Process for improving shelf-life of fresh cut vegetables and food products produced thereby

a technology of fresh cut vegetables and food products, applied in the field of freshcut/fresh vegetable shelf life improvement processes, to achieve the effect of improving the shelf life of fresh cut vegetables, reducing water activity and ph, and reducing time and temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Shelf-Life Extension Using Supercritical CO2

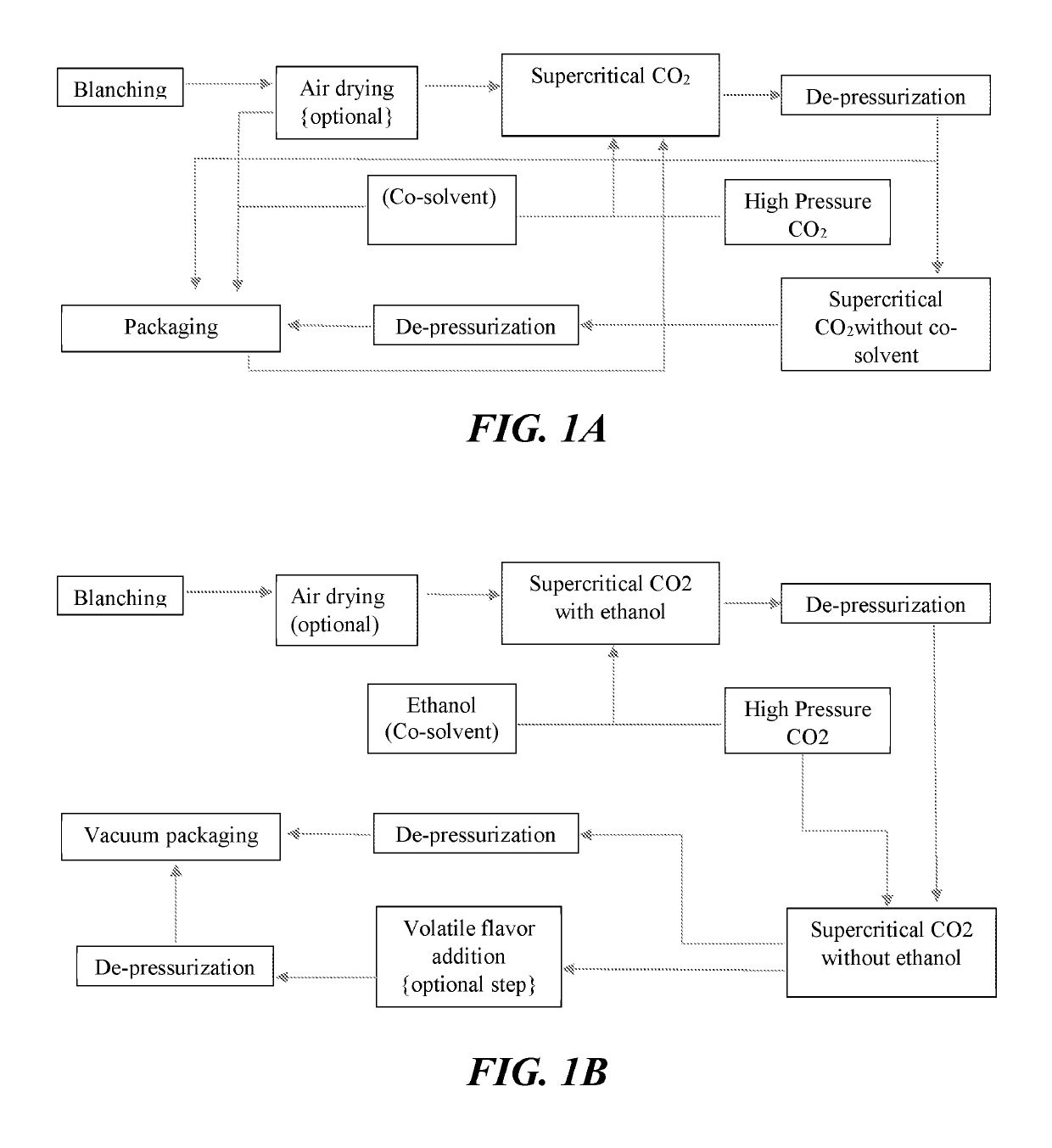

[0101]One embodiment of a process of the present disclosure is illustrated in the process flow diagram of FIG. 1A. As shown in FIG. 1A, the process can include the use of supercritical CO2 and the following steps: blanching, air drying (optional), supercritical CO2 (with a co-solvent), de-pressurization, supercritical CO2 (without a co-solvent), de-pressurization, and packaging. Alternatively, as shown in FIG. 1A, this embodiment can include packaging of the vegetables after the air drying step and before the supercritical CO2 (with co-solvent) step.

[0102]Another embodiment of a process of the present disclosure is illustrated in the process flow diagram of FIG. 1B. As shown in FIG. 1B, the process can include the use of supercritical CO2 and the following steps: blanching, air drying (optional), supercritical CO2 (with ethanol as the co-solvent), de-pressurization, supercritical CO2 (without the ethanol co-solvent), de-pressurization, an...

example 2

Various Embodiments of Process Parameters for Shelf-Life Extension of Fresh-Cut Vegetables

[0113]Various embodiments of the processes of the present disclosure are provided below.

[0114]In one embodiment of the process of the present disclosure, the process can involve the following combination of steps: (i) Peeling; (ii) Cutting (length −0.8 cm; width −0.6 cm; breath-0.6 cm); (iii) Blanching (65-90° C. for 5-15 minutes); (iv) Air drying (50-100° C. for 10-25 minutes); (v) Supercritical CO2+ethanol (150-350 Bar; 50-90° C.; CO2 flow rate 2-100 L / minute to provide a residence time of 10 seconds to iminute; Ethanol flow rate 2-8 mol of the CO2 flow rate %) @ 10-45 minutes {continuous flow}; (vi) Depressurization of the vessel; (vii) Supercritical CO2 (150-350 Bar; 50-90° C.; CO2 flow rate 2-100 L / minute to provide a residence time of 10 seconds to iminute) @ 10-45 minutes, Final moisture removal—40-45% {continuous flow}; (viii) Depressurization of the vessel; and (ix) Vacuum packaging.

[0...

example 3

Shelf-Life Extension of Potato Products

Material and Methods

Preparation of Potato:

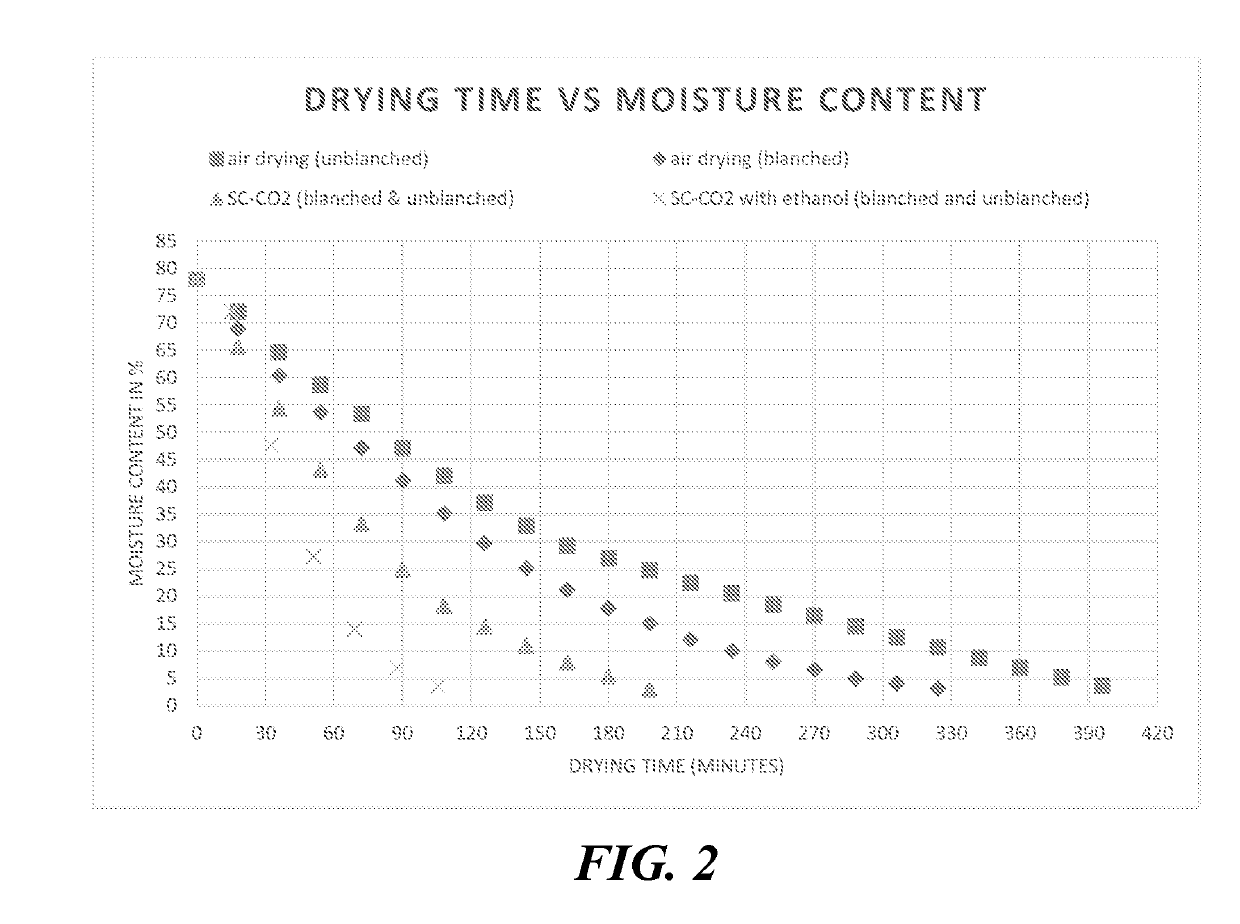

[0123]Potato were peeled and cut in the standard dimensions of French fries: length-5.90 cms; breath—0.8 cms; width-0.8 cms. The initial moisture content of the potato was calculated by drying the samples at 105° C. for 48 hours. The moisture content of the potato was calculated to be 78% on the basis of the mass loss, before and after drying.

Supercritical CO2 Drying:

[0124]During the process, CO2 from a cylinder (at 750 psi) was passed to a pump, which compresses the CO2. The compressed CO2 was preheated to the desired temperature with a heating element. Once the desired temperature and pressure was attainted for the CO2 in the vessel, the exit valves were opened to attain a constant flow rate of the CO2 through the product placed in the vessel. An external high pressure pump was attached to the system to inject the ethanol at a desired flow rate. At the end of the experiment the ethanol flow was stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com