Viscosity index improver, method for producing same, and oil composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

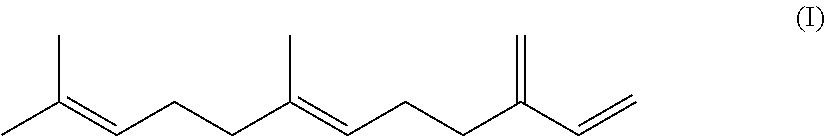

[0101]A pressure reaction vessel previously purged with nitrogen and then dried was charged with 62.4 kg of cyclohexane as a solvent and 51.0 g of sec-butyl lithium (in the form of a 10.5% by mass cyclohexane solution) as an anionic polymerization initiator. The contents of the reaction vessel were heated to 50° C., and then 2.34 kg of styrene (1) was added thereto, followed by polymerizing the contents of the reaction vessel for 1 h. Successively, 10.9 kg of β-farnesene was added to the reaction vessel, followed by polymerizing the contents of the reaction vessel for 2 h. Furthermore, 2.34 kg of styrene (2) was added to the reaction vessel, followed by polymerizing the contents of the reaction vessel for 1 h, thereby obtaining a reaction solution containing a polystyrene-poly(β-farnesene)-polystyrene triblock copolymer. Added into the reaction solution was palladium carbon (amount of palladium supported: 5% by mass) as a hydrogenation catalyst which was used in an amount of 5% by m...

example 2

[0103]A pressure reaction vessel previously purged with nitrogen and then dried was charged with 62.4 kg of cyclohexane as a solvent and 40.6 g of sec-butyl lithium (in the form of a 10.5% by mass cyclohexane solution) as an anionic polymerization initiator. The contents of the reaction vessel were heated to 50° C., and then 13.0 kg of β-farnesene was added thereto, followed by polymerizing the contents of the reaction vessel for 2 h. Successively, 2.59 kg of styrene was added to the reaction vessel, followed by polymerizing the contents of the reaction vessel for 1 h, thereby obtaining a reaction solution containing a poly(β-farnesene)-polystyrene diblock copolymer. Added into the reaction solution was palladium carbon (amount of palladium supported: 5% by mass) as a hydrogenation catalyst which was used in an amount of 5% by mass on the basis of the block copolymer, and the block copolymer was subjected to hydrogenation reaction under a hydrogen pressure of 2 MPa at a temperature ...

example 3

[0105]The same procedure as in Example 2 was repeated except that the respective components were formulated as shown in Table 1, thereby obtaining a hydrogenated block copolymer (A3) and an oil composition and subjecting the resulting products to the above evaluation. The results are shown in Tables 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com