Synthesis Method for Controlling Antimony Selenide Nanostructure Shapes

a technology of antimony selenide and nanostructure, which is applied in the field of chemical synthesis, can solve the problems of poor material quality, and achieve the effect of poor material quality and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

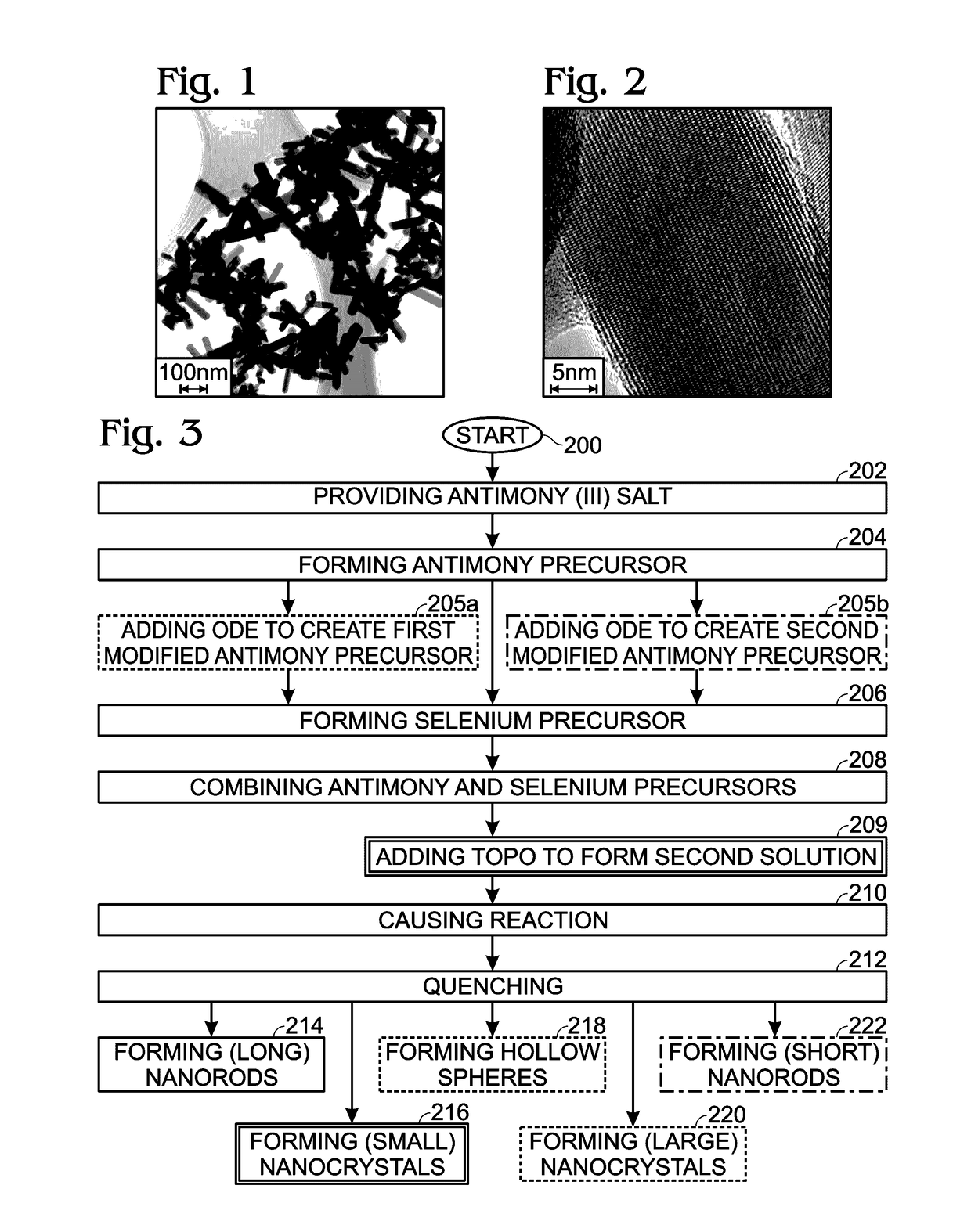

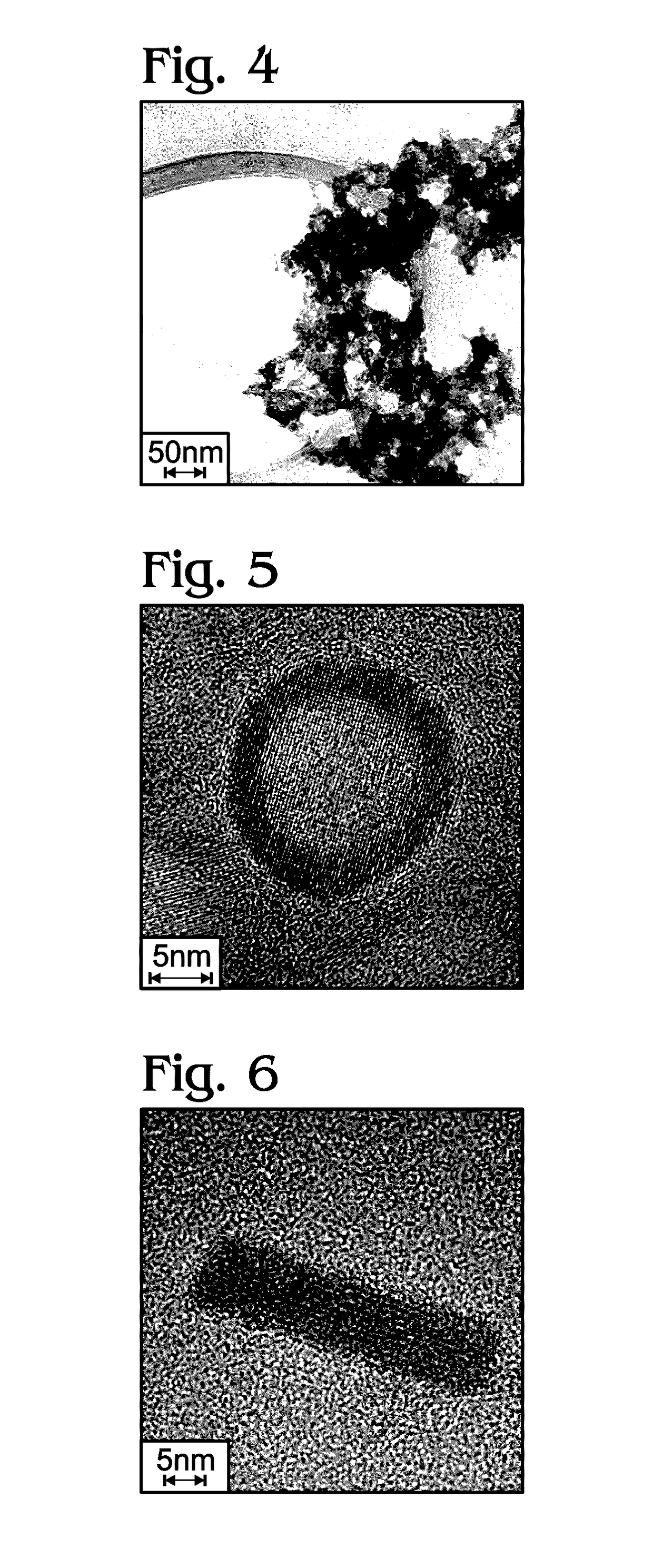

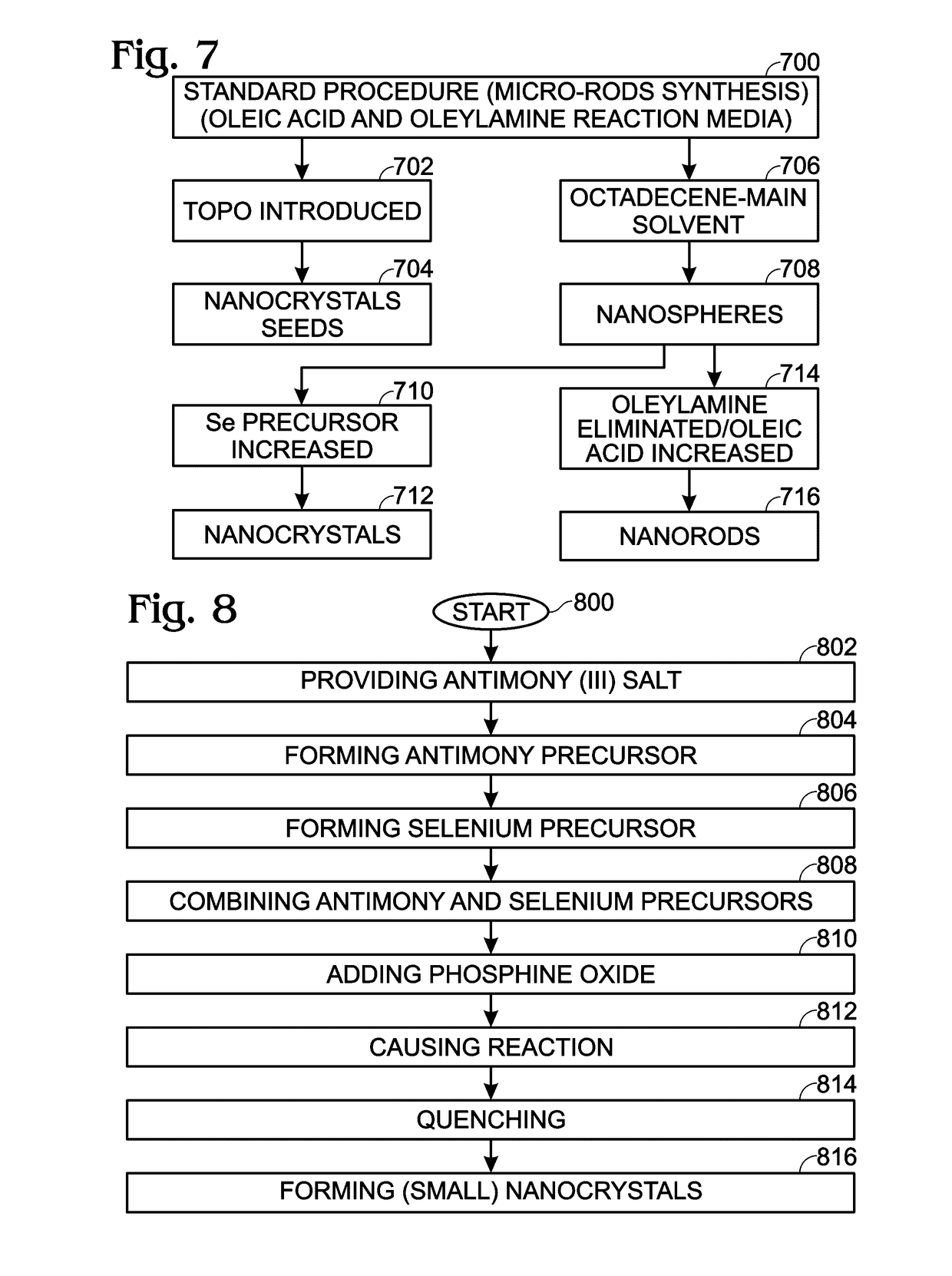

[0025]Different approaches can be applied for the selective synthesis of antimony selenide nanostructures. Although not explicitly described, similar principles can be applied towards the preparation of antimony sulfide or antimony telluride. It should be noted that the methods disclosed herein are the first known example of the direct colloidal chemical synthesis of antimony chalcogenides. The selective preparation is based upon the proper choice of the starting material as well as reaction media. Different surfactants, present in the reaction solution, which can be specifically introduced or obtained through the decomposition of the precursors, dictate the growth of the nanostructures in particular directions. Herein is presented the preparation of the nanorods, nanocrystals, and nano-hollow spheres.

[0026]One procedure for antimony selenide nanorod preparation can be described as follows: a 200 mg of antimony (III) chloride is dissolved in 3 milliliters (mL) of oleic acid at 150° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com