Ferroelectric device and method for manufacturing same

a technology of ferroelectric devices and magnetic fields, applied in the direction of solid-state devices, chemical vapor deposition coatings, coatings, etc., can solve the problems of inability to retain data, data written on the device when seen to operate as a memory transistor the data written on the device when seen to operate as a memory transistor does not disappear in one day at the longest after writing, etc., to achieve the effect of widening the memory window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

Example 1

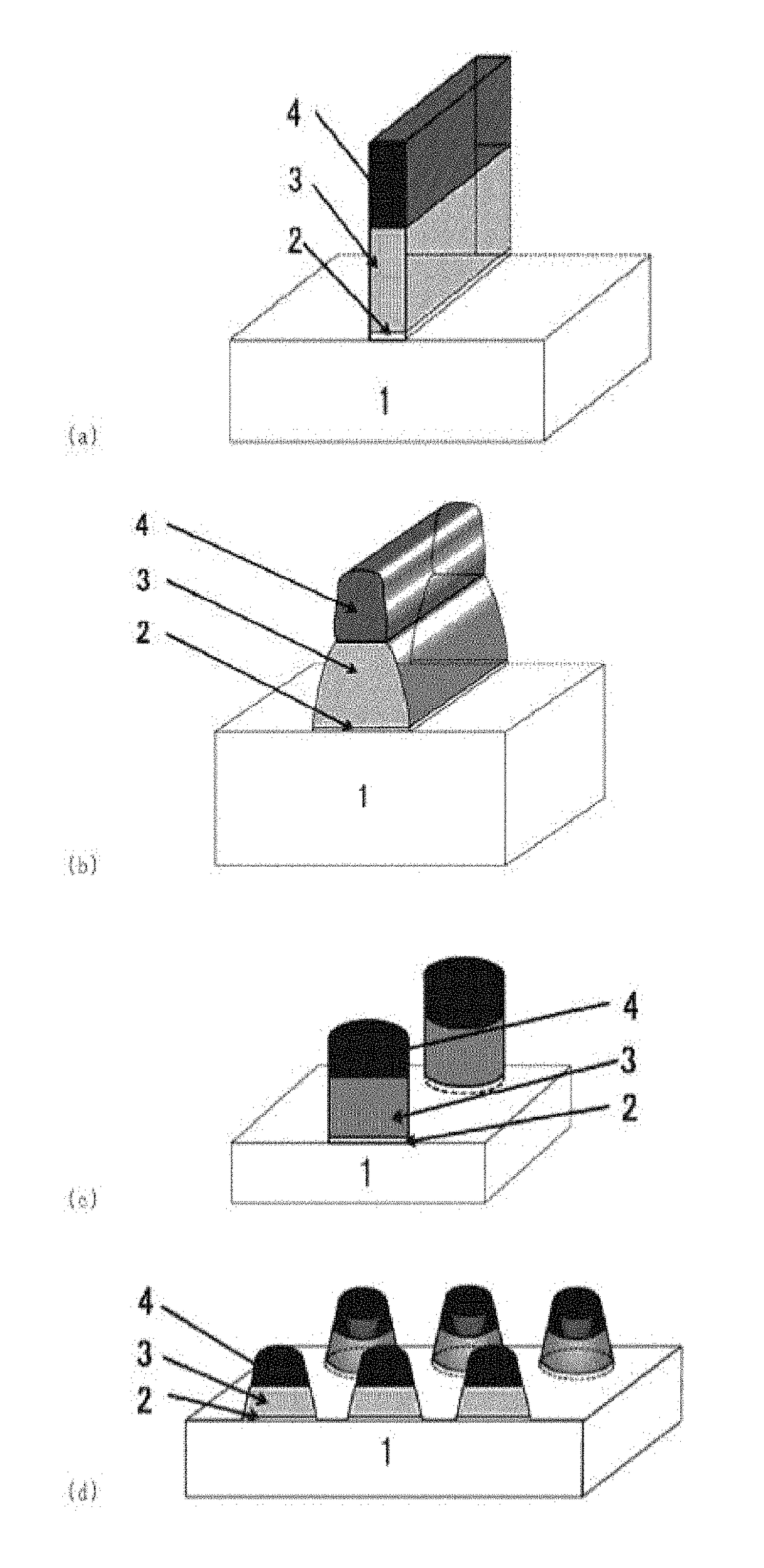

[0257]In Example 1 as an embodiment of the present invention, a transistor structured as shown in FIG. 1 is made.

[0258]Materials used, thicknesses and others are as follows:[0259]Semiconductor 1 constituted by a Si substrate having a source and a drain region preformed.[0260]Insulator 2 composed of HfO2, and having a thickness of 7 nm.[0261]First Ferroelectric, i.e. Ferroelectric 3 composed of SCBT and having a thickness of 200 nm[0262]Conductor 4 composed of Pt and having a thickness of 200 nm.[0263]Gate length (length of gate metal from the source region towards the drain region) of 10 μm[0264]Type of conduction of the source and drain regions 5 and 6: n type[0265]Type of conduction of region 7: p type

[0266]HfO2 is formed as built up by pulse laser deposition. The laser used is KrF excimer laser. Laser excimer is of 250 mJ per pulse and a repetition frequency of pulses: 2 Hz. The substrate has a temperature of 220° C. Gas introduced into a build-up chamber is nitrogen gas...

example 2

[0283]In Example 2, rates of flow of MOCVD liquid materials different from those in Example 1 are adopted. Also, the period of heat treatment for crystallization is altered. Other conditions are identical to those in Example 1. To wit:

[0284]Liquid Raw Materials

[0285]ST-1 (concentration of 0.1 M): 0.106 sccm

[0286]CT-1 (concentration of 0.1 M): 0.049 sccm

[0287]Bi (MMP)3: (concentration of 0.2 M): 0.146 sccm

[0288]PET (concentration of 0.1 M): 0.038 sccm

[0289]Film Forming Time Period: 1457 seconds

[0290]Heat Treatment Conditions: heat treatment in oxygen under the atmospheric pressure, at a temperature of 800° C. and for a time period of 60 minutes.

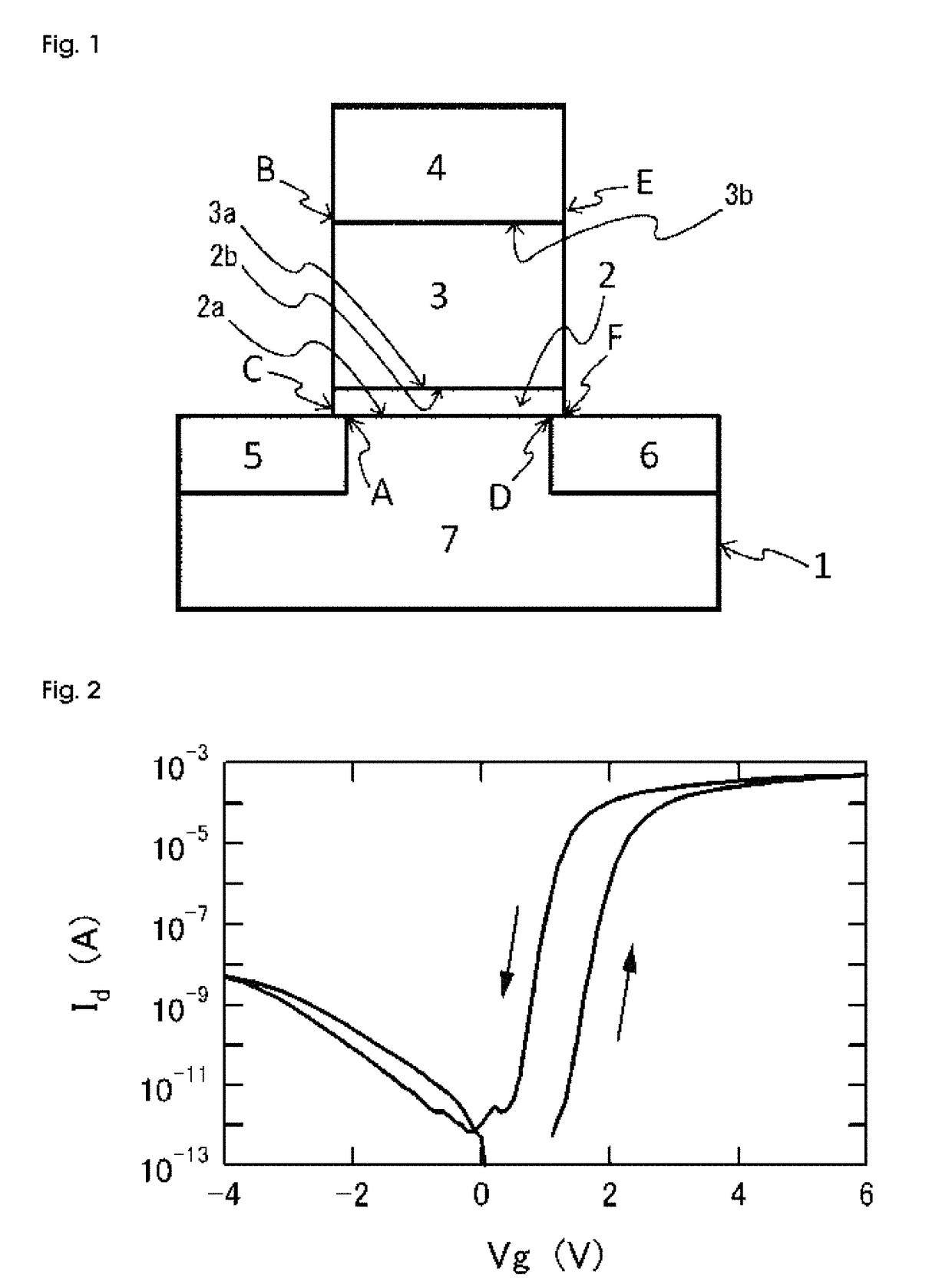

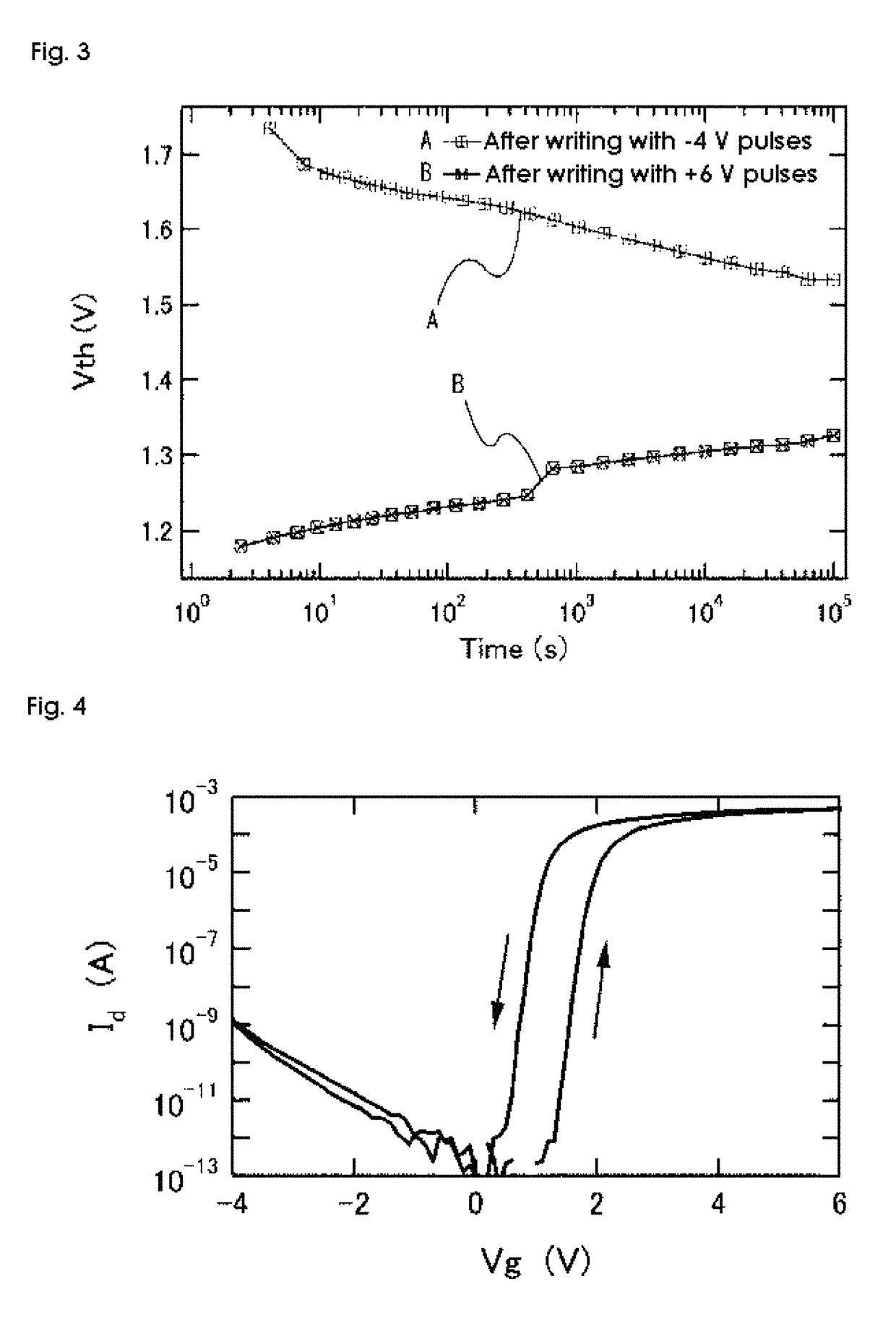

[0291]FIG. 4 shows Id−Vg characteristics. Measurement as is that in FIG. 2 is made in which the gate voltage is swept in reciprocation between −4 and 6 V. At Id=2×10−6 A, a memory window of 0.84 V is had.

example 3

[0292]In this Example, a substrate temperature different from those in Examples 1 and 2 is used. Also, the rates of flow of MOCVD liquid materials and the period of heat treatment for crystallization are altered. Also, the time period of heat treatment for crystallization is 1 hour. Other conditions are identical to those in Example 1. To wit:

[0293]Substrate Temperature: 450° C.

[0294]Liquid Raw Materials

[0295]ST-1 (concentration of 0.1 M): 0.097 sccm

[0296]CT-1 (concentration of 0.1 M): 0.032 sccm

[0297]Bi (MMP)3: (concentration of 0.2 M): 0.140 sccm

[0298]PET (concentration of 0.1 M): 0.032 sccm

[0299]Film Forming Time Period: 1940 seconds

[0300]Heat Treatment Conditions: heat treatment in oxygen under the atmospheric pressure, at a temperature of 800° C. and for a time period of 30 minutes.

[0301]FIG. 5 shows Id−Vg characteristics. Measurement as is that in FIG. 2 is made in which the gate voltage is swept in reciprocation between −4 and 6 V. At Id=2×10−6 A, a memory window of 0.75 V is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gate length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com