Methods and apparatus for cleaning flip chip assemblies

a technology of flip chip and assembly, which is applied in the direction of cleaning equipment, chemistry apparatus and processes, cleaning using liquids, etc., can solve the problems of difficult to remove charred and caramelized flux residues, complex cleaning of flip chip assemblies, and difficult to clean conventional surfaces, etc., to increase the rotation speed and increase the centrifugal force. , the effect of increasing the rotation speed of the chuck assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Preferred embodiments of this invention will be described in detail hereinafter with reference to the drawings. The embodiments of the present invention described are not limit the invention to the precise forms disclosed in the following detailed description.

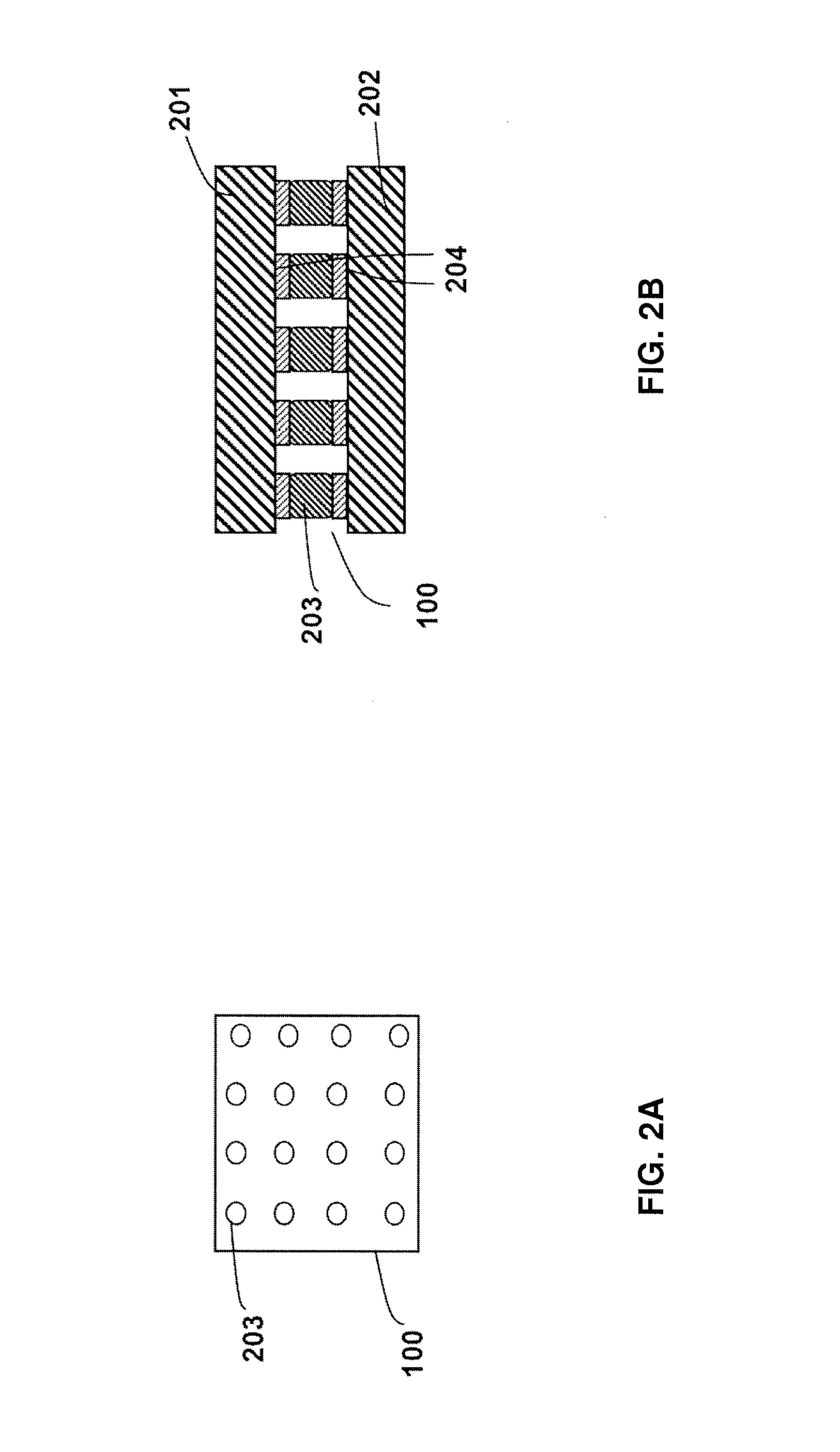

[0041]FIGS. 2a-2b show top section view and cross-sectional view of a flip chip assembly 100 of a known type, respectively. In some case, the illustrative structure represented in FIGS. 2a-2b is just a part of a flip chip assembly. As depicted, chip 100 including two chip bond pads 201 and 202, which are coupled face-down to each other by an array of solder balls 203. The shape of the pads can be square, rectangular, circular or other shapes depending on specific purpose. During soldering, there will be flux residue or other contaminants 204 that remain on the surface of the solder balls 203 and the surface of the bonding pads 201 and 202. These residues must be cleaned sufficiently, or else it will be left as inclusion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com