Method and apparatus for high aspect ratio dielectric etch

a dielectric etching and high aspect ratio technology, applied in the direction of electrolysis components, vacuum evaporation coatings, coatings, etc., can solve the problems of twisting or distortion of high aspect ratio (uhar) etching, ever-increasing aspect ratio needed to meet design requirements, etc., and achieve high aspect ratio features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0043]In an example of the invention, the dielectric layer may be silicon oxide based, where the dielectric layer is mainly formed of silicon oxide, with smaller amounts of other types of substance mixed in. More preferably, the dielectric layer is a low-k dielectric, such as organosilicate glass. In another embodiment the dielectric layer is an organic dielectric layer.

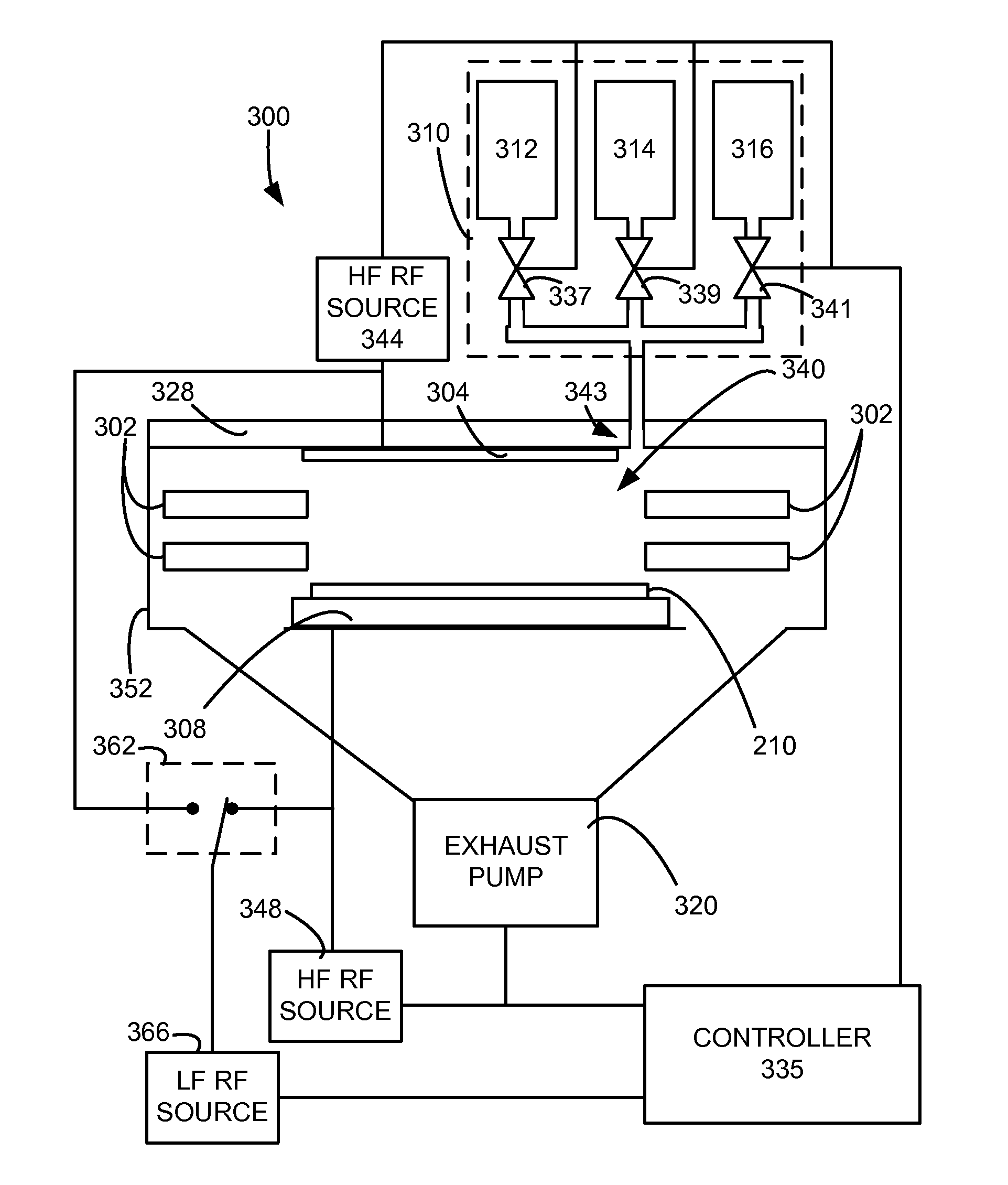

[0044]In an example recipe of a silicon oxide based dielectric etch, the etch chamber pressure is 30 milli-Torr (mTorr). The etch gas comprises 150 standard cubic centimeters per minute (sccm) of argon (Ar), 4 sccm of C4F6, 18 sccm of C4F8, and 17 to 25 sccm of oxygen (O2). The source HF RF power is at 2000 watts (W) with a frequency of 27 MHz. The LF RF power is 4000 W with a frequency of 2 MHz. The LF RF power is alternated between the upper and lower electrodes. The 2 Mhz power delivered to the upper and lower electrode may not be of the same magnitude and can be adjusted for optimal results.

[0045]Preferably the L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| sheath voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com