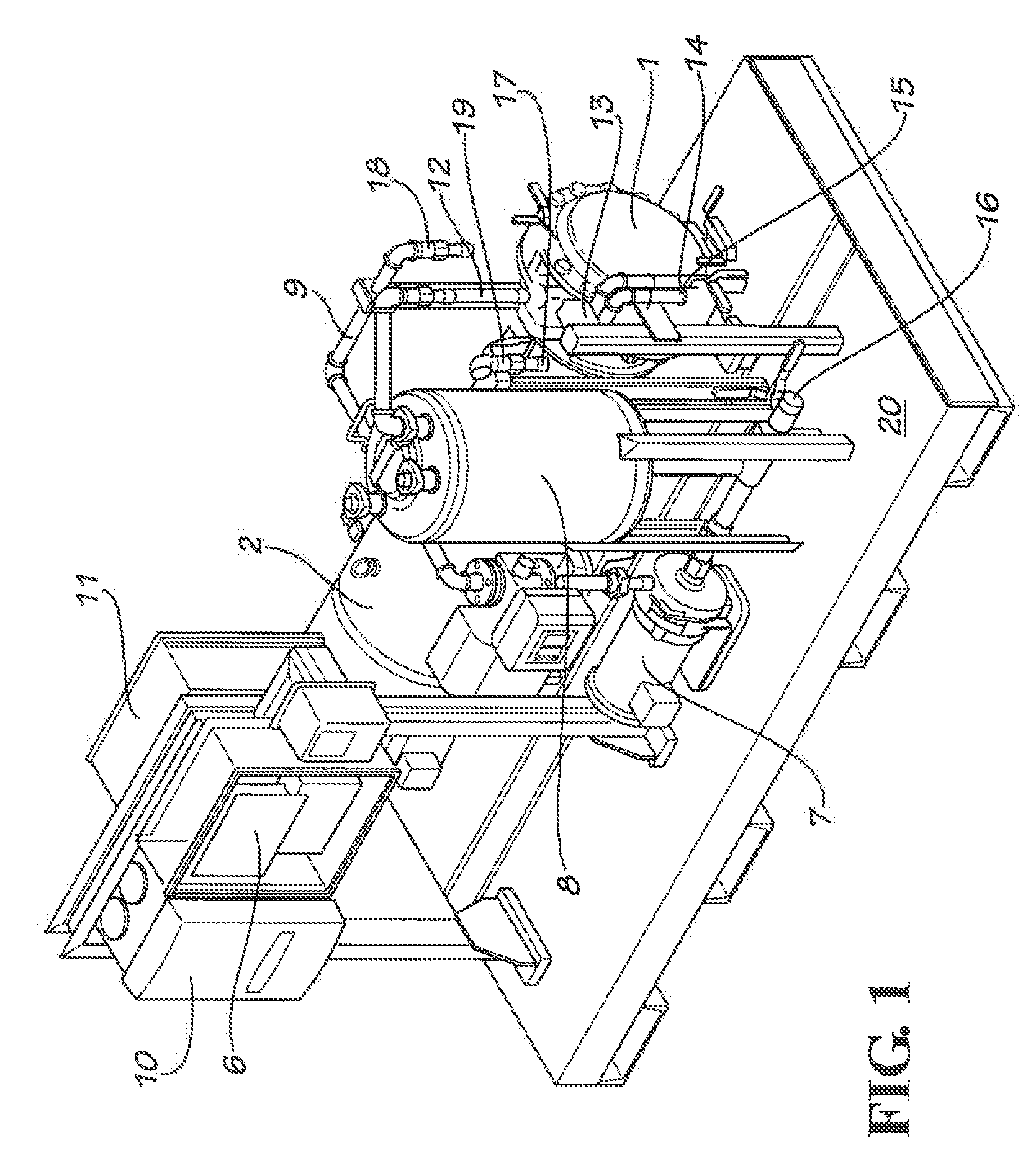

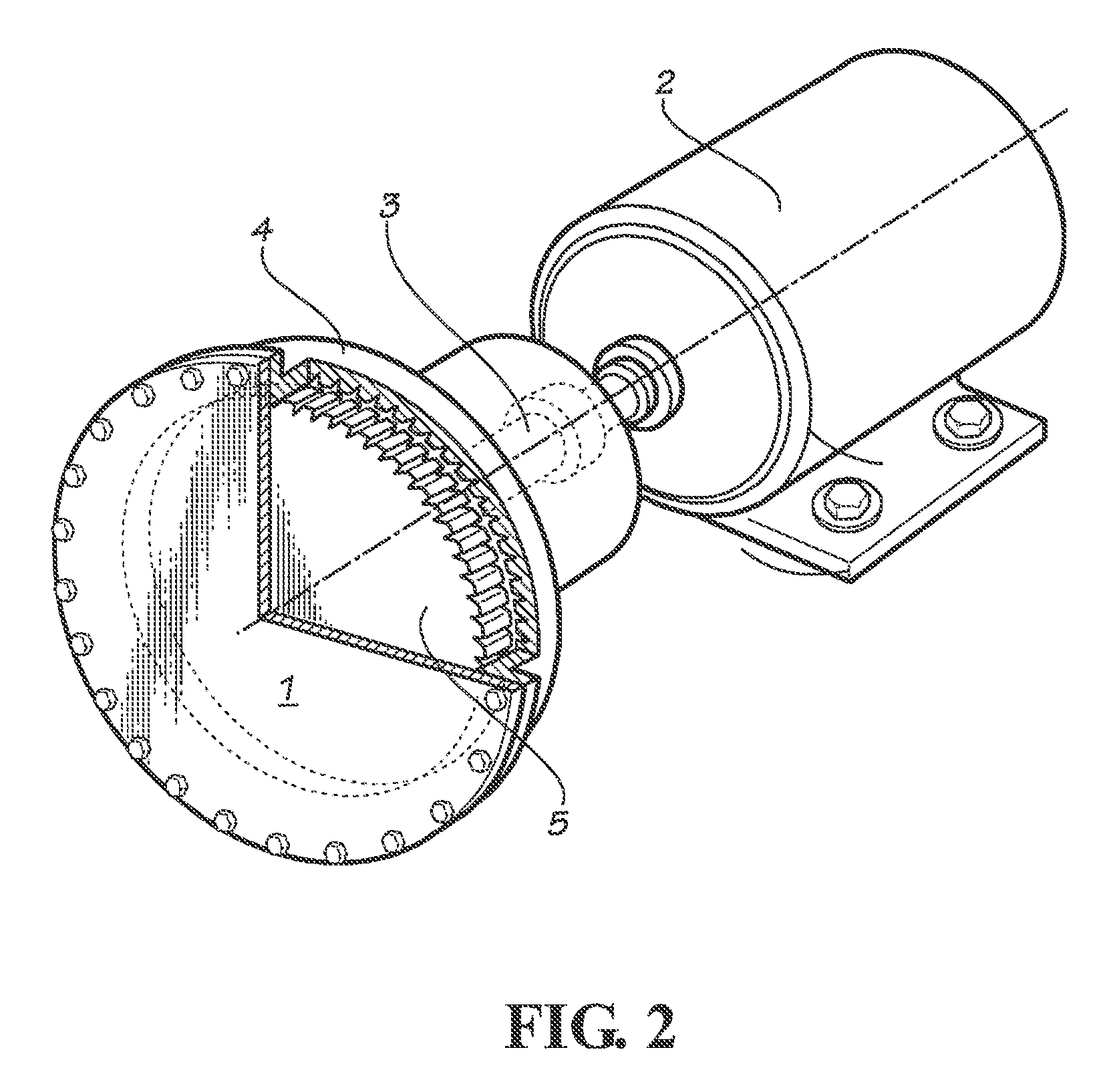

[0023]FIG. 1 shows the overall configuration of the preferred embodiment of a system 20 designed to purify contaminated water, such as frac water, in batches. The contaminated fluid is first pumped into tank 8. From the tank, the fluid passes through tank outlet line 17 to the inlet of cavitation generator 1. As shown in FIG. 2 and as described above, the cavitation generator consists of two primary parts, a rotor housing 4 and a rotor 5. The rotor 5 is driven by a shaft 3 that is coupled to a motor 2. In the preferred embodiment, an electric motor is used. The size of the motor is dependent on the size of the unit; typically, 500 or 1000 horsepower motors would be used for applications requiring purification of up to 100,000 gallons per day. One skilled in the art will realize that any type of motive power capable of providing torque to a shaft can be substituted for an electric motor, although in these cases additional mechanical complexity may be required in the form of gears to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com