Magnetic structures for low leakage inductance and very high efficiency

a magnetic structure and leakage inductance technology, applied in the field of mechanical construction, can solve the problems of limited copper thickness, inability to offer a significant reduction of the total footprint to allow a reduction of the stray inductance, etc., to achieve the effect of improving the magnetic core configuration and winding arrangement, reducing the leakage inductance, and improving the utilization of copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

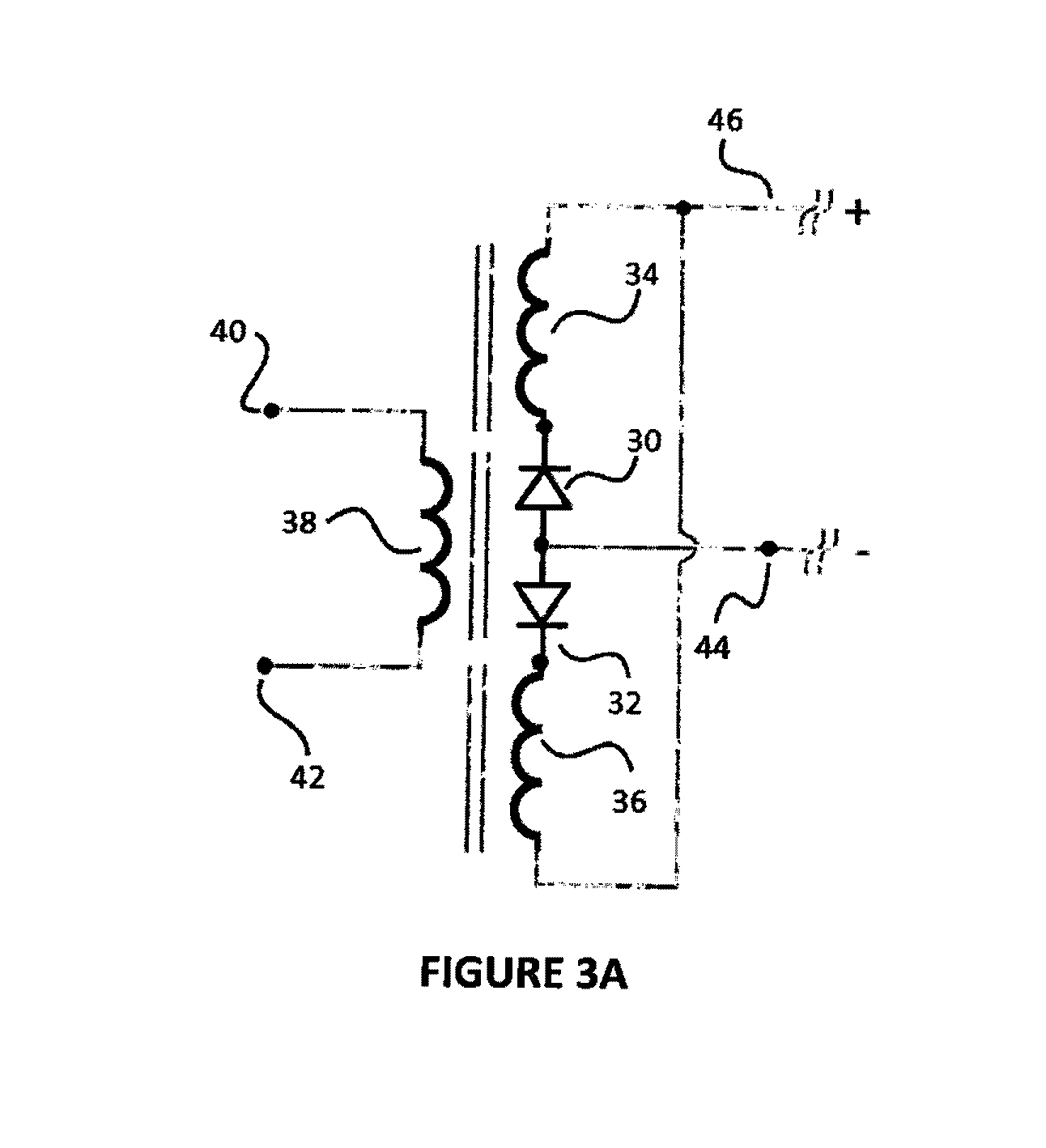

[0039]Presented in FIG. 3A is presented a center tap transformer structure having a primary winding 38, and two identical secondary windings 34 and 36. In the secondary side, there are two rectifier means, 30 and 32. The secondary rectifier means can be schottky diodes, synchronous rectifier using silicon power mosfets, GANs or other technologies. There is a positive output 46, and a negative output 44. Typically, the negative output it might be connected to the output ground. In the primary, an AC signal is applied to the primary winding between 40 and 42, which can be generated, by a full bridge configuration, half bridge or other topologies. In one of the polarities generated by the signal applied to the primary winding 38, one of the rectifiers means conducts and when the polarity changes the other rectifier means will conduct. Because only one of the secondary winding is conducting current during each polarity the copper in the secondary is not fully utilized. This is one of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| magnetic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com