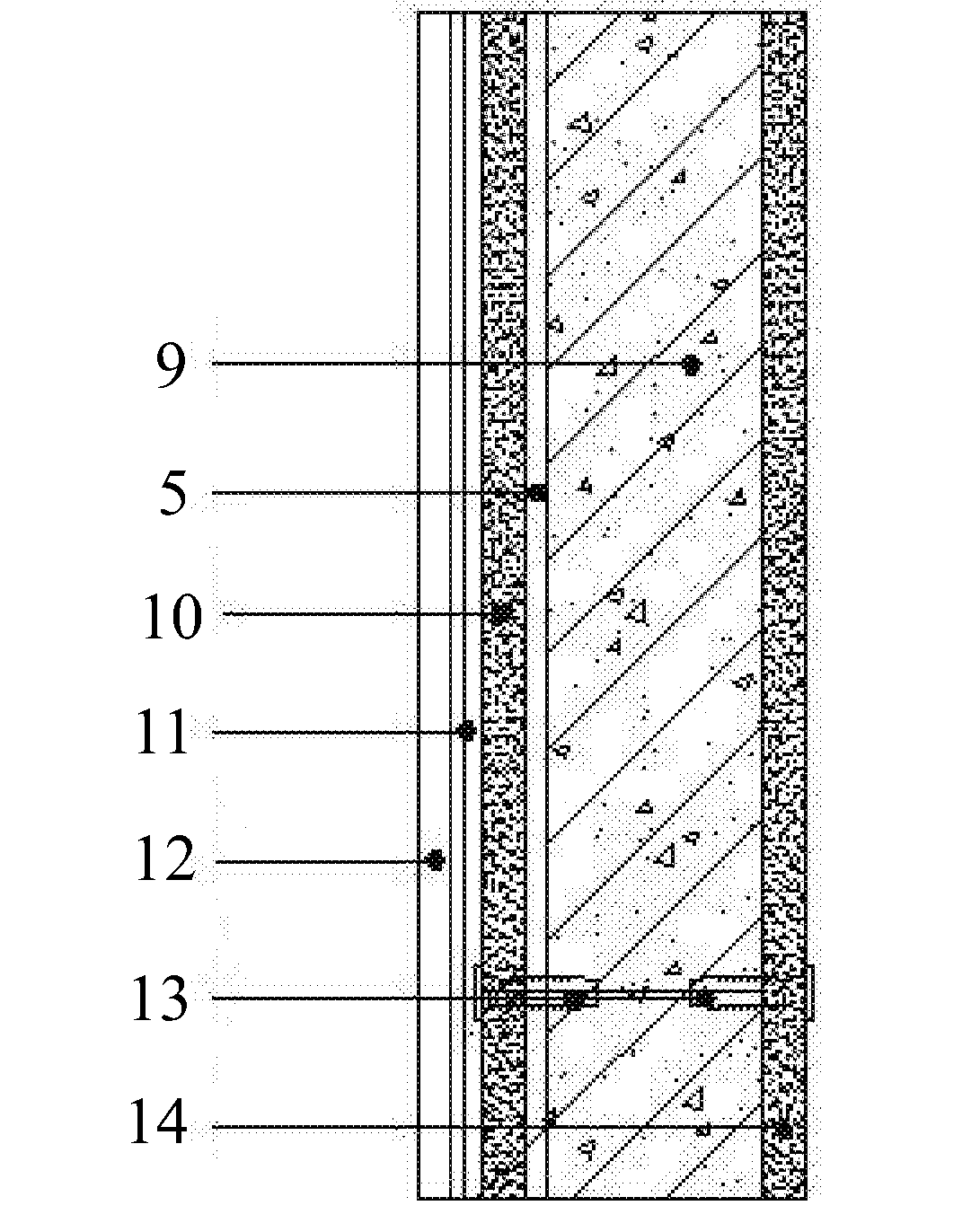

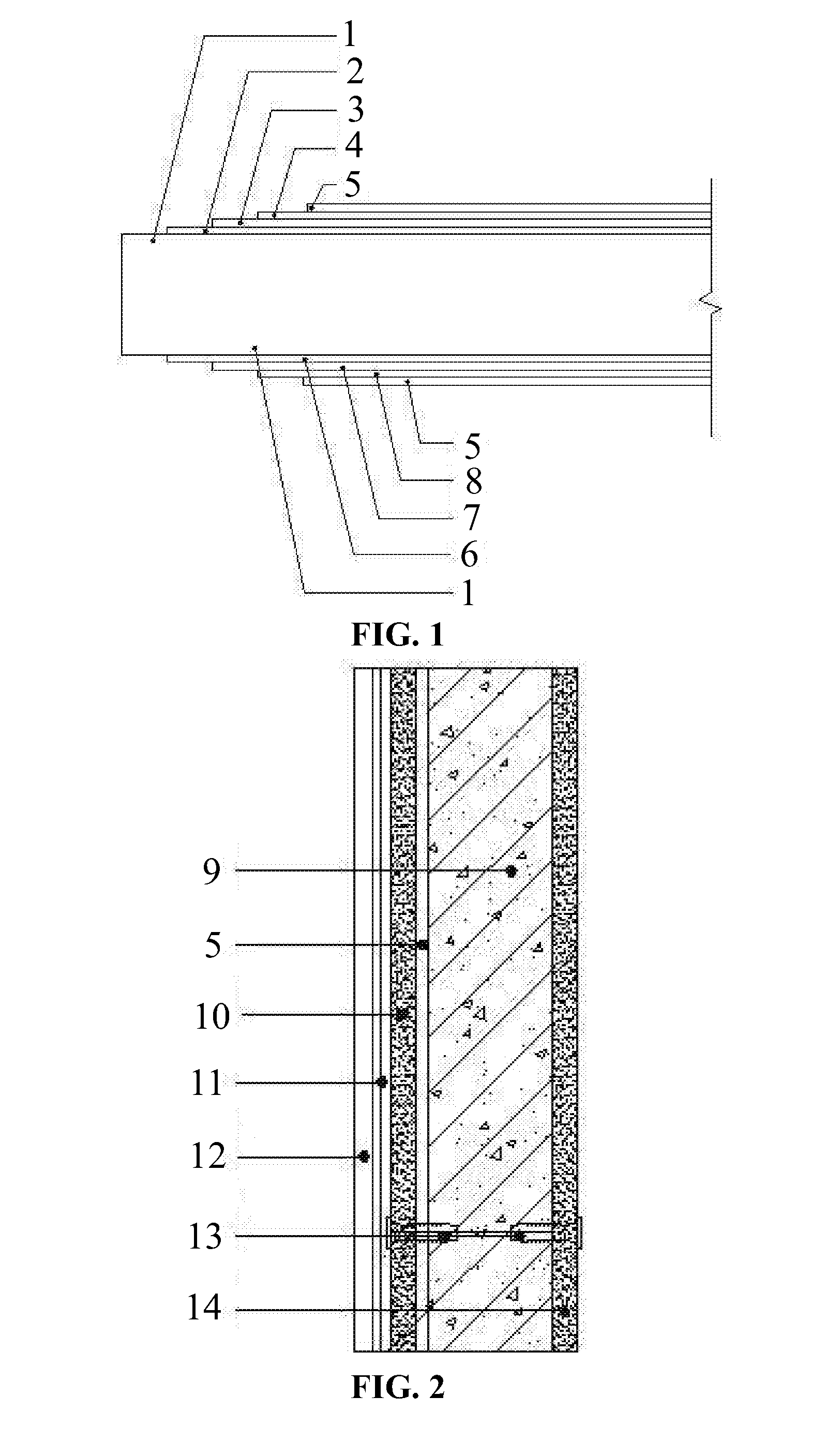

Thermal insulation wallboard and method for producing the same

a technology of thermal insulation wallboard and thermal insulation material, which is applied in the direction of heat-proofing, other domestic articles, synthetic resin-layered products, etc., can solve the problems of difficult control of construction quality, poor waterproof properties of constructed walls, and time-consuming wall use of thermal insulation materials, etc., to achieve simple structure, light weight and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0057]The production method for the non-dismantling thermal insulation wallboard adopts the following steps:

[0058]1. Production of the thermal insulation board:

[0059]1) Mix mineral cotton, expanded perlite, starch, waterproof agents, fire retardants, flocculating agents, fiberglass, paper pulp and water in proportion to their weights. Put the mixture into the stirring tank until the mixture becomes paste which is made into wet boards by full-hole grouting method, in which, the proportions of mineral cotton, expanded perlite, starch, waterproof agents, fire retardants, flocculating agents, fiberglass, paper pulp and water are as follows:[0060]Mineral Cotton 1,[0061]Expanded Perlite 0.4,[0062]Corn Starch 0.1,[0063]Waterproof Agent (Acrylic Emulsion) 0.03,[0064]The Fire Retardant (Magnesium Hydroxide) 0.1,[0065]The Flocculating Agent (Aluminum Sulfate) 0.03,[0066]Fiberglass 0.02,[0067]Paper Pulp 0.03, and[0068]Water 150.

[0069]2) The wet boards are transported into a drying tunnel to be...

example 2

[0081]The production method for the non-dismantling thermal insulation wallboard adopts the following steps:

[0082]1. Production of the thermal insulation board:

[0083]1) Mix mineral cotton, expanded perlite, starch, waterproof agents, fire retardants, flocculating agents, fiberglass, paper pulp and water in proportion to their weights. Put the mixture into the stirring tank until the mixture becomes paste which is made into wet boards by full-hole grouting method, in which, the proportions of mineral cotton, expanded perlite, starch, waterproof agents, fire retardants, flocculating agents, fiberglass, paper pulp and water are as follows:[0084]Mineral Cotton 1,[0085]Expanded Perlite 0.5,[0086]Cassava Starch 0.2,[0087]The Waterproof Agent (Pure Acrylic Emulsion) 0.05,[0088]The Fire Retardant (Aluminum Phosphate) 0.1,[0089]The Fire Retardant (Monopotassium Phosphate) 0.1,[0090]The Flocculating Agent (Aluminum Sulfate) 0.05,[0091]Fiberglass 0.01,[0092]Paper Pulp 0.05, and[0093]Water 200....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com