Multi-station continuous hot stamping production line and method

a production line and continuous hot stamping technology, applied in the field of hot stamping, can solve the problems of reducing heating efficiency, large heat loss, oxidation, etc., and achieve the effects of improving energy utilization and heating efficiency, high heating efficiency and speed, and reducing heat loss and air oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present disclosure will be further explained below in connection with the accompanying drawings and embodiments so that the objectives, the technical solutions, and advantages of the present disclosure can be clearer. It should be appreciated that the specific embodiments described below are intended only for explaining, rather than, limiting the present disclosure.

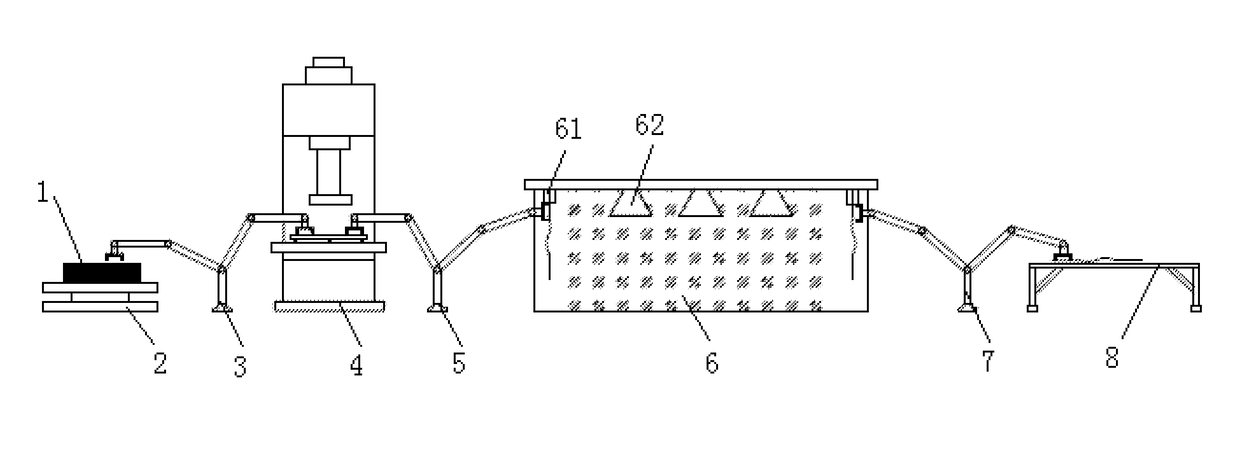

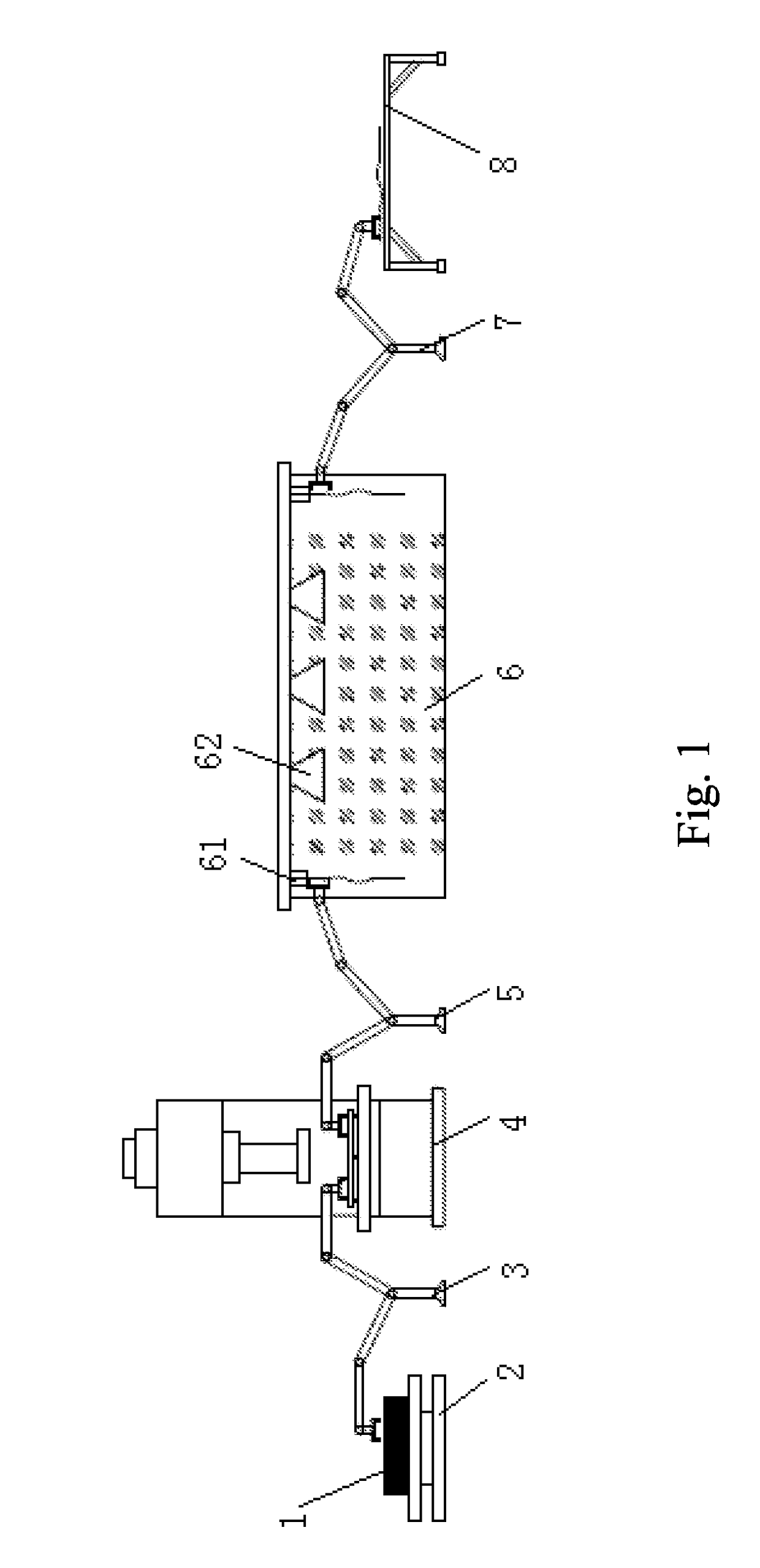

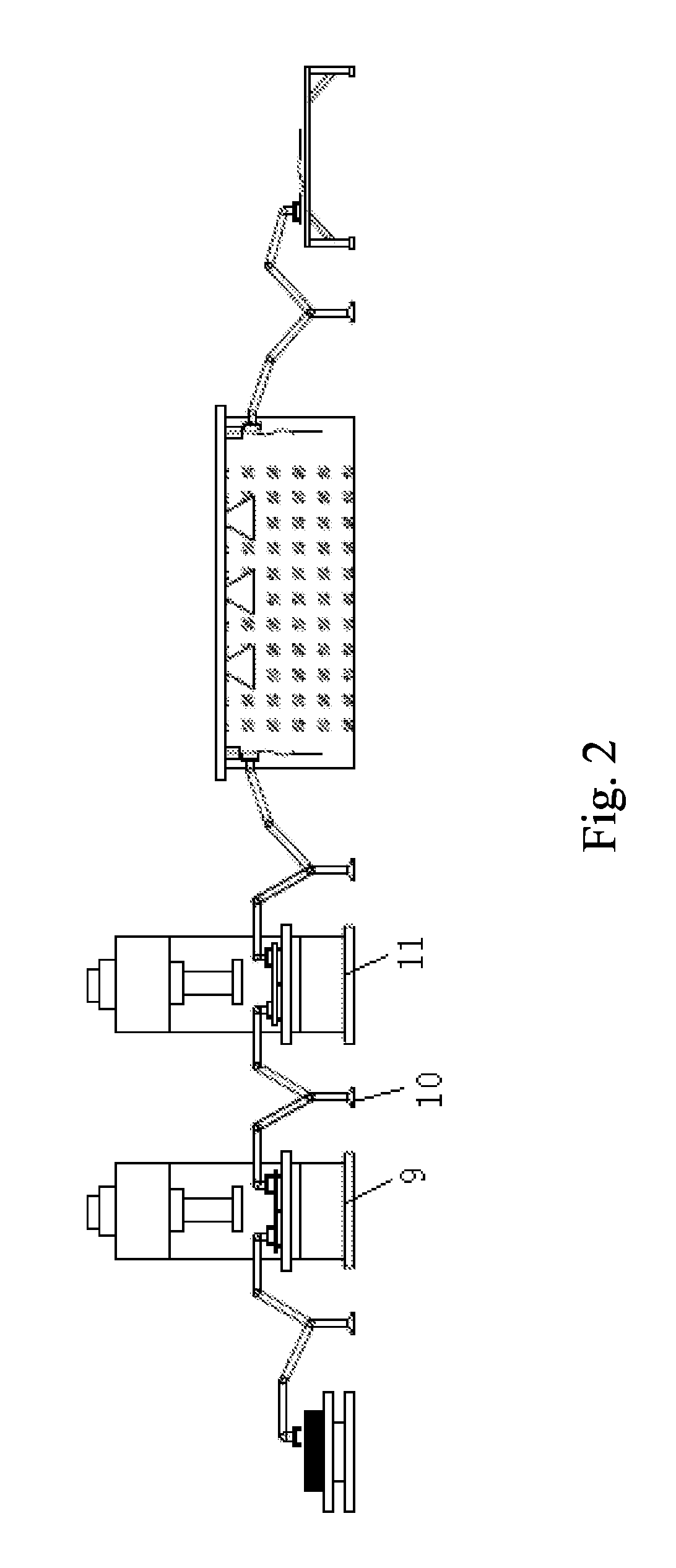

[0034]As shown in FIGS. 1 to 5, a multi-station continuous hot stamping production line comprises a feeding platform 2, a feeding robot 3, a pressing unit, a conveying robot 5, a quenching device, a discharging robot 7, and a conveyor belt 8. The feeding platform 2 is used for placing a preformed blank 1 after blanking. The feeding robot 3 is used for transferring the preformed blank 1 to the pressing unit. The pressing unit includes a heating device, a die device, and at least a press used for mounting the die device. The heating device is used for wholly or partially heating the preformed blank to produce a ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com