Spring steel for suspension and method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

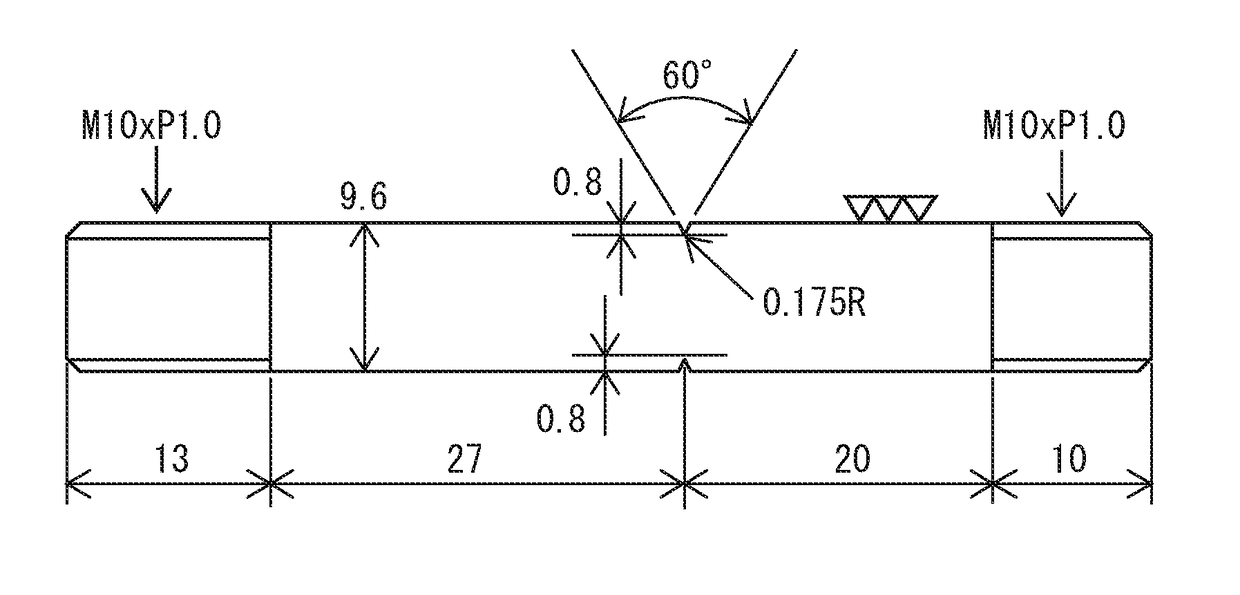

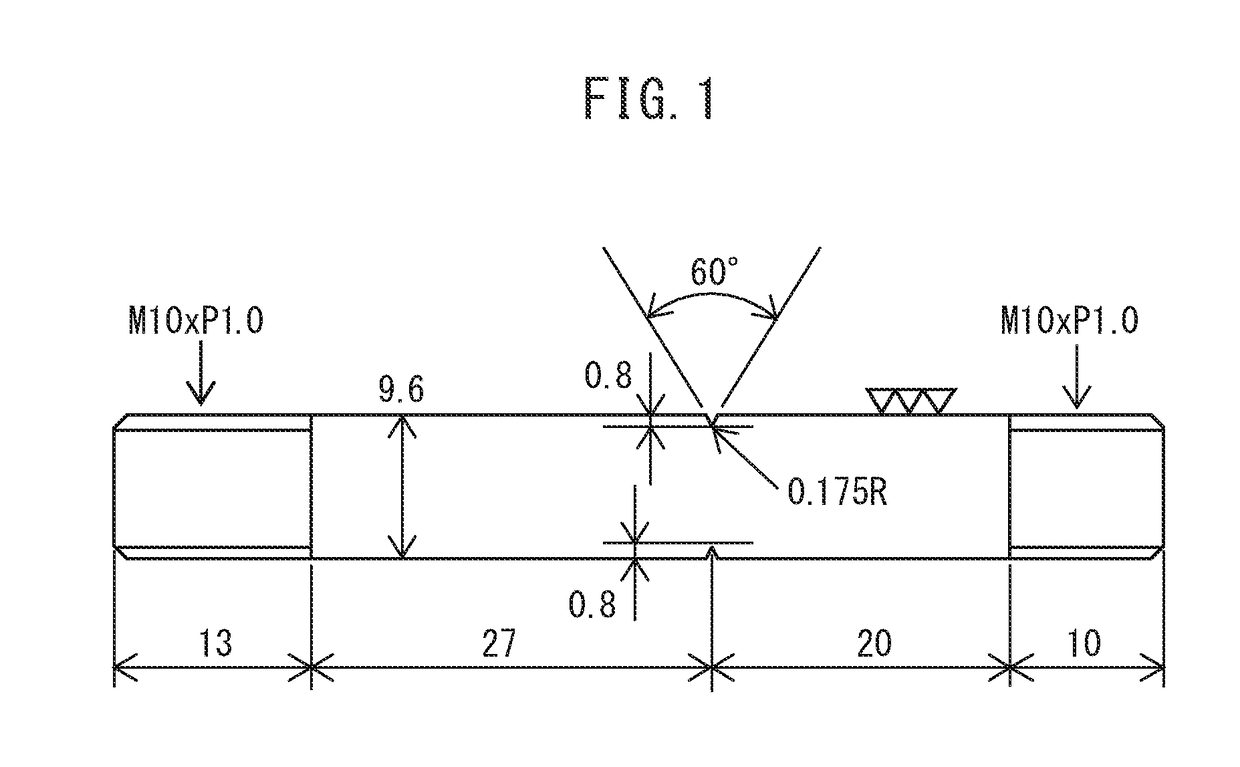

Image

Examples

examples

[0085]The inventors used round bar steel having the components shown in Table 1 and diameters of 11.5 to 20.0 mm, and processed by hot rolling, quenching, and tempering under the condition shown in Table 2, and conducted observation of their microstructures, tensile tests, and delayed fracture tests to evaluate the martensite structure fraction (also called the “martensite fraction”, aspect ratio of prior austenite grains, / fraction ratio, tensile strength, reduction of area in tensile test, and critical hydrogen content. In all of the examples, the quenching conditions were cooling by a cooling speed of 50° C. / sec or more until the surface temperatures become 30° C. In Table 1 and Table 2, Examples 1 to 19 are working examples while Examples X1 to X11 are comparative examples.

[0086]The martensite fraction was calculated from observation of the microstructure by an optical microscope. The L-cross-section of the round bar steel cut parallel to the rolling direction was polished to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com