Pipe provided with corrosion prevention layer on the outside surface, process for production of the same, and process for production of alloy wires used for the corrosion prevention layer

a corrosion prevention layer and pipe technology, applied in the direction of coatings, mechanical devices, transportation and packaging, etc., can solve the problems of hardly maintaining the sacrificial anode function of zinc, the corrosion of metal pipes progressing from the scratched portions, and the corrosion of metal pipes with a high ionization tendency, so as to achieve the effect of improving corrosion prevention performance, reducing the number of work, and improving corrosion prevention performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0057]Hereinafter, Examples of the present invention are described. It is to be noted that in following Examples, Comparative Examples, the evaluations of various physical properties were performed as follows.

[0058](1) Workability into Wire

[0059]An alloy ingot of 47 mm in diameter X 350 mm in length was prepared and the workability into wire was evaluated by measuring the Vickers hardness. The alloy ingot after the hardness measurement was forged so as to have a reduced diameter of 10 mm and further wiredrawn so as to have a diameter of 1.6 mm, and thus the workability was evaluated on the basis of the following standards.

[0060]G (Good): Wiredrawing can be performed to a diameter of 1.6 mm.

[0061]P (Poor): Breakage occurs during wiredrawing.

[0062](2) Corrosion Resistance

[0063]A corrosion resistance test was performed in the following manner. Specifically, a 150 mm×70 mm×2 mm sand-blast steel plate was used as a specimen. On this plate, a 20 to 30-μm thick sprayed coating was formed a...

examples 43 to 53

[0087]As shown in Table 4, in each of Examples 43 to 53, a Zn—Sn—Mg wire was used as a first wire and a Zn wire was used as a second wire, and simultaneously the first wire and the second wire were arc sprayed. The results thus obtained are shown in Table 4. In this tabular presentation, in the same manner as in above-described Examples, in each of Examples 43 to 53, when Ti, Co, Ni and P were added and the salt spray test was performed, in any of the cases in which any one of Ti, Co, Ni and P was singly added, the same evaluation results were obtained, by varying the addition amount, on the time periods until red rust occurred. Therefore, also in Table 4, for simplicity, only one typical example is shown for each of Examples 43 to 53.

TABLE 4Components(% by mass)ZnSnMgSpray conditionsHardness (Hv)Workability into wireEx. 43Balance20.02Zn—4Sn—0.04Mg wire and Zn——wireEx. 44Balance23.00Zn—4Sn—6.0Mg wire——and Zn wireEx. 45Balance100.02Zn—20Sn—0.04Mg——wire and Zn wireEx. 46Balance103.00Z...

example 54

[0104]Hereinafter, an example of the process for production of an alloy wire of the present invention is described.

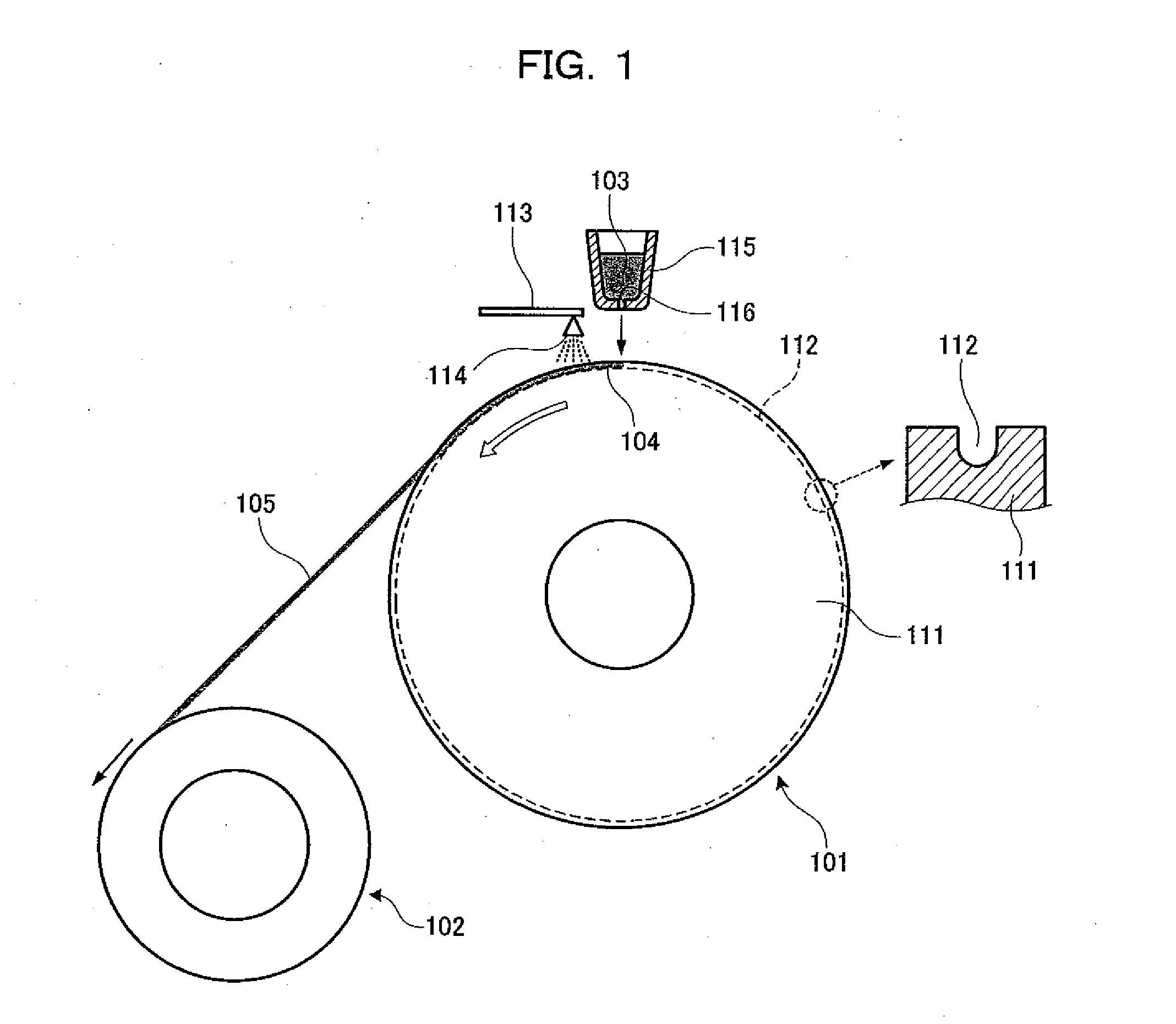

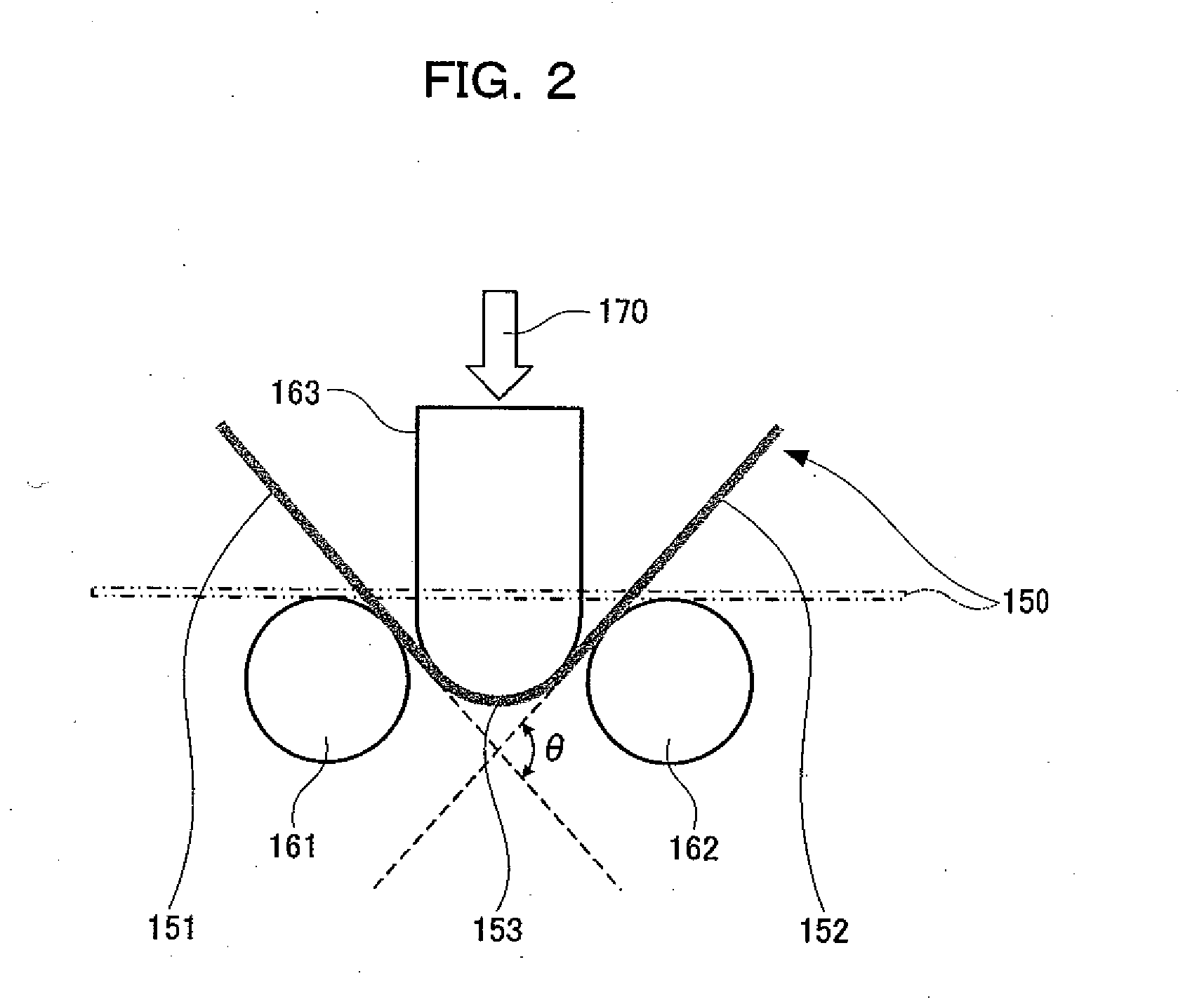

[0105]By using an apparatus shown in FIG. 1, under the below-described conditions, an alloy wire 105 in which crystals were refined, the ductility thereof was improved and the diameter thereof was 10 mm was obtained. Then, the alloy wire 105 was worked into an alloy wire having a diameter of 1.6 mm with a not-shown wiredrawing machine.

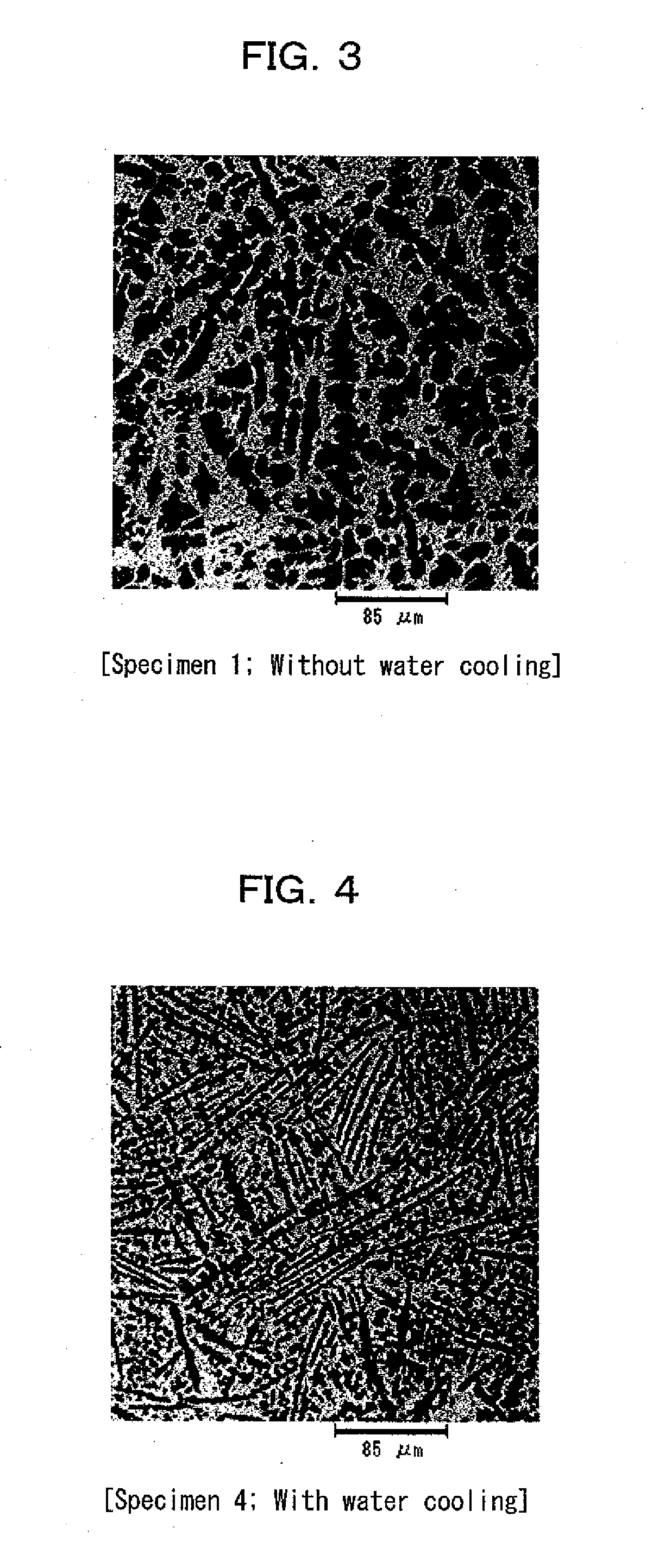

[0106]Specifically, in the above-described production process, the timing of spraying cooling water was altered and quenching was performed. More specifically, as shown in Table 5, the timing of spraying cooling water (hereinafter, referred to as “water cooling timing”) was varied, and thus the specimens 1 to 4 were produced.

[0107]In other words, Zn, Sn and Mg were melted at 450° C., and these molten materials were mixed in such a way that the content of Sn was 30% by mass, the content of Mg was 0.3% by mass and the balance was composed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com