Method for preparing large graphene sheets in large scale

a graphene sheet and large-scale technology, applied in the direction of single-layer graphene, carbon-silicon compound conductors, chemistry apparatus and processes, etc., can solve the problems of difficult exfoliation of oxidized graphite, longer time and larger power consumption, and the cleaning process is difficult, so as to achieve no water washing, no water washing, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

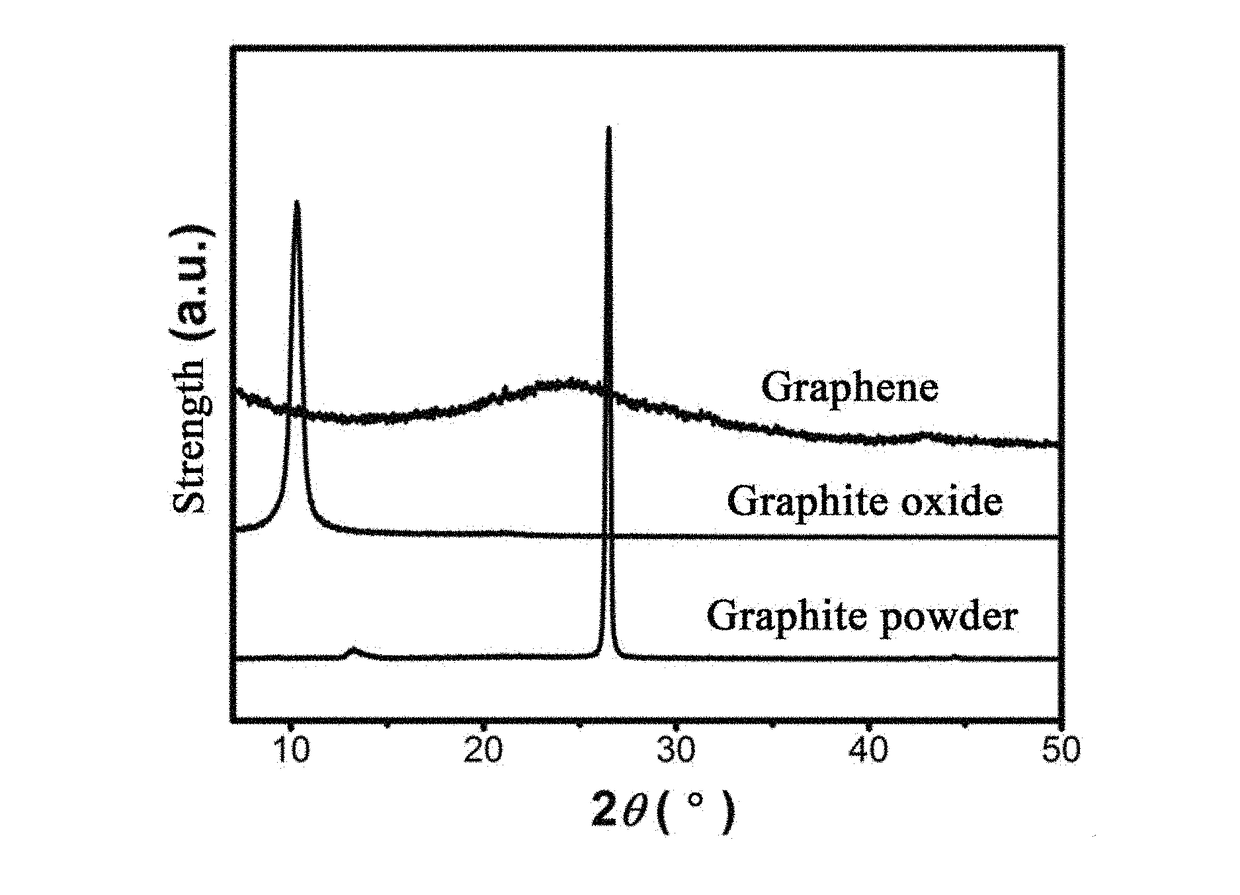

[0038]The first preferred embodiment relates to a method for preparing large graphene sheets in large scale, wherein a specific preparation process thereof is showed in FIG. 1, comprising steps of:

[0039]mixing 12 g 500 μm natural flake graphite with 260 ml concentrated sulphuric acid; slowly adding 60 g potassium permanganate in an ice bath; mixing evenly, and reacting in the ice bath for 2 hours; rising a temperature to 35° C.; continuing oxidizing for 48 hours; slowly adding 1.8 L deionized water and then adding 30 ml 20% (V / V) aqueous hydrogen peroxide solution; obtaining a mixed aqueous solution containing graphite oxide; processing the mixed aqueous solution containing the graphite oxide with vacuum filtration, obtaining filter cakes, washing respectively with 1 L 10% (V / V) and 1 L 0.5% (V / V) hydrochloric acid, washing off remaining metal ions and inorganic ions, and then drying at 60° C. for 48 hours; grinding the filter cakes into powders by a family-use grinder, treating for...

second preferred embodiment

[0043]The second preferred embodiment relates to a method for preparing large graphene sheets in large scale, wherein a specific preparation process thereof is showed in FIG. 1, comprising steps of:

[0044]mixing 12 g 500 μm expandable graphite with 720 ml concentrated sulphuric acid; slowly adding 120 g potassium chlorate in an ice bath; evenly mixing and reacting in the ice bath for 48 hours; rising a temperature to 35° C.; continuing oxidizing for 36 hours; slowly adding 2 L deionized water and then adding 240 ml hydrogen peroxide; obtaining a mixed aqueous solution containing graphite oxide; processing the mixed aqueous solution containing the graphite oxide with vacuum filtration, obtaining filter cakes, washing respectively with 2 L 10% (V / V) and 1 L 0.5% (V / V) hydrochloric acid, washing off remaining metal ions and inorganic ions, and then drying at 85° C. for 100 hours; grinding the filter cakes into powders by a family-use grinder, treating for 30 s at 850° C., and obtaining ...

third preferred embodiment

[0047]The third preferred embodiment relates to a method for preparing large graphene sheets in large scale, wherein a specific preparation process thereof is showed in FIG. 1, comprising steps of:

[0048]mixing 12 g 300 μm graphite powders with 480 ml perchloric acid; slowly adding 90 g potassium persulfate in an ice bath; evenly mixing and reacting in the ice bath for 20 hours; rising a temperature to 35° C., and continuing oxidizing for 120 hours; slowly adding 2.4 L deionized water and then adding 24 ml hydrogen peroxide; obtaining a mixed aqueous solution containing graphite oxide; processing the mixed aqueous solution containing the graphite oxide with vacuum filtration, obtaining filter cakes, washing respectively with 1.4 L 10% (V / V) and 1 L 1% (V / V) hydrochloric acid, washing off remaining metal ions and inorganic ions, and then drying at 30° C. for 200 hours; grinding the filter cakes into powders by a family-use grinder, treating for 30 s at 500° C., and obtaining the large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com