System and Method for Renewable Fuel Using Sealed Reaction Chambers

a technology of reaction chamber and renewable fuel, which is applied in the direction of biofuels, chemistry apparatus and processes, and combustible gas coke oven heating. it can solve the problems of difficult to achieve uniform pressure and temperature, difficult to further process to make renewable fuel, and complex process. it achieves the effect of improving biomass processing uniformity and increasing biomass production rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Cartridge Embodiments

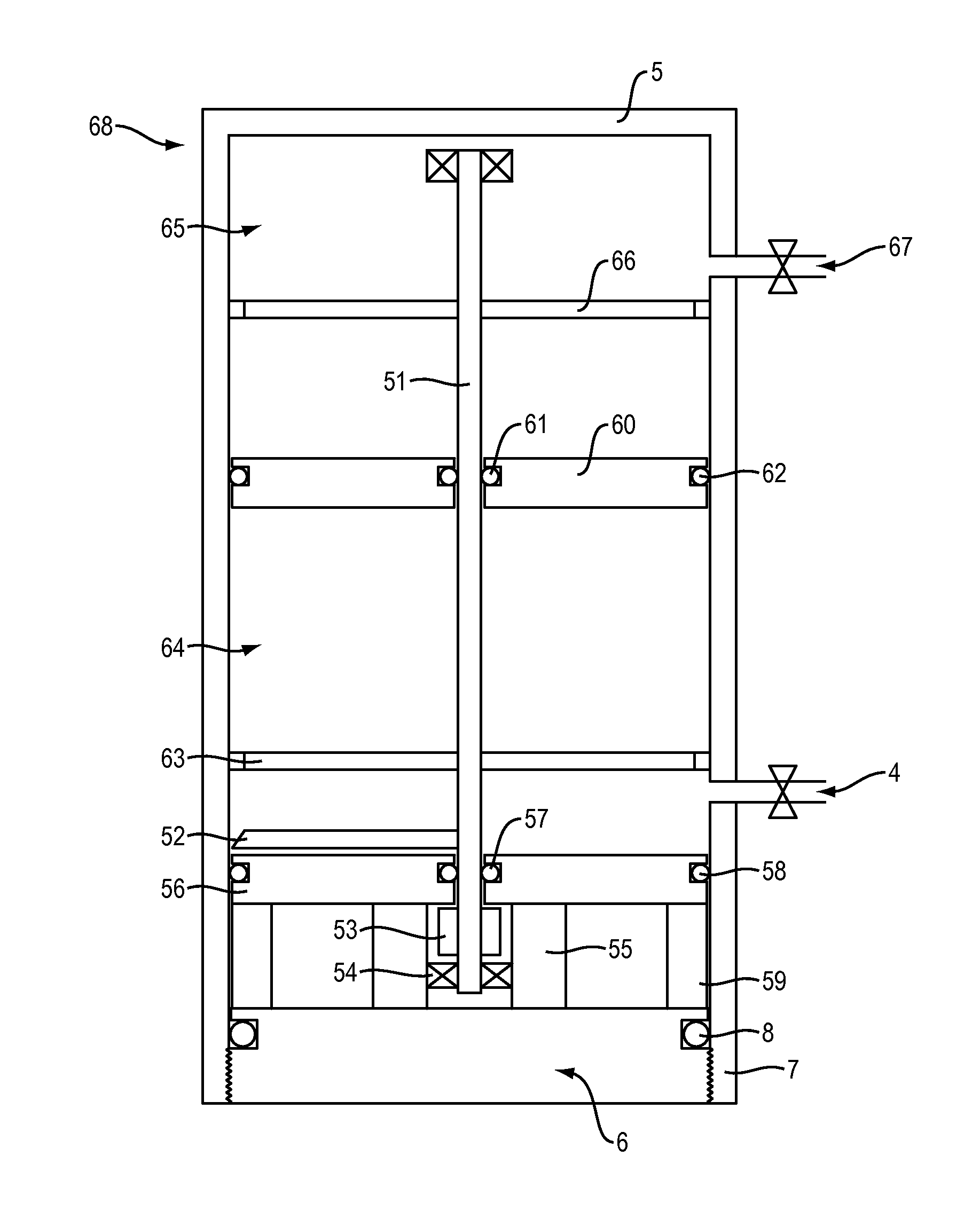

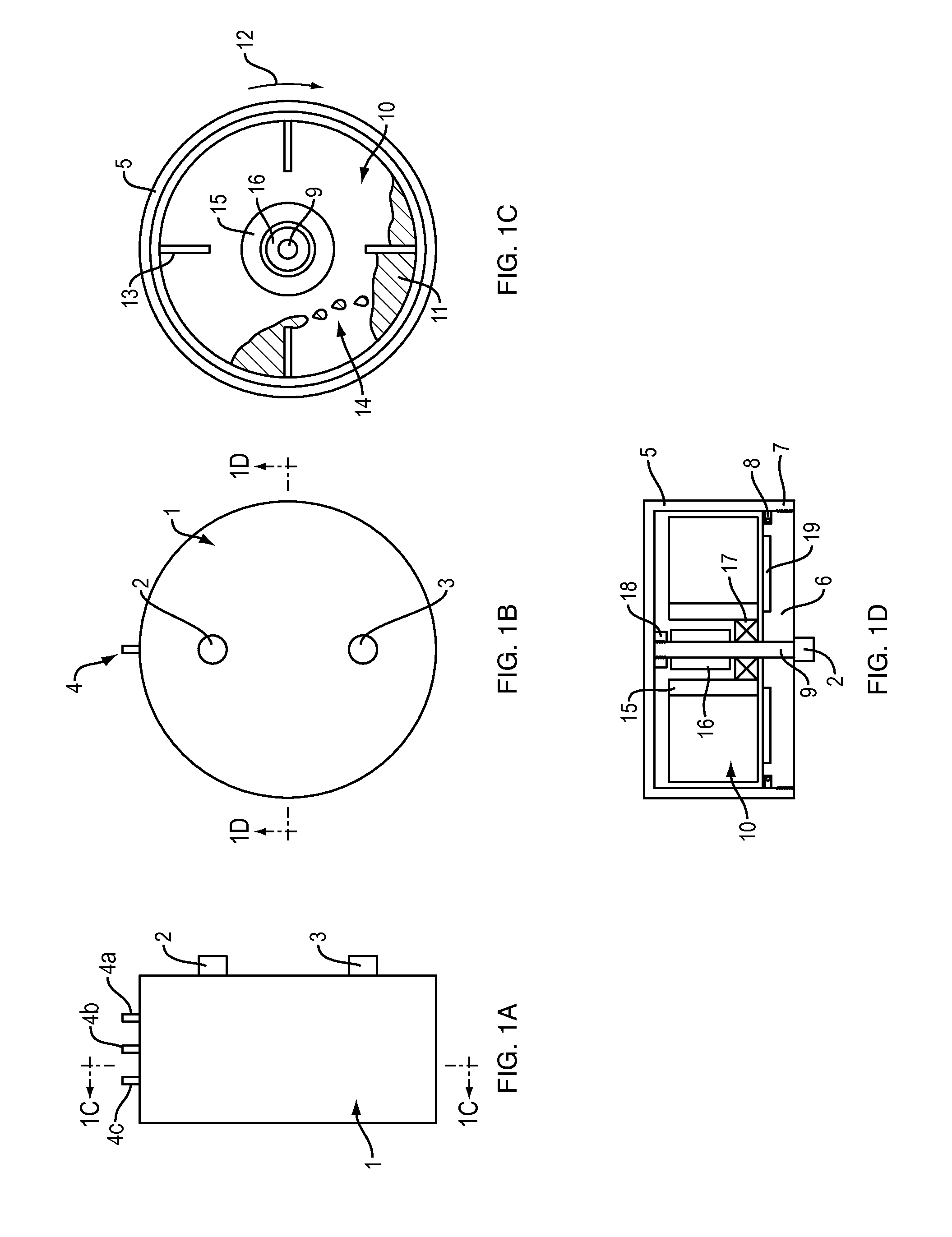

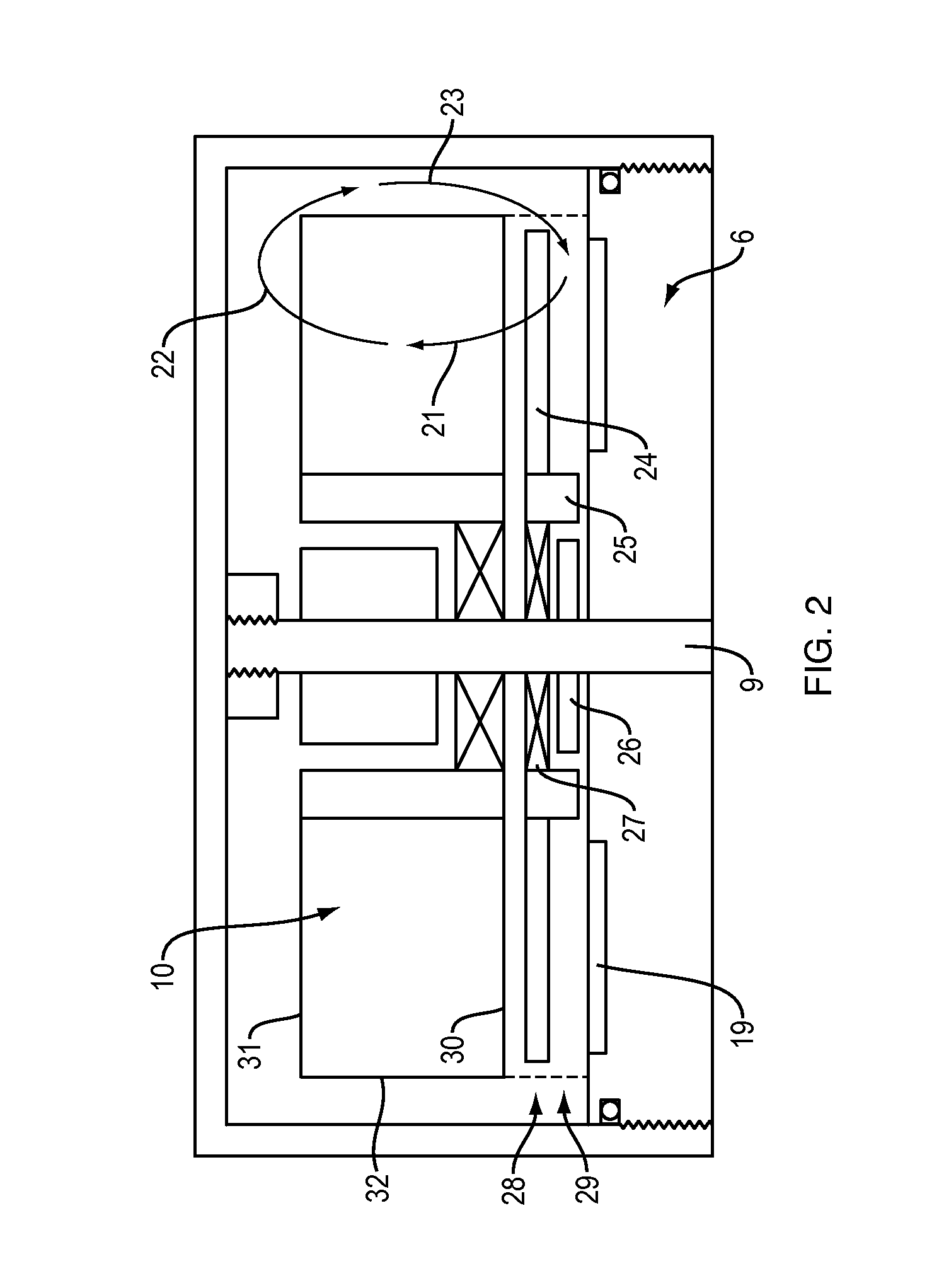

[0040]In one example embodiment, cartridges in accordance with various embodiments of the present invention may be utilized in the processing of solid biomass and the extraction of volatile components from the biomass in a supercritical fluid environment. There are a number of potential configurations for cartridges in accordance with the principles of the present invention. FIGS. 1A-1D and 2 illustrate an exemplary drum rotor cartridge, and FIG. 4 illustrates an exemplary mixing cartridge, but it should be understood that any number of cartridge configurations may be practicable.

[0041]FIGS. 1A through 1D provide respectively, a side view, an end view and two cross-sectional views of an embodiment of the present invention. FIG. 1A provides a side view of a drum rotor cartridge in accordance with an embodiment of the present invention. The side view of FIG. 1A shows a drum rotor cartridge 1, with various ports that may be useful during feedstock processing....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com