Systems and methods for implementing digital vapor phase patterning using variable data digital lithographic printing techniques

a digital lithographic printing and variable data technology, applied in the direction of railway signalling, transportation and packaging, nuclear engineering, etc., can solve the problems of metals onto the substrate surface, inability to accurately and positively jet inkjet process, and complex number of steps, so as to increase the alignment fidelity of images transferred, reduce alignment errors, and facilitate the effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]U.S. Patent Application Publication No. 2012 / 0103212 A1 (the 212 Publication) published May 3, 2012 and based on U.S. patent application Ser. No. 13 / 095,714, which is commonly assigned and the disclosure of which is incorporated by reference herein in its entirety, proposes systems and methods for providing variable data lithographic and offset lithographic printing or image receiving medium marking. The systems and methods disclosed in the 212 Publication are directed to improvements on various aspects of previously-attempted variable data digital imaging lithographic marking concepts based on variable patterning of dampening solutions to achieve effective truly variable digital data lithographic image forming.

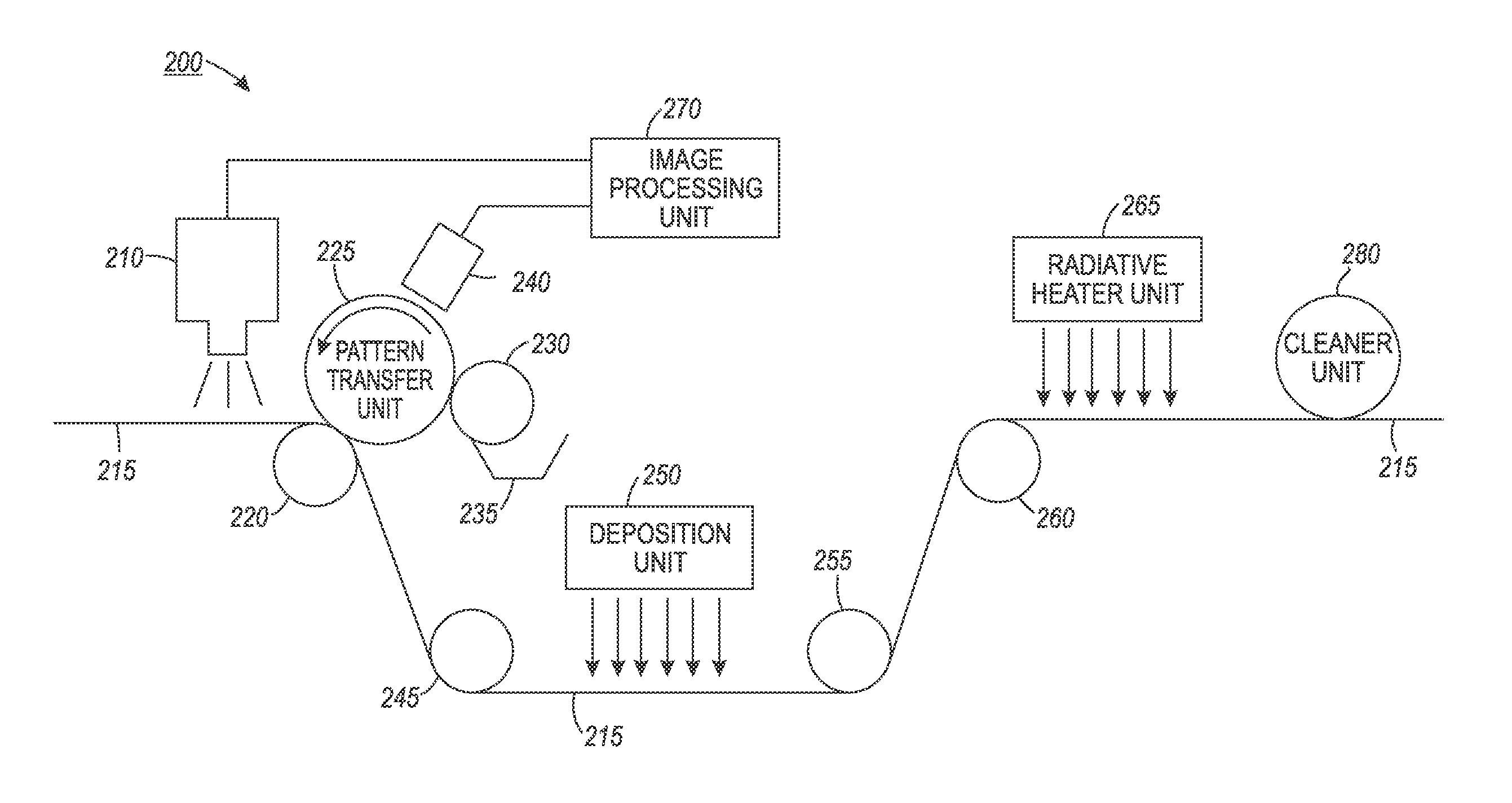

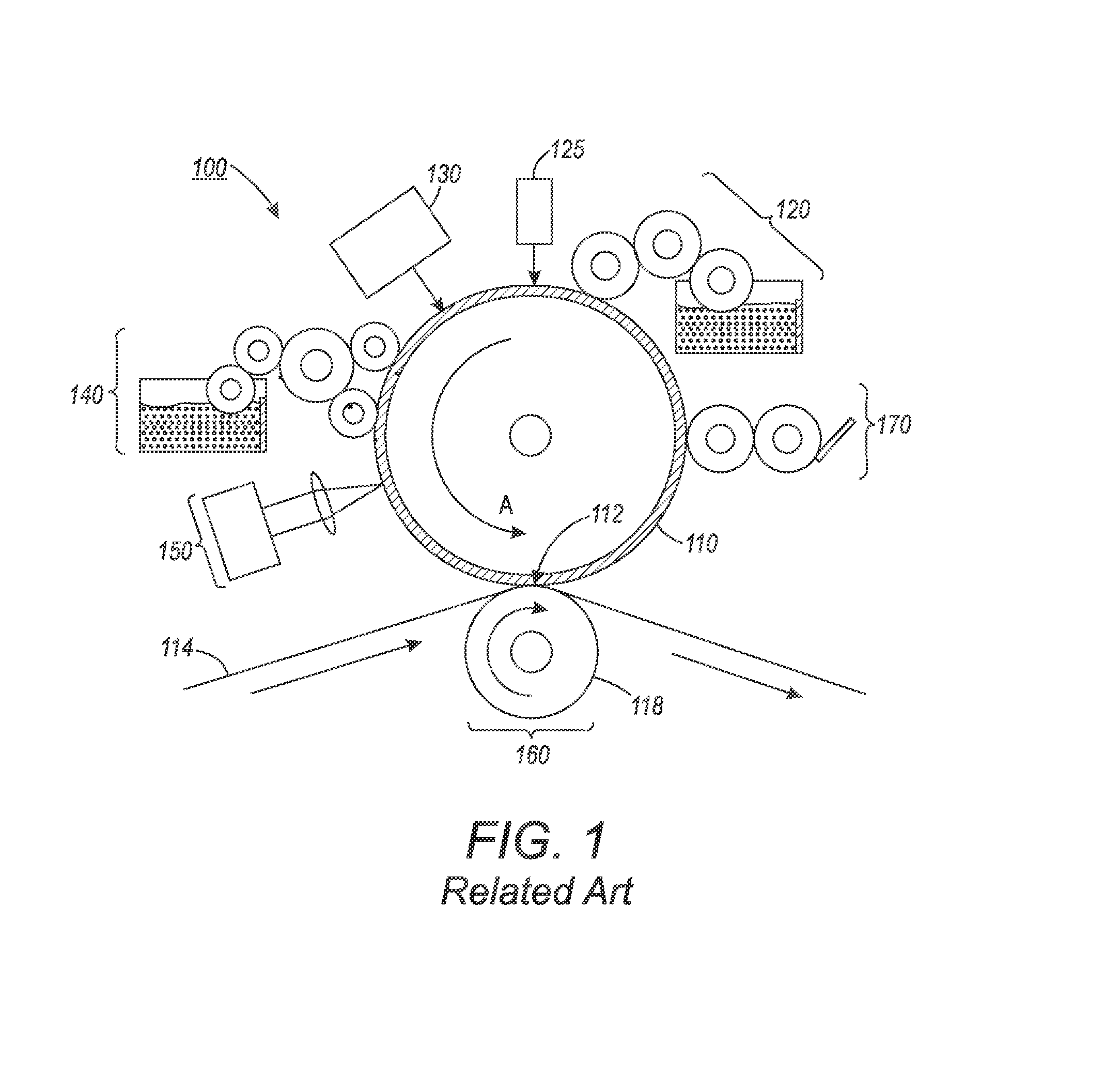

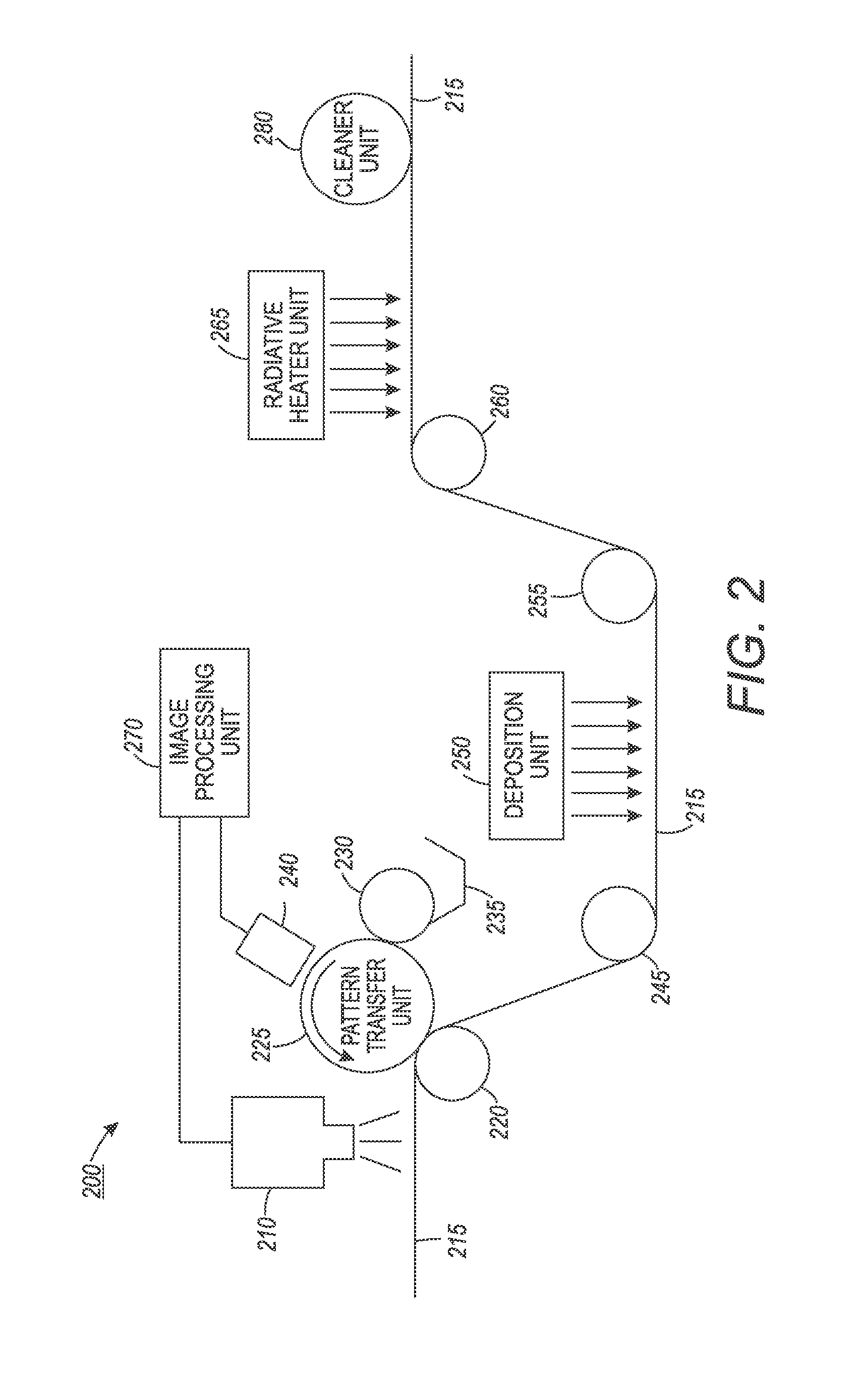

[0013]The 212 Publication describes, in requisite detail, an exemplary variable data lithography system 100 such as that shown, for example, in FIG. 1. A general description of the exemplary system 100 shown in FIG. 1 is provided here. Additional details regarding indiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Material properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com