Process for the recovery of crude

a technology of crude oil and process, applied in the field of crude oil production, can solve the problems of complex process, large complex facilities, etc., and achieve the effects of increasing stabilized liquid production, maximizing product stream, and minimizing the amount of c3 components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

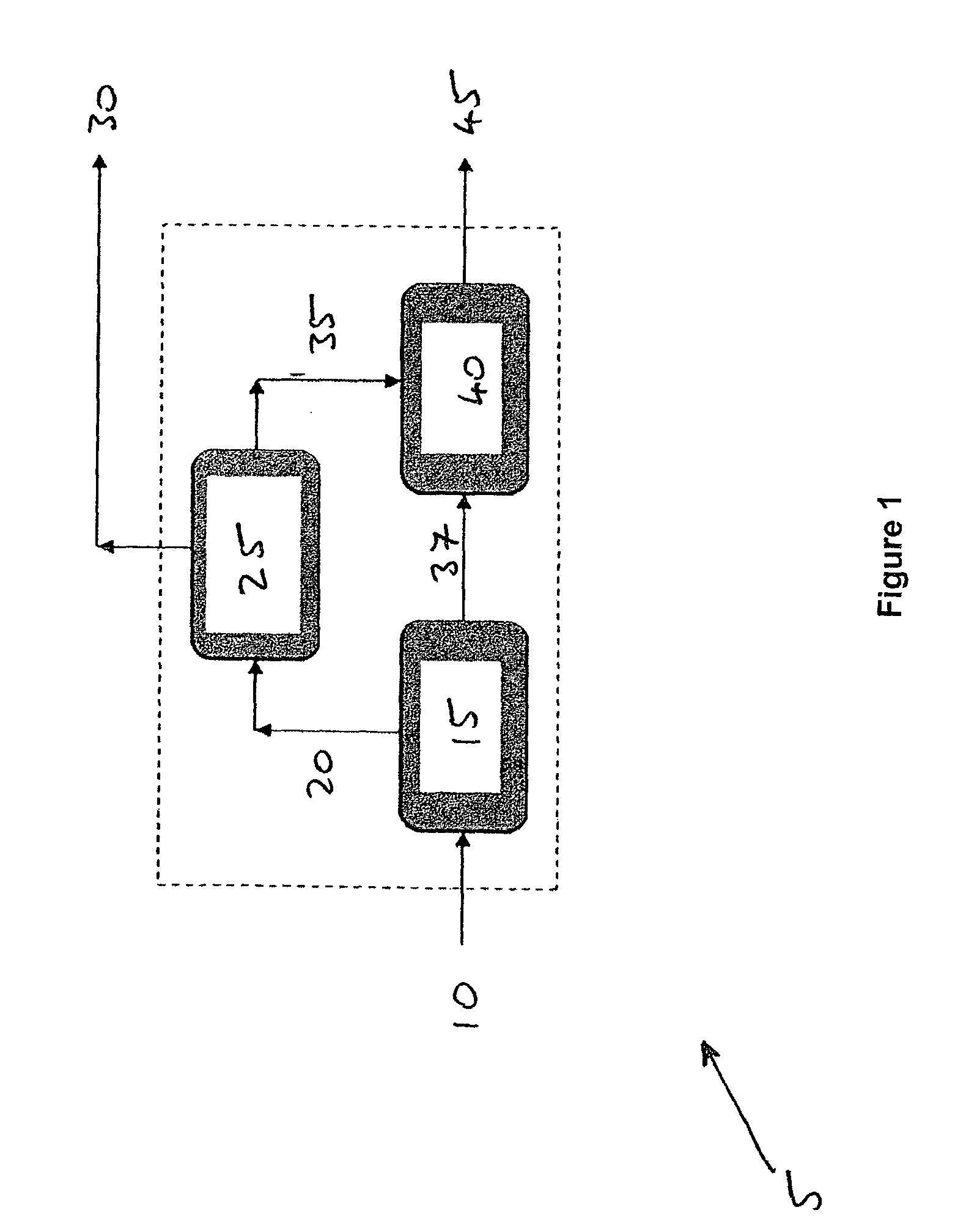

Image

Examples

example

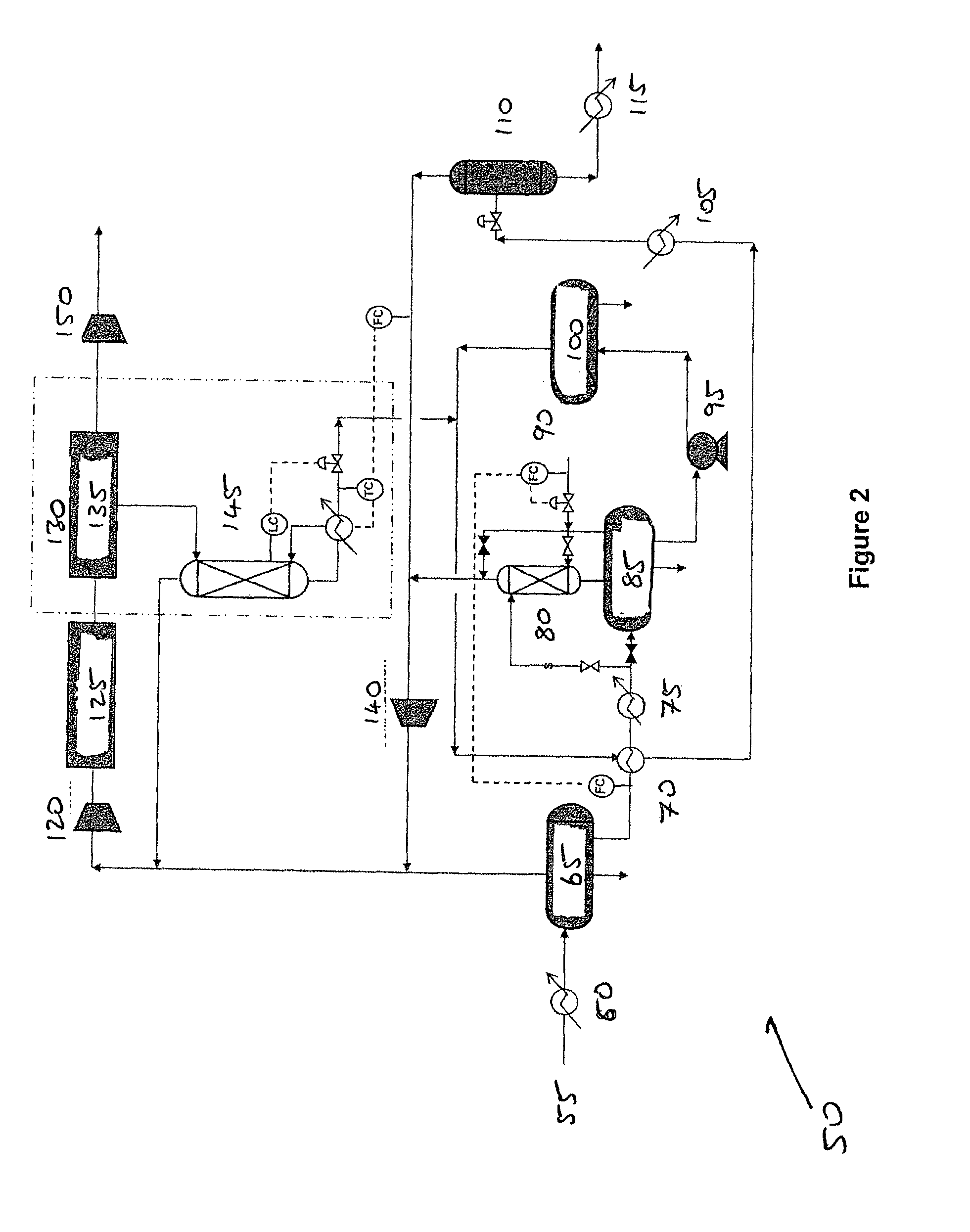

[0075]The process of the present invention has application in production facilities where crude and gas are produced simultaneously and where it is not economical to install conventional NGL extraction facilities. This includes onshore and offshore facilities that simultaneously produce and process crude with associated and non-associated gas. The case study in the following sub-section demonstrates how the process of the present invention can be used on facilities that produce and process non-associated gas and crude in parallel.

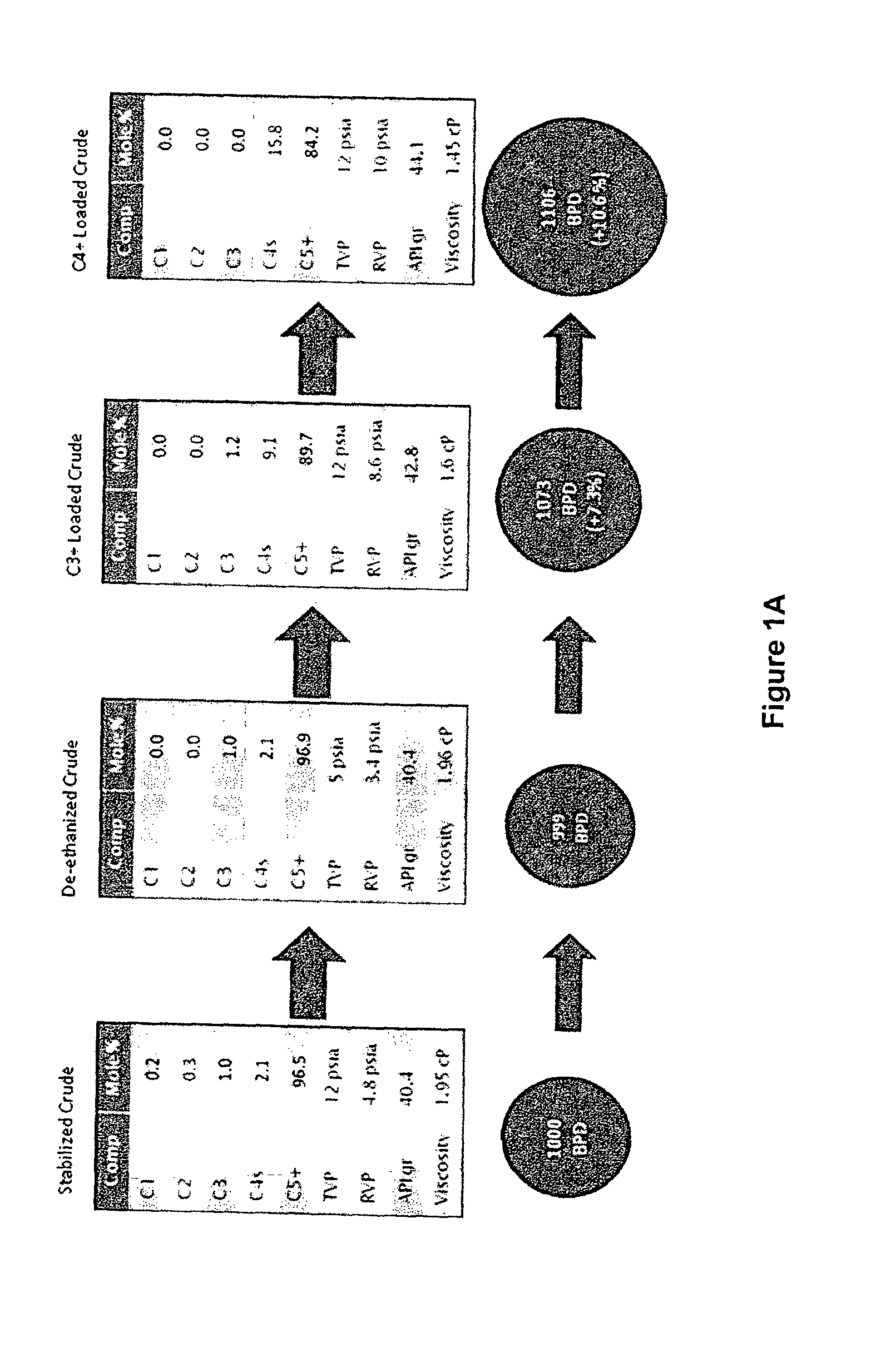

[0076]A case study is carried out for a gas well stream of 160 MMscfd of non-associated gas and 16,000 bpd of condensate; another feed from oil well of 21,000 bpd of crude oil and 11 MMscfd associated gas. Four different processing facilities are considered, they are:[0077]i. LPG fractionation[0078]ii. Conventional multi stage separation and stabilization[0079]iii. Conventional multi stage separation plus condensate stabilization[0080]iv. One embodiment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com