Method of Myceliating Coffee

a technology of myceliation and coffee, applied in the field of methods, can solve the problems of time-consuming fruiting of mushrooms, long time-consuming medicinal or gourmet mushrooms, etc., and achieve the effects of enhancing the neuroprotective effect of products, enhancing production efficiency, and improving myceliation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

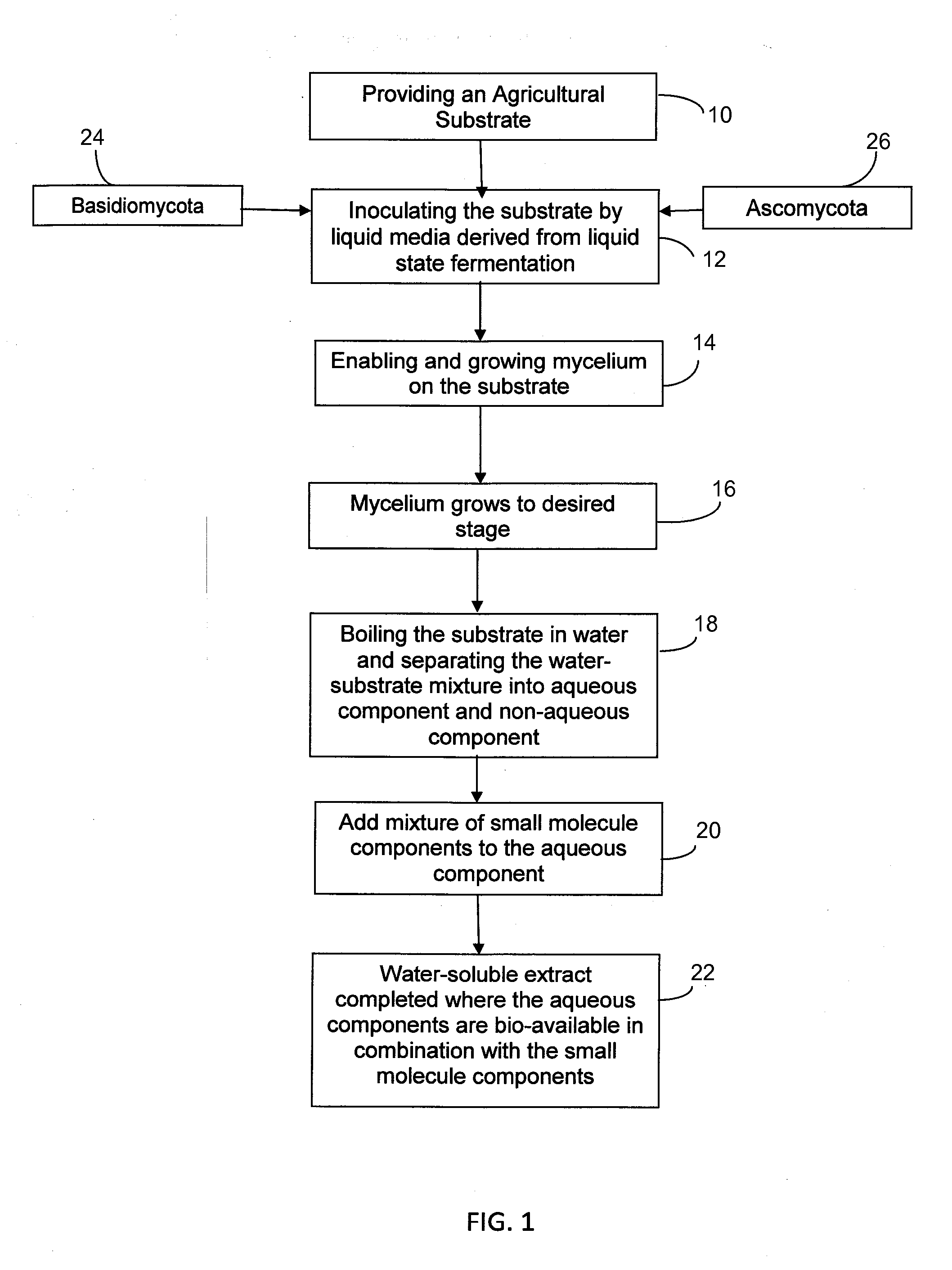

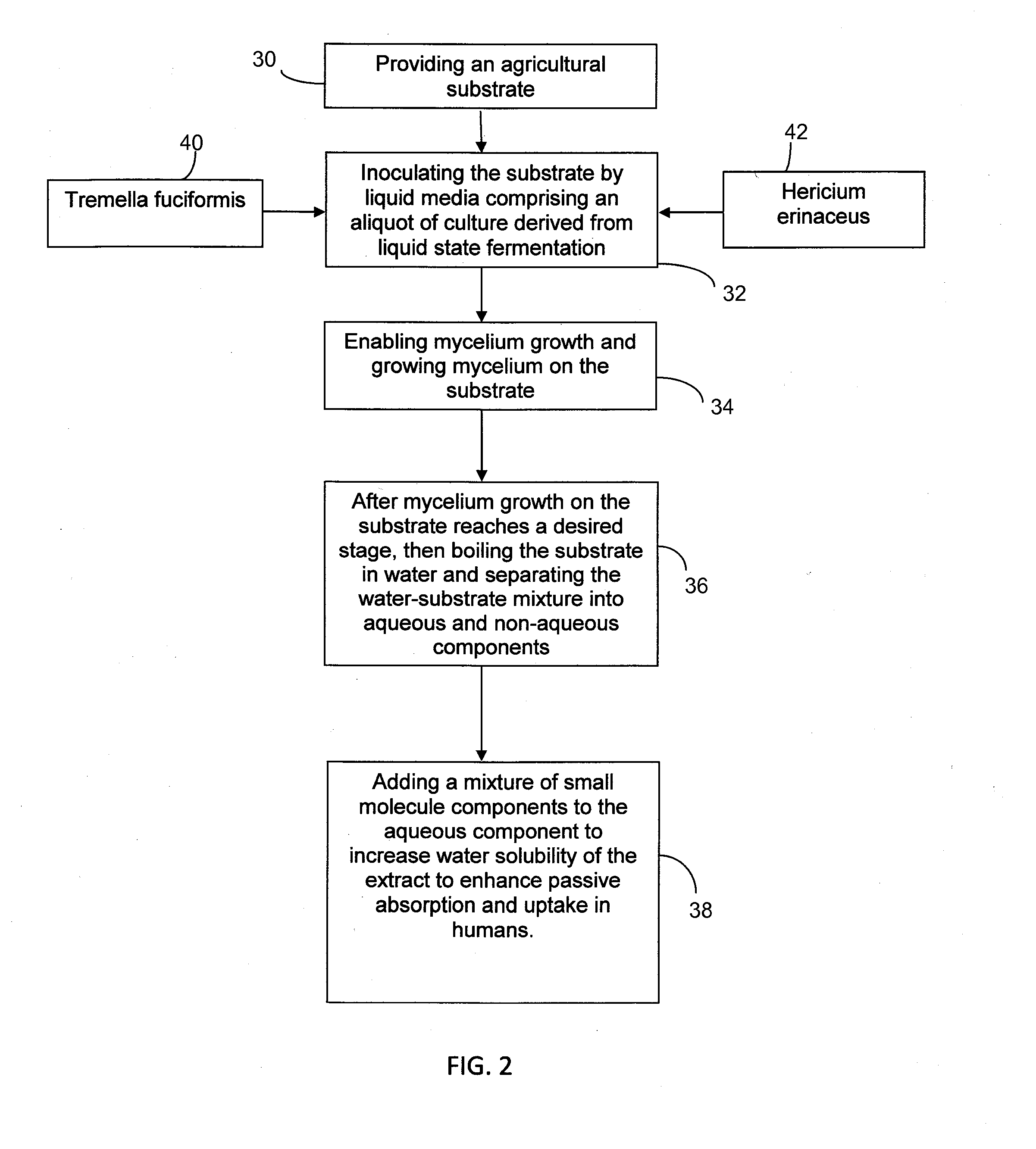

Method used

Image

Examples

process example # 1

PROCESS EXAMPLE #1

[0056]Using specific and pure strains of fungi obtained from referenced collections are manipulated in sterile environments at 68 degrees F. to 90 degrees F., in 1 gal to 10 gal plastic bags, 1 qt to 1 gal glass jar, or on 10 cm to 15 cm Petri plates, using undefined, organic fruit and vegetable-based media with 1.5% agar (w / v), in order to monitor and ensure the general vigor and health of strains. Mycelial samples are grown in a gentle, ambient sterile airflow for 2 to 4 weeks, then excised from Petri plates and subsequently used for inoculation into liquid-state fermentation employing a similar undefined fruit and vegetable-based media (but with no agar), using ambient air, in 1 qt to 1 gal glass jars, with agitated or unagitated cultures in ambient air in stainless steel tanks which have been designed for commercial beer brewing and / or fermentation. There is a subtle difference between unagitated and agitated liquid-state fermentation. Unagitated liquid-state f...

process example # 2

PROCESS EXAMPLE #2

[0057]In using unagitated liquid state fermentation, after commanding the liquid-state medium for a growth period of 2 to 4 weeks, cultures form a floating mass of hyphae, which are gently blended with a sharp, sterile cutting device prior to being used for inoculation. Gentle blending is achieved by mixing or low homogenization in a commercial blender in short bursts at slow speeds. Aliquots of blended liquid-state culture are used to inoculate sterilized unprocessed fruits and or vegetables, cereal grains, and / or culinary seed, or pasteurized culinary spice, medicinal herbs, natural flavorings, tea mixes, green vanilla beans, green cacao beans, and / or green coffee beans.

SUBSTRATE TREATMENT

[0058]Agricultural substrate requiring sterilization such as unprocessed fruits and / or vegetables, cereal grains or culinary seed, is modified using heat treatment by pressure cooking for 90 minutes at 15 lb / in2 and then cooled to room temperature prior to inoculation by liquid-...

process example # 3

PROCESS EXAMPLE #3

[0059]In one embodiment: small batch liquid-state and solid-state fermentation; pure cultures of fungi are grown semi-aerobically and inoculated into 1 qt to 1 gal glass jars, or into 1 gal to 5 gal autoclavable plastic bags containing properly prepared grain or similar agricultural materials such as fruit, vegetables, herbs, spices, teas, green vanilla beans, green cacao beans, and / or green coffee beans; then, depending upon strain of fungi and substrate, grown at 70 degrees F. to 90 degrees F. Cultures in jars or bags are gently mixed every few days until they command the substrate whereby eventually becoming somewhat resistant to mixing or shaking, usually 2 to 4 weeks depending upon strain, and are intended for small-scale production of functional food products sold in a tempeh form. The myceliated green vanilla beans are cooked or baked; the myceliated green cacao beans are bake or toasted; and the myceliated green coffee beans are toasted or roasted. Myceliat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com