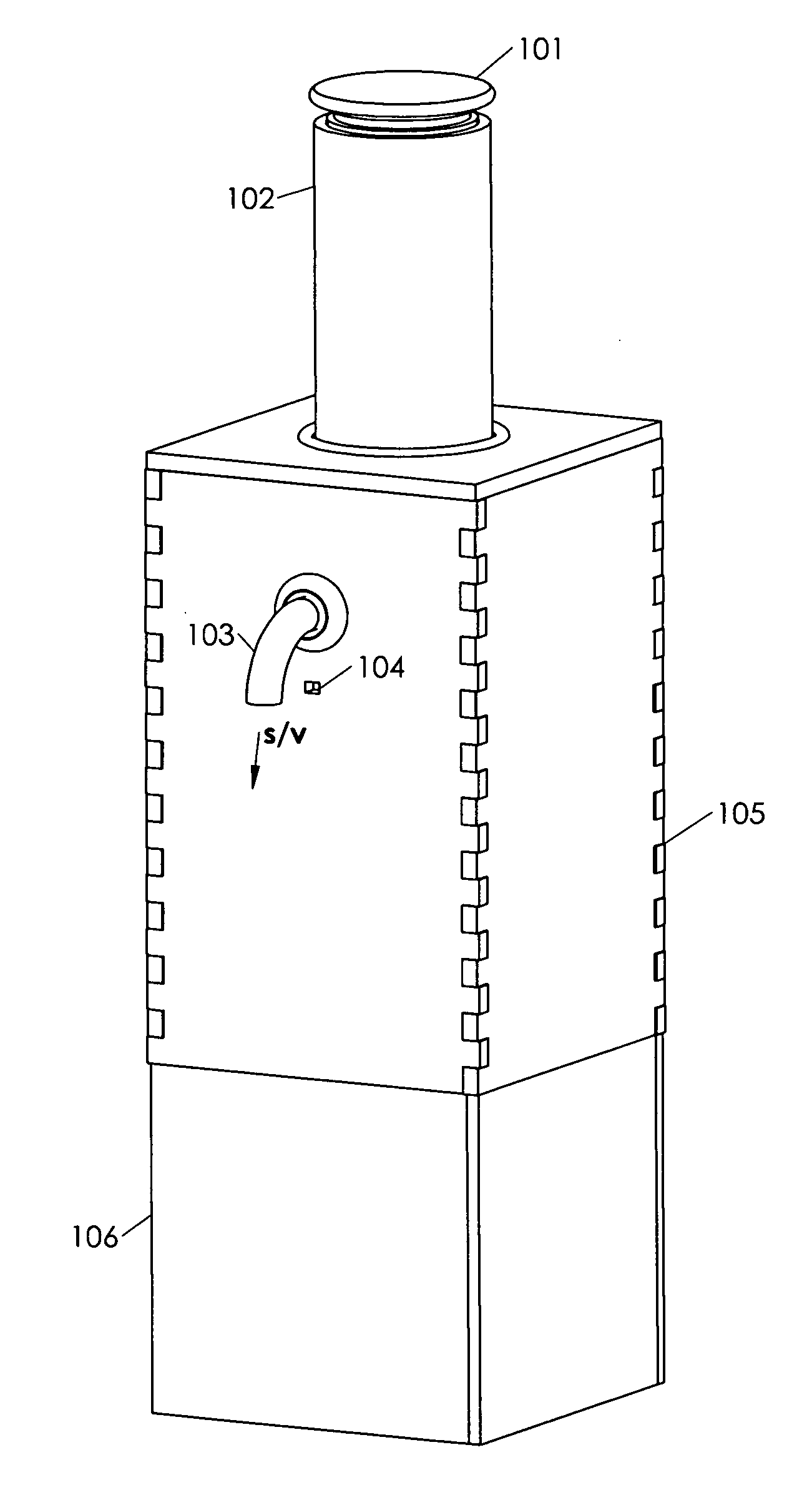

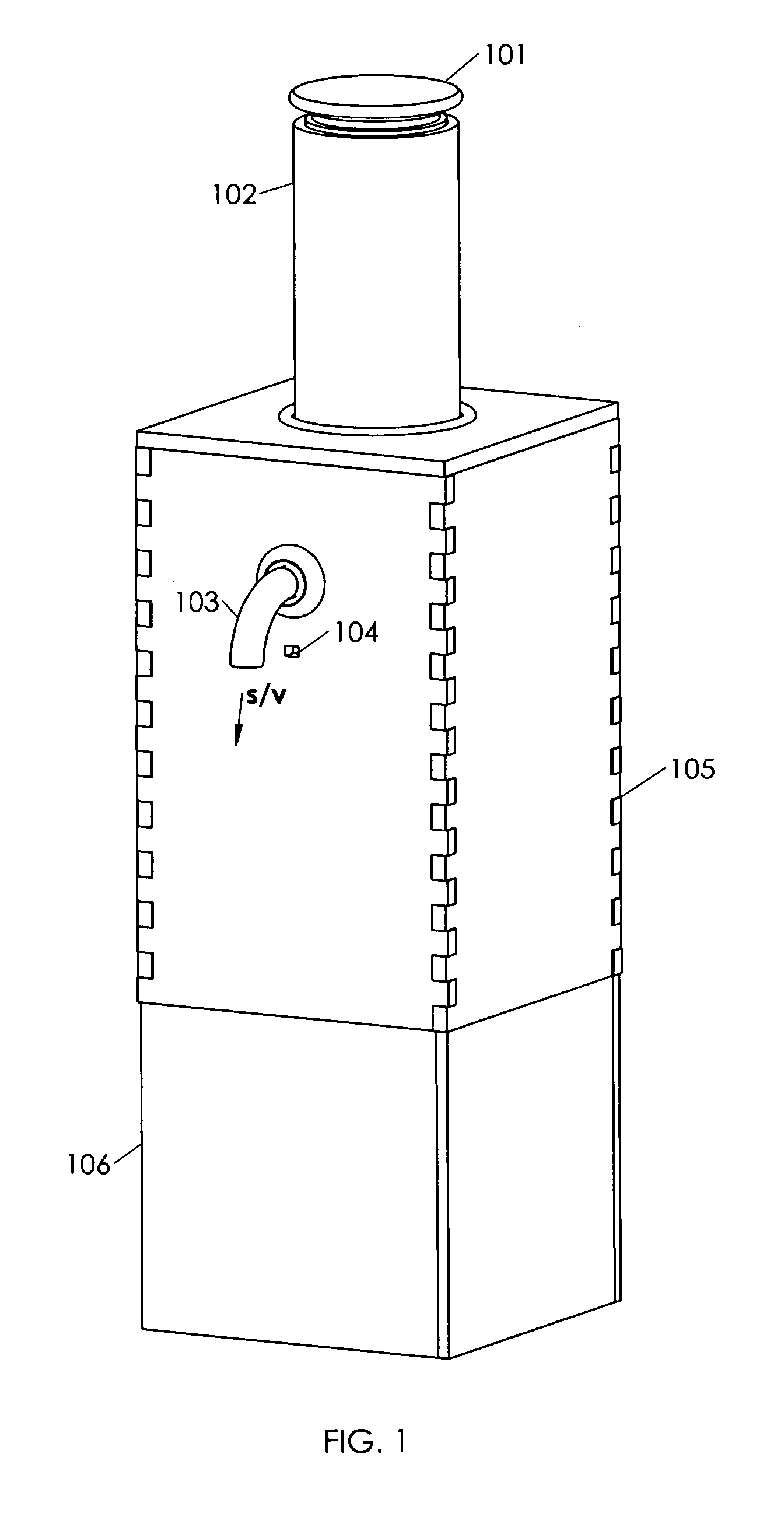

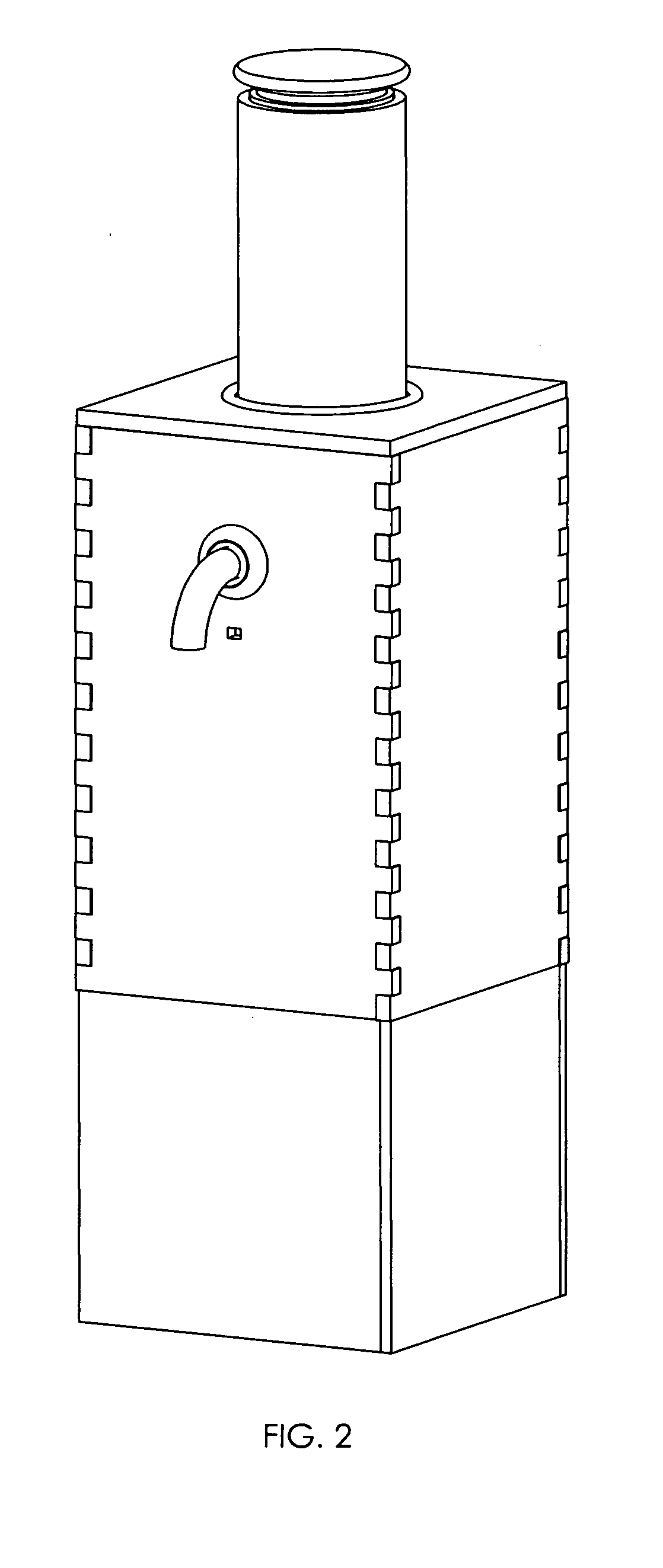

Smoke and/or Vapor Ignition, Cooling and Dispensing Device

a technology of vapor ignition and smoke, which is applied in the field of therapeutic smoking and/or vaporizing devices, can solve the problems of inability to portability external active cooling, limited use time, and active smoke cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009]The preferred embodiment described here begins by the user placing the Material to be Combusted and / or Vaporized into the Bowl (FIG. 7). Next, a Plenum Chamber (FIG. 10) is placed over the Bowl (FIG. 7) creating an air tight chamber to be pressurized, while the Bowl (FIG. 7) provides a passage for any positive pressure of air, liquid, or gas to pass through. After filling the Bowl (FIG. 7) with the desired material and creating an air-tight seal by placing the Plenum Chamber (FIG. 10) in its position, power is then provided to the Heating Element (FIG. 8) by the user activating a switch or sensor switch. The Heating Element (FIG. 8) then reaches temperatures in sufficiency to cause combustion, and / or vaporization while coming into contact and / or near proximity with the Material to Combusted and / or Vaporized. In a preferred embodiment, this occurs simultaneous to the Air Pump (FIG. 29) providing a supply of air to the Plenum Chamber (FIG. 10) via a Length of Tubing as electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com