Liquefaction of Natural Gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

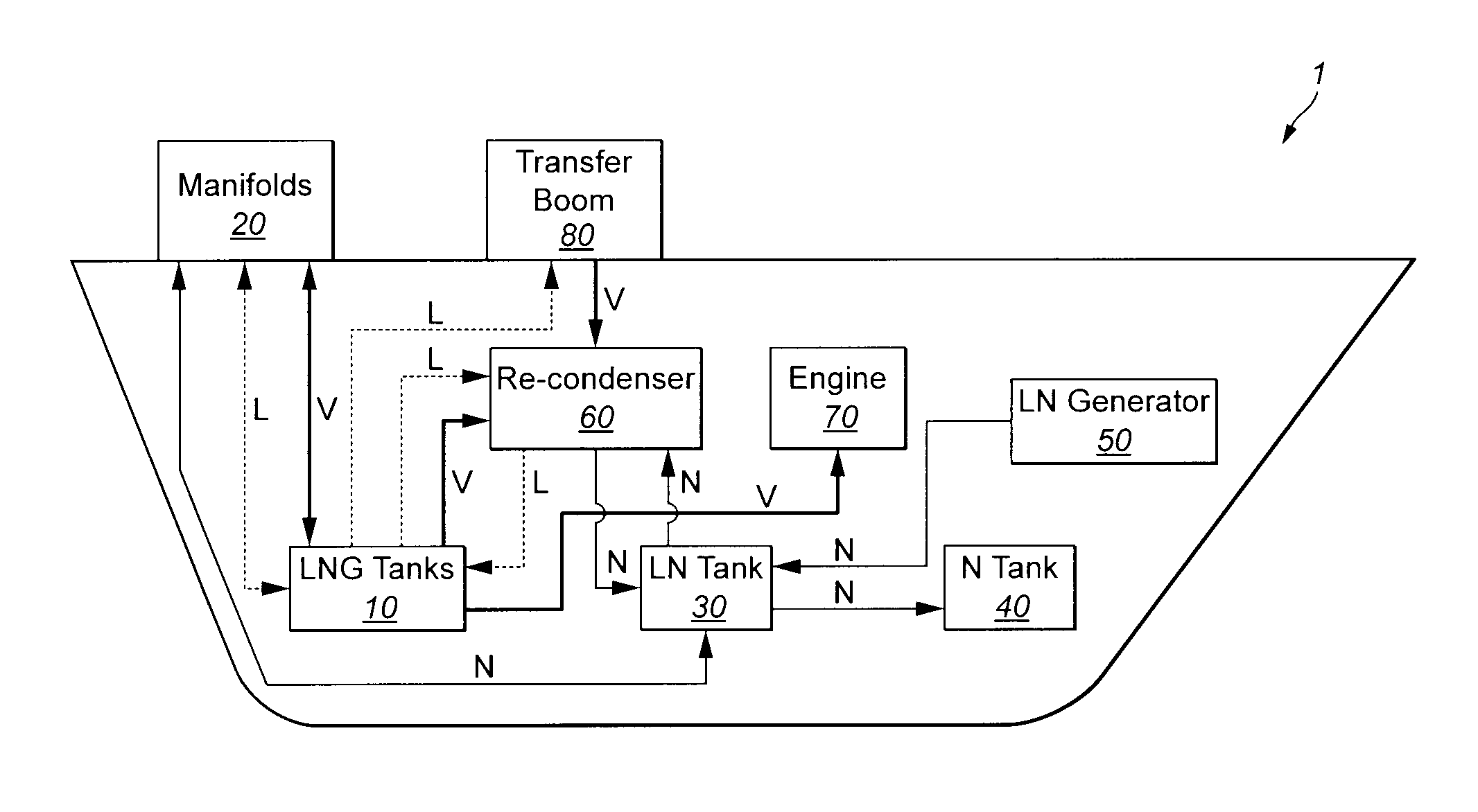

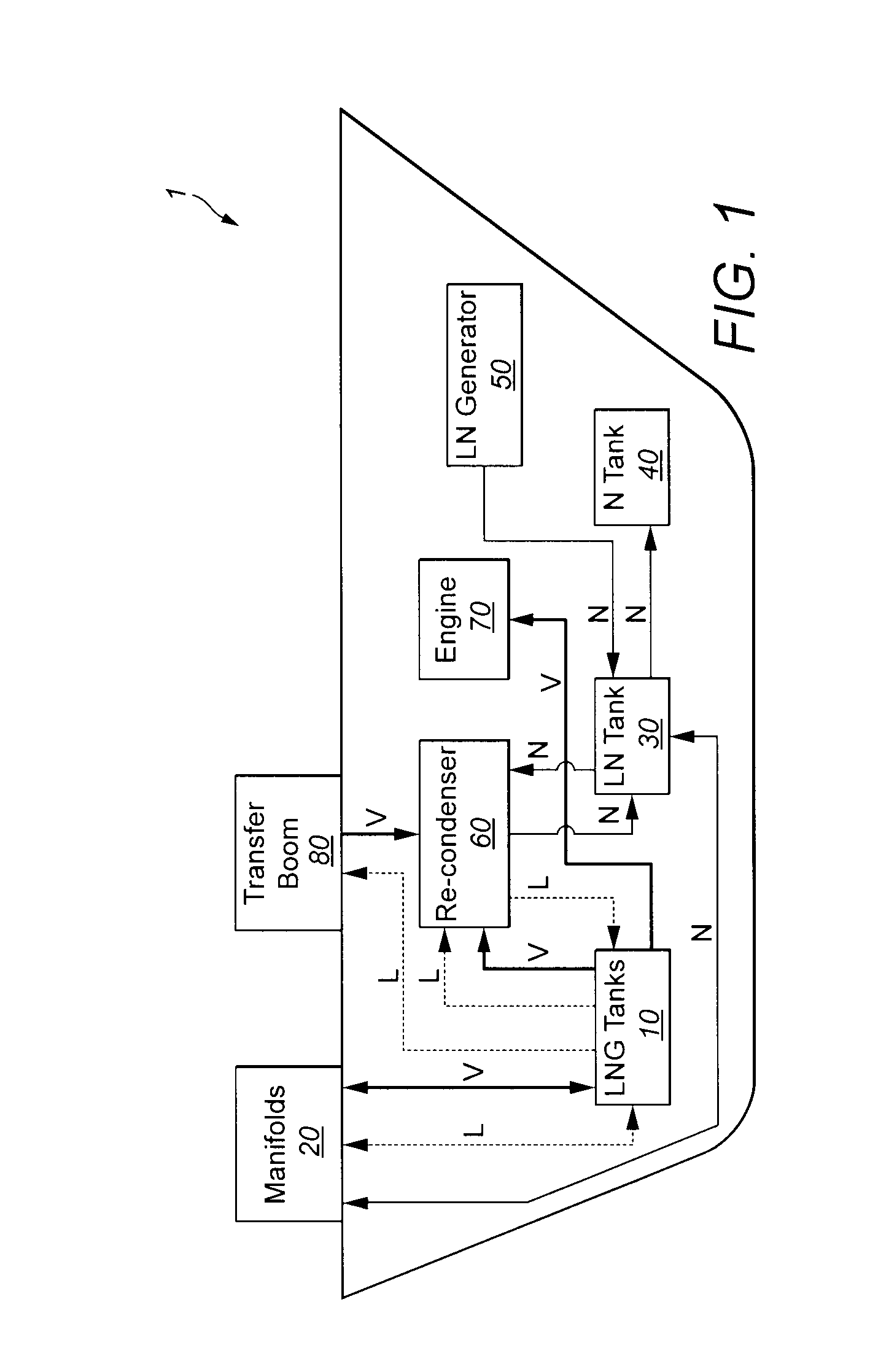

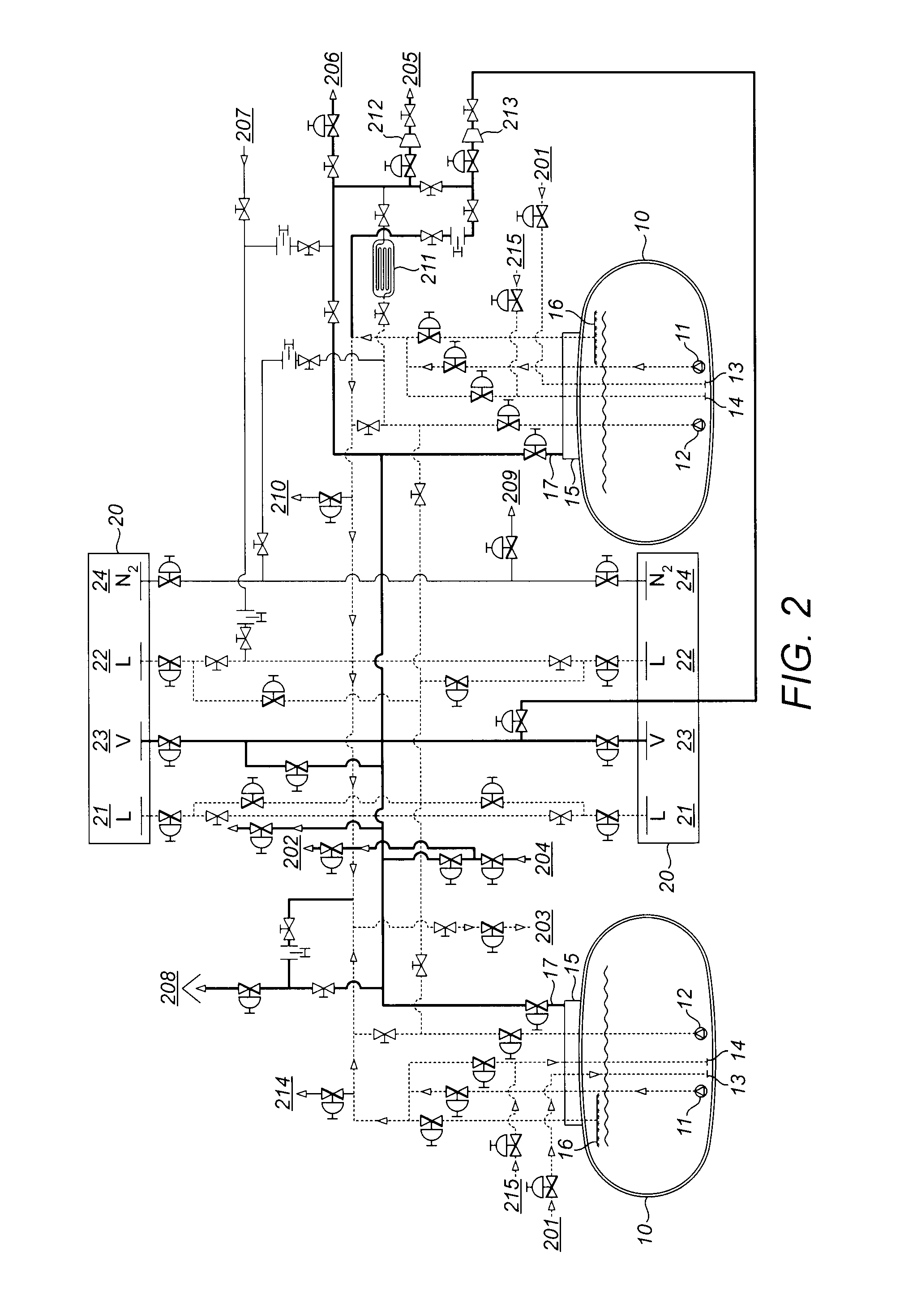

[0029]Referring to FIG. 1, a schematic diagram is provided showing the principle elements of a LNG handling system aboard a bunker vessel 1 for re-fuelling larger ships. The system comprises two LNG storage tanks 10, port and starboard manifolds 20, a liquid nitrogen tank 30, a gaseous nitrogen tank 40, a liquid nitrogen generator 50, a re-condenser unit 60, engines 70 and a flow boom 80. FIG. 1 illustrates functional connections between the various illustrated elements of the system for the transfer of LNG (indicated as “L”, dotted lines), natural gas vapour (indicated as “V”, thick lines) and nitrogen (both liquid and gaseous indicated as “N”, thin lines).

[0030]The port and starboard manifolds 20 are arranged to allow transfer of LNG, natural gas vapour, and nitrogen between the bunker vessel and an on-shore facility. LNG received from the port and starboard manifolds is stored in the storage tanks 10. In this embodiment, the storage tanks are pressurised, C-class, storage tanks w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com