Method and apparatus for manufacturing carbon nanostructure, and carbon nanostructure assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

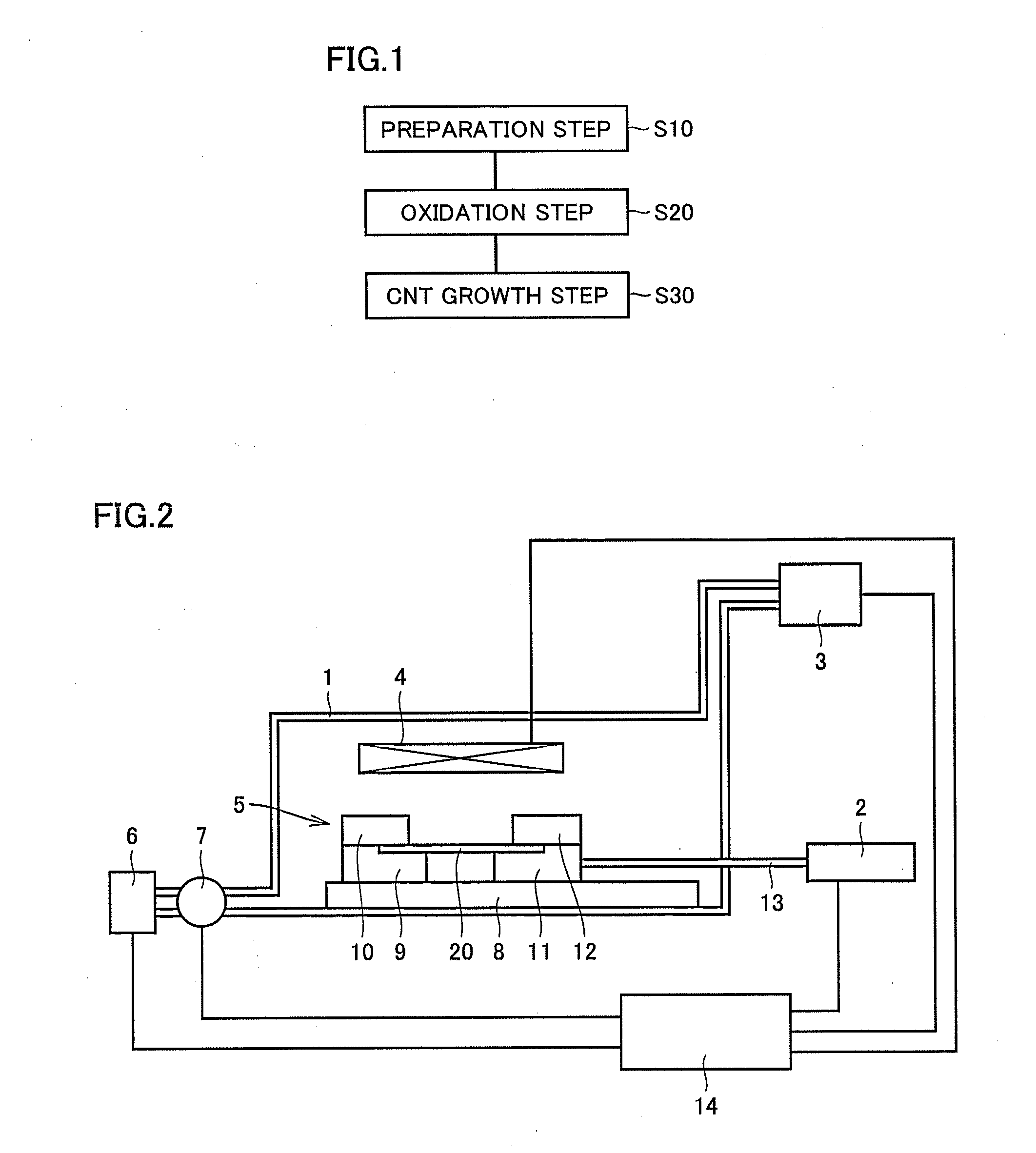

[0037]A method for manufacturing a carbon nanostructure according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 4.

[0038]Referring to FIG. 1, in the method for manufacturing the carbon nanostructure according to the present invention, a preparation step (S10) is first performed. In this step (S10), a base body formed of a catalyst member including a catalyst and a separation member that are in contact with or integral with each other is prepared.

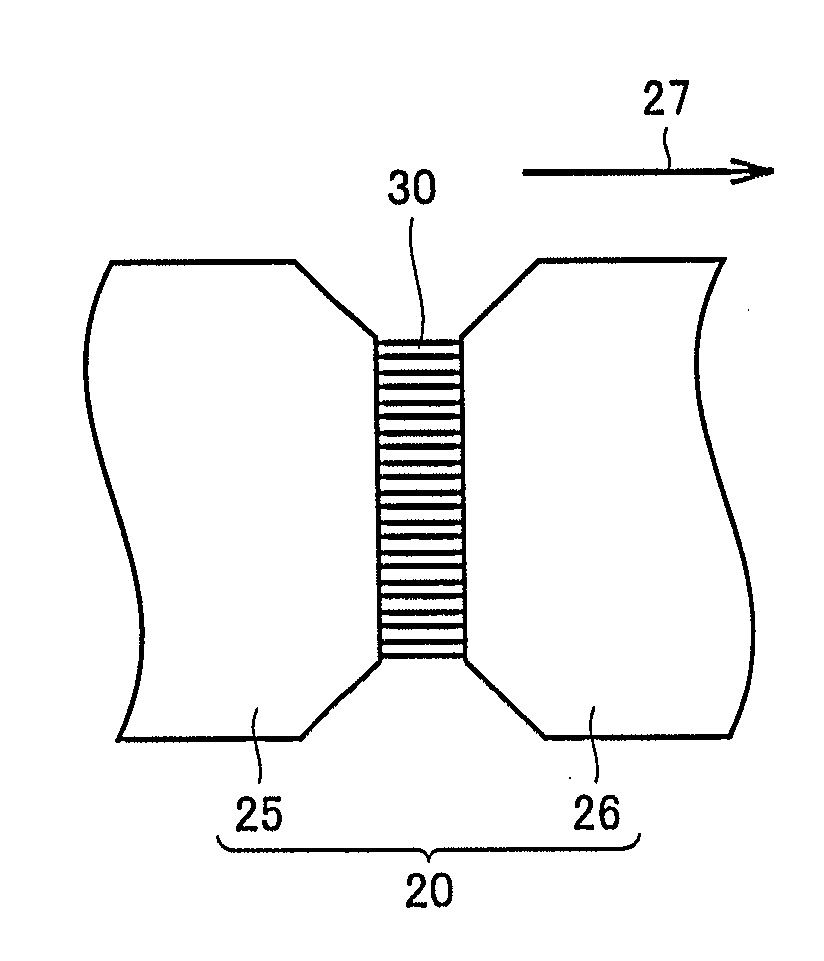

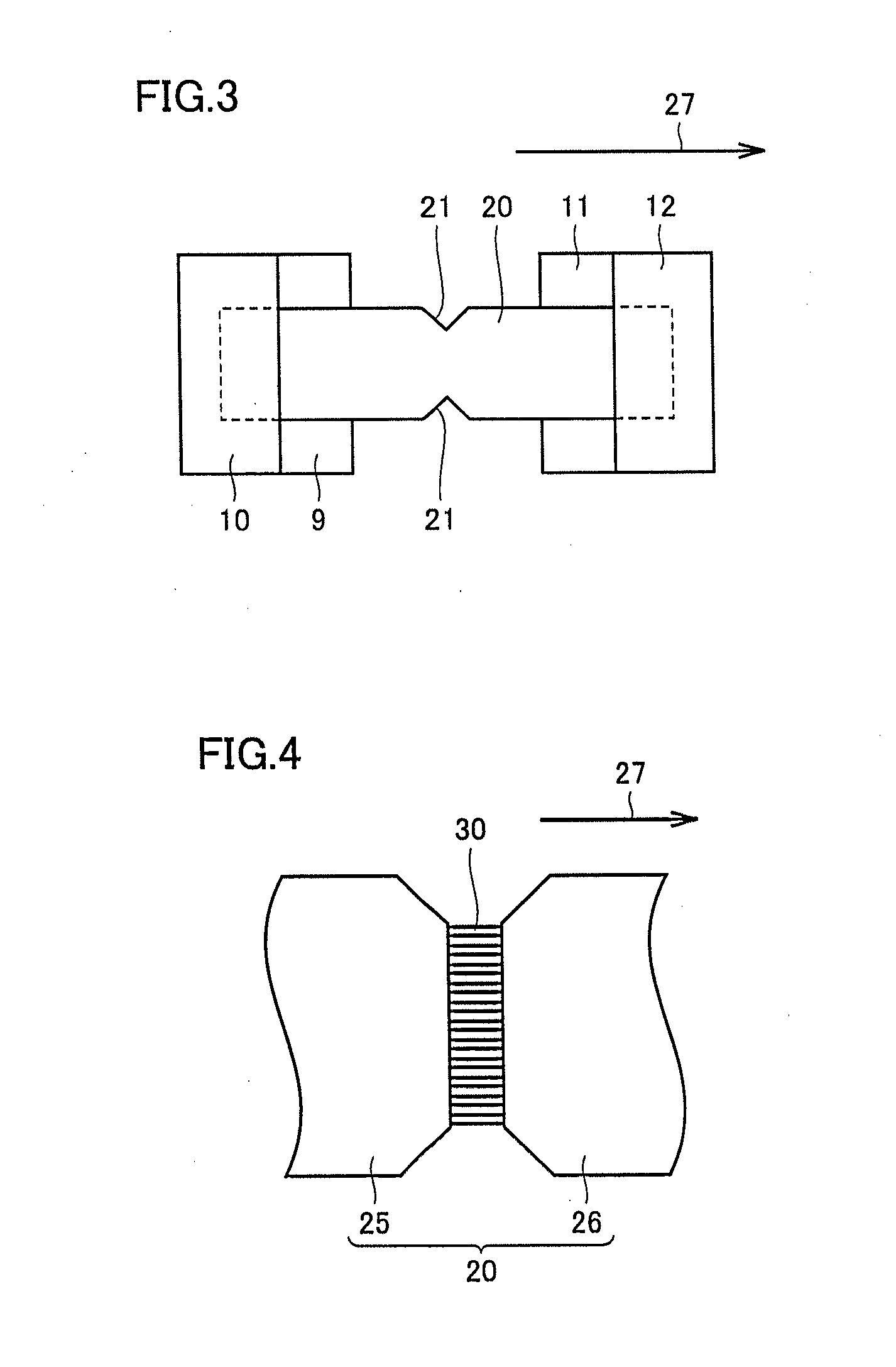

[0039]As shown in FIGS. 2 and 3, a metal sheet (metal foil) serving as a catalyst can be used as a base body 20. Pure iron, nickel, cobalt and the like can, for example, be used as the metal. A notch 21, which is a recessed portion for defining a position of fracture in a CNT growth step (S30) (refer to FIG. 1) described below, is preferably formed in base body 20. When the metal foil as shown in FIGS. 2 and 3 is used as base body 20, the metal foil forms the above-described catalyst member and ...

second embodiment

[0049]An apparatus for manufacturing a carbon nanostructure according to a second embodiment of the present invention will be described with reference to FIG. 5.

[0050]Referring to FIG. 5, the apparatus for manufacturing the carbon nanostructure includes reaction chamber 1, heating member 4 arranged outside reaction chamber 1, a diaphragm 31 connected to a catalyst member 35 forming base body 20 in order to hold catalyst member 35 at a position facing heating member 4, a separation member 36 arranged in contact with catalyst member 35, driving member 2 coupled to separation member 36 by coupling rod 13, the gas supply portion (not shown) for supplying the source gas and the like to reaction chamber 1, pump 7 and discharge portion 6 for discharging the gas from reaction chamber 1, and the controller (not shown) for controlling heating member 4, the gas supply portion, driving member 2, pump 7, and discharge portion 6. Catalyst member 35 has, for example, a circular planar shape, and d...

third embodiment

[0057]An apparatus for manufacturing a carbon nanostructure according to a third embodiment of the present invention will be described with reference to FIG. 7.

[0058]Referring to FIG. 7, the apparatus for manufacturing the carbon nanostructure basically includes a configuration similar to that of the apparatus for manufacturing the carbon nanostructure shown in FIG. 5, although the former is different from the latter in terms of a configuration of used base body 20. In other words, iron foil is used as catalyst member 35 forming base body 20, and separation member 36 is configured by a catalyst thin film 41 formed of an iron foil film, and two fixing members 42 and 43 for sandwiching and holding catalyst thin film 41. Separation member 36 is grasped by a grasp member 44. Grasp member 44 is connected to coupling rod 13.

[0059]Next, a method for manufacturing the carbon nanostructure using the apparatus for manufacturing the carbon nanostructure shown in FIG. 7 will be described. Altho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com