Polycarbonate resin and transparent film formed therefrom

a technology of polycarbonate resin and transparent film, which is applied in the direction of polarising elements, instruments, transportation and packaging, etc., can solve the problems of petroleum resource depletion, achieve excellent film formation properties, moderate glass transition temperature, and low photoelastic coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

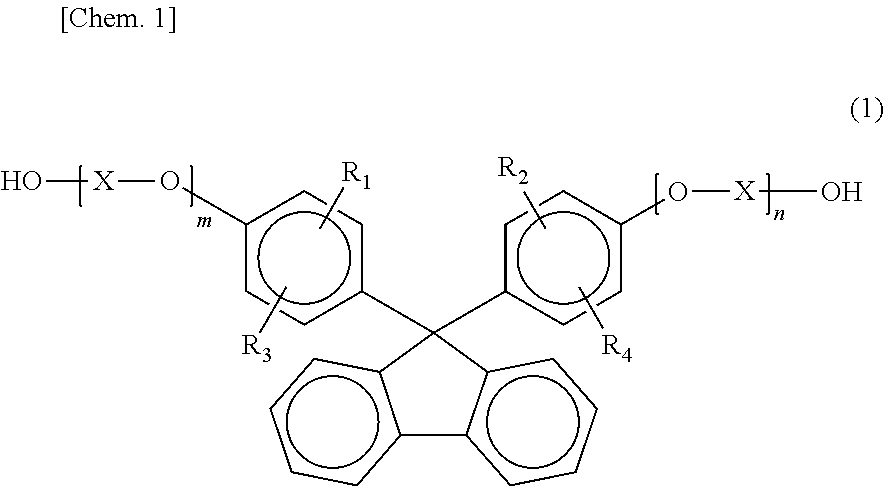

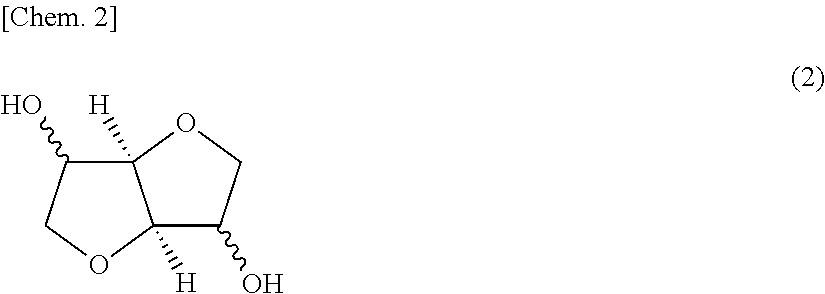

[0115]Into a reaction vessel were introduced 26.2 parts by weight of isosorbide (hereinafter often abbreviated to “ISB”), 100.5 parts by weight of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene (hereinafter often abbreviated to “BHEPF”), 10.7 parts by weight of 1,4-cyclohexanedimethanol (hereinafter often abbreviated to “1,4-CHDM”), 105.1 parts by weight of diphenyl carbonate (hereinafter often abbreviated to “DPC”), and 0.591 parts by weight of cesium carbonate (0.2% by weight aqueous solution) as a catalyst. In a nitrogen atmosphere, the temperature of the heat medium of the reaction vessel was regulated to 150° C. to dissolve the starting materials while stirring the mixture according to need (about 15 minutes) in preparation for a first reaction step.

[0116]Subsequently, the internal pressure of the reaction vessel was reduced from ordinary pressure to 13.3 kPa, and the temperature of the heat medium of the reaction vessel was elevated to 190° C. over 1 hour, during which the phenol ...

example 2

[0120]The same procedure as in Example 1 was conducted, except that use was made of 35.1 parts by weight of ISB, 90.2 parts by weight of BHEPF, 10.6 parts by weight of diethylene glycol (hereinafter often abbreviated to “DEG”), 118.6 parts by weight of DPC, and 0.666 parts by weight of the aqueous cesium carbonate solution as a catalyst. Thus, a polycarbonate resin B was obtained. The polycarbonate resin B obtained had a composition composed of BHEPF / ISB / DEG=37.7 mol % / 44.0 mol % / 18.3 mol %. The properties of the polycarbonate resin B were determined. A transparent film was formed therefrom in the same manner as in Example 1, and the properties thereof were determined. The results thereof are shown in Table 1.

example 3

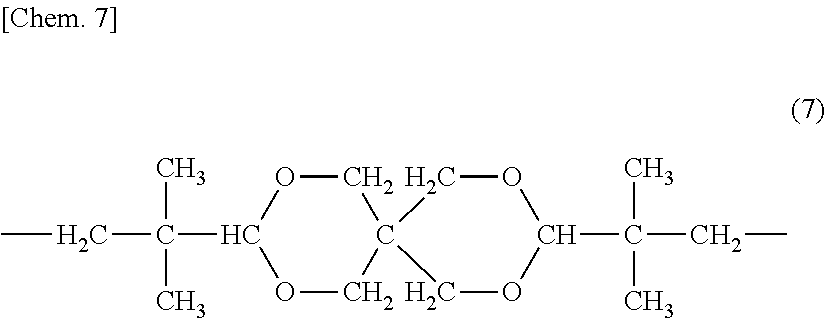

[0121]The same procedure as in Example 1 was conducted, except that use was made of 27.8 parts by weight of ISB, 82.1 parts by weight of BHEPF, 25.6 parts by weight of 1,4-CHDM, 120.8 parts by weight of DPC, and 0.679 parts by weight of the aqueous cesium carbonate solution as a catalyst. Thus, a polycarbonate resin C was obtained. The polycarbonate resin C obtained had a composition composed of BHEPF / ISB / 1,4-CHDM=33.7 mol % / 34.3 mol % / 32.0 mol %. The properties of the polycarbonate resin C were determined. A transparent film was formed therefrom in the same manner as in Example 1, and the properties thereof were determined. The results thereof are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass-transition temperature | aaaaa | aaaaa |

| birefringence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com