NITRIDE INHIBITORS FOR HIGH SELECTIVITY OF TiN-SiN CMP APPLICATIONS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

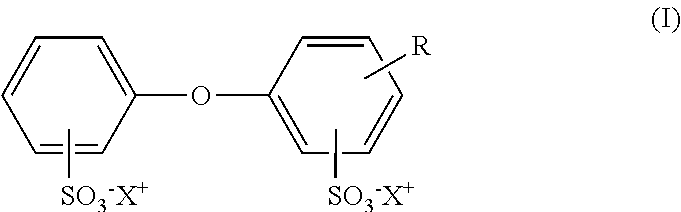

[0091](1) In embodiment (1) is presented a chemical-mechanical polishing composition comprising (a) alumina particles, wherein the alumina particles have a surface that comprises an anionic polymer, (b) a removal rate inhibitor selected from (I) a surfactant comprising a polyoxyalkylene functional group and a sulfonate functional group, (II) surfactant comprising a polyoxyalkylene functional group and a sulfate functional group, (III) a first surfactant comprising a polyoxyalkylene functional group and a second surfactant comprising a sulfonate functional group, and (IV) a first surfactant comprising a polyoxyalkylene functional group and a second surfactant comprising a sulfate functional group, and (c) an aqueous carrier.

[0092](2) In embodiment (2) is presented the chemical-mechanical polishing composition of embodiment (1), wherein the wherein the alumina particles are present in the polishing composition at a concentration of about 0.001 wt. % to about 10 wt. %.

[0093](3) In embo...

example 1

[0120]This example demonstrates the effect of a removal rate inhibitor on the TiN:SiN selectivity of the inventive polishing method and composition.

[0121]Substrates comprising TiN or SiN were polished with nine polishing compositions (i.e., Polishing Compositions 1A-1I). Each of Polishing Compositions 1A-1I contained the following: 0.03 wt. % alumina particles treated with polysulfonic acid polymer as an abrasive and 0.5 wt. % hydrogen peroxide as an oxidizing agent. In addition, each polishing composition had a pH of 3.

[0122]Polishing Composition 1A was a control and did not contain a removal rate inhibitor.

[0123]Polishing Compositions 1B-1I were inventive and contained one or more of the following removal rate inhibitors, as indicated in Table 1: alpha-olefin sulfonate (AOS); TWEEN™20; ZETASPERSE™2300 (Z2300); DOWFAX™ C10L; SINONATE™ 1150SF; and / or sodium polyoxyethylene lauryl ether sulfate (EMAL™ 20C).

[0124]Polishing Compositions 1B-1E were one-component compositions wherein the...

example 2

[0131]This example demonstrates the effect of a removal rate inhibitor and abrasive on the TiN:SiN selectivity of the inventive polishing method and composition.

[0132]Substrates comprising TiN or SiN were polished with eleven polishing compositions (i.e., Polishing Compositions 2A-2K). Each of Polishing Compositions 2A-2K contained alumina particles treated with polysulfonic acid polymer or colloidal silica particles (PL-3D or PL-2, FUSO) as an abrasive, and 0.5 wt. % hydrogen peroxide as an oxidizing agent. In addition, each polishing composition had a pH of 3.

[0133]Polishing Compositions 2A, 2D, and 2F were controls and did not contain a removal rate inhibitor. Polishing Compositions 2B, 2C, 2E, and 2G-2K were inventive and contained one or more of the following removal rate inhibitors, as indicated in Table 2: alpha-olefin sulfonate (AOS); TWEEN™20; ZETASPERSE™2300 (Z2300); DOWFAX™ C10L; SINONATE™ 1150SF; and / or sodium polyoxyethylene lauryl ether sulfate (EMAL™ 20C).

[0134]Invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com