Process for Inoculating a Bioreactor with Cyanobacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Sequential Grow Up of Inoculum

[0057]The initial inoculation of the inoculum scale-up system is performed in the sterile laminar flow hood by transferring 100 mL of culture into the 1 L bottle in the scale-up system (using a sterile pipet). This culture is then diluted with sterile MBG11 media until there is approximately 600-900 mL in the bottle. All further transfers are performed according to inoculum scale-up system protocols (i.e. pressurization of culture bottle or media bottle and opening of valves without breaking the sterile envelope).

Transfer to 5 L Bottle

[0058]In the 1 L bottle, there will be approximately 900 mL of culture. When this volume reaches an ideal optical density at 750 nm (OD750) of 4.0 (or higher, provided the culture is not in stationary phase), it is to be transferred to the previously connected three 5 L bottles. Each 5 L bottle receives 300 mL of inoculum. The 5 L bottles are then topped with 2 L of MBG11, from the previously attached sterile media carboy....

example 2

Protecting Inoculum from Contamination

[0062]In previous work, the transfer of inoculum into 1 liter and 5 liter containers was done in a fume hood, which required extra time and space. The repeated need to use the fume hood represented a bottleneck in the process of growing up inoculum. Furthermore, more frequent manipulations increased the risk of contamination. One has to do work sterilely, and any time one opens up a flask there is always a risk of contamination.

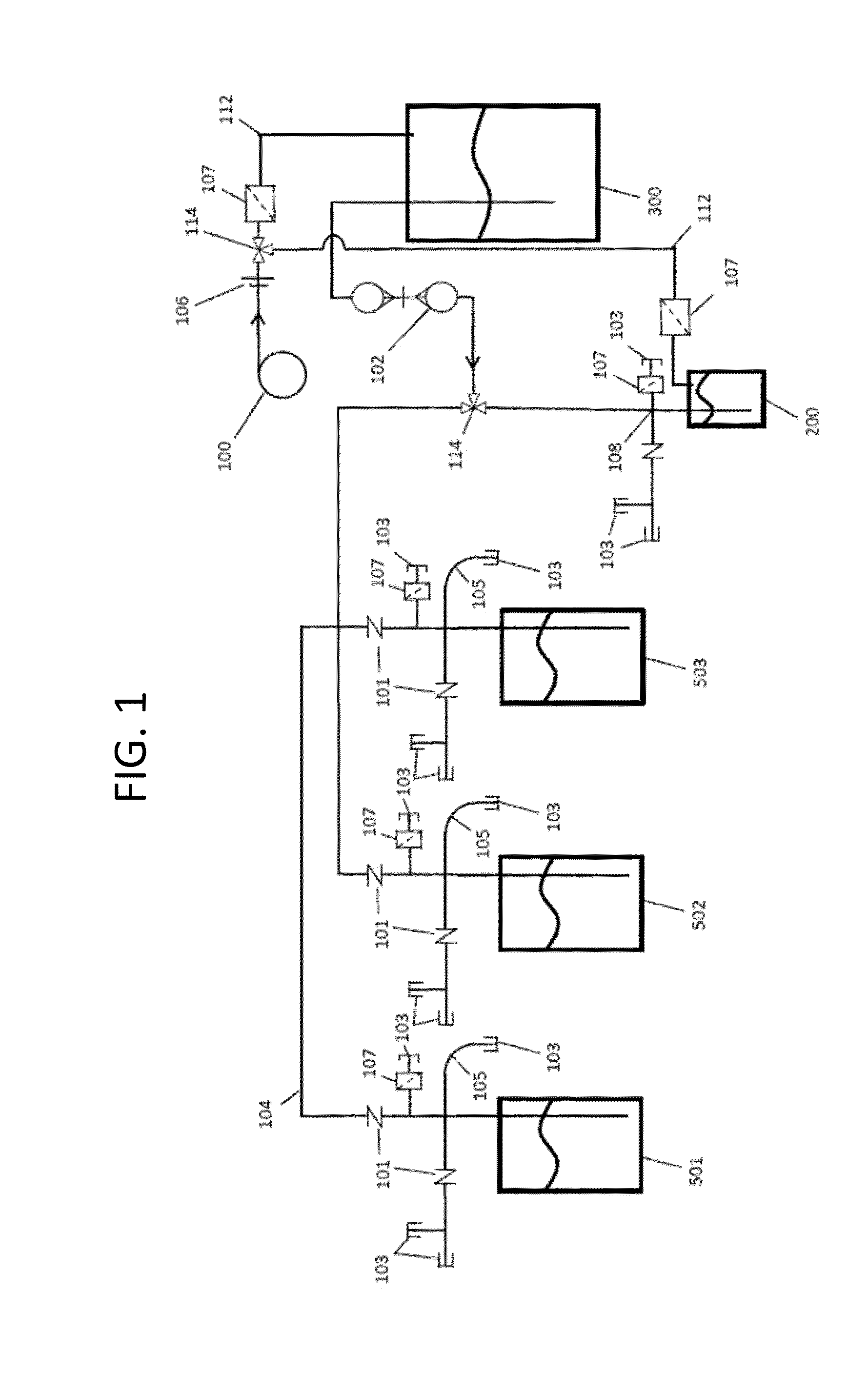

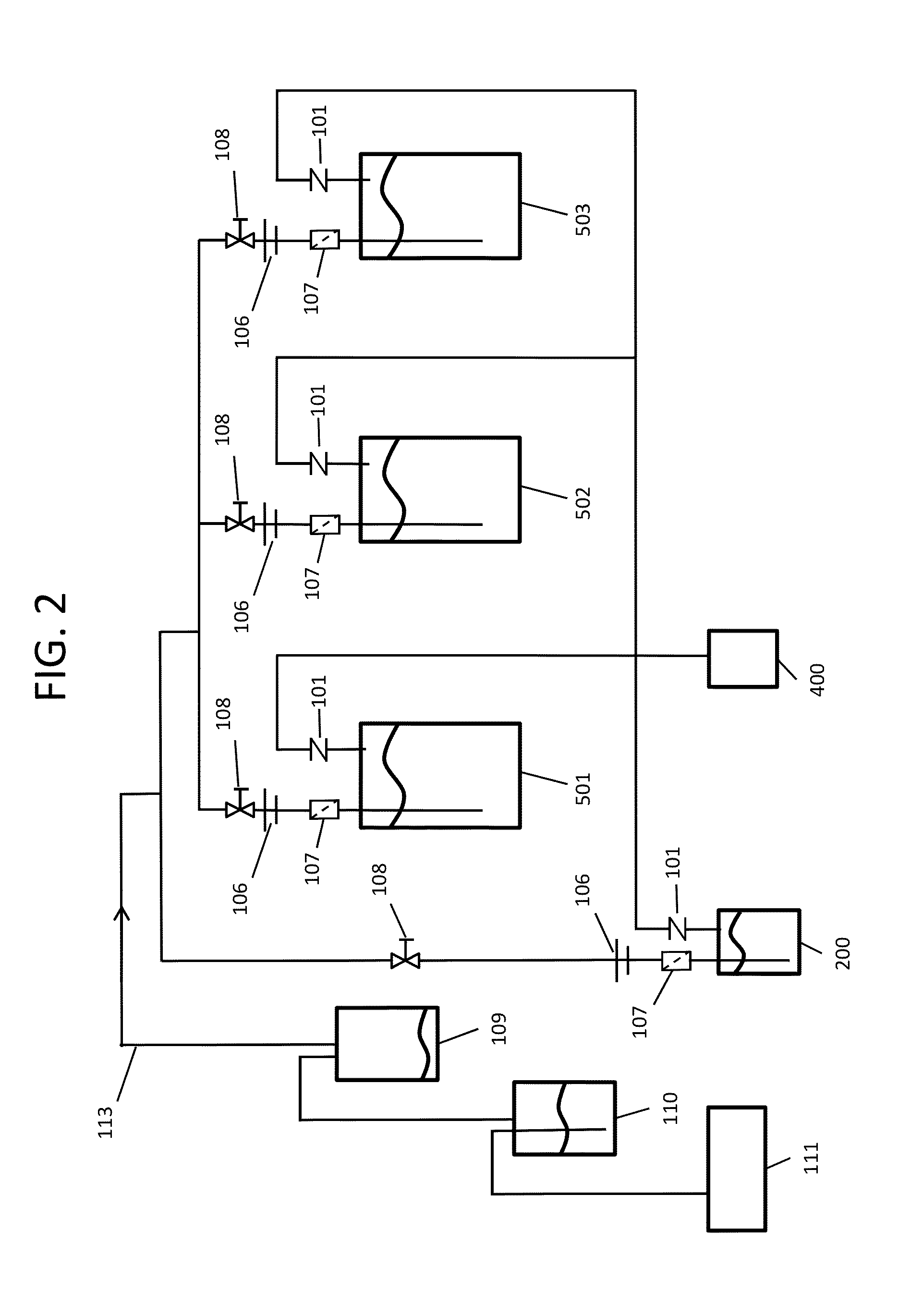

[0063]In the present embodiment, depicted schematically as a system in FIG. 1, the one liter bottle and the five liter bottles are autoclaved as an interconnected system. The 20 liter carboy is autoclaved separately, but then connected aseptically to system in the hood or by sterile tube-fused connections outside of the hood. There is a transfer of the initial inoculum, in the hood or by sterile tube-fusing, to the one liter container. All connections are made and removed in the hood, which can be mobile, or by remote ste...

example 3

Staged Inoculum Up to 4,500 Liter

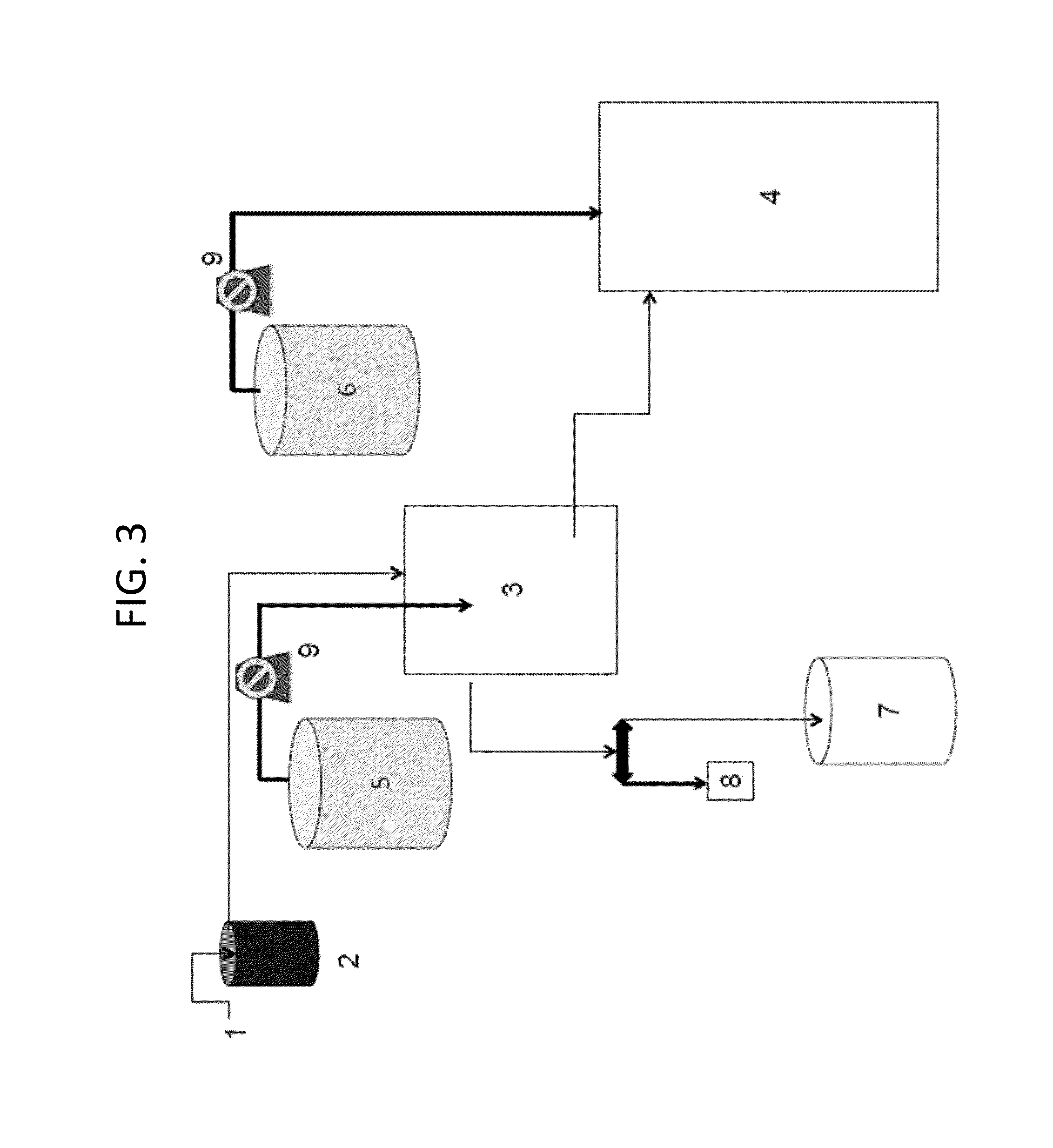

[0068]Using the procedure outline in Example 2, 900 mL of liquid was transferred sequentially to a 1 liter bottle. The 900 mL comprised 150 mL of culture and 750 mL of media and nutrients.

[0069]After obtaining an OD of 2.0, the 900 mL of culture was transferred via pumping according to Example 2 into two 5 liter bottles with 2 liters of media in each. When the OD within the 5 liter bottles reached 1.5, an another liter of media was added to each bottle. When the OD once again reached 1.5, an additional 2 liters of media was added to each 5 liter bottle, for a total volume of 4 liters in each bottle.

[0070]After obtaining an OD of 3.0, the 8 liters of culture was transferred via pumping according to Example 2 into 20 liters of natural salt water within an 80 liter bioreactor supported on a frame. Each time the OD reached 2.0, the volume was doubled until there were 80 liters in the reactor.

[0071]After obtaining an OD of 2.5 in the volume of 80 liters, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com