Chemical treatment steel sheet and method for manufacturing chemical treatment steel sheet

a technology of chemical treatment steel and steel sheet, which is applied in the direction of electrolytic inorganic material coating, superimposed coating process, coating, etc., can solve the problems of black discoloration and corrosion, and achieve excellent corrosion resistance and sulfide stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

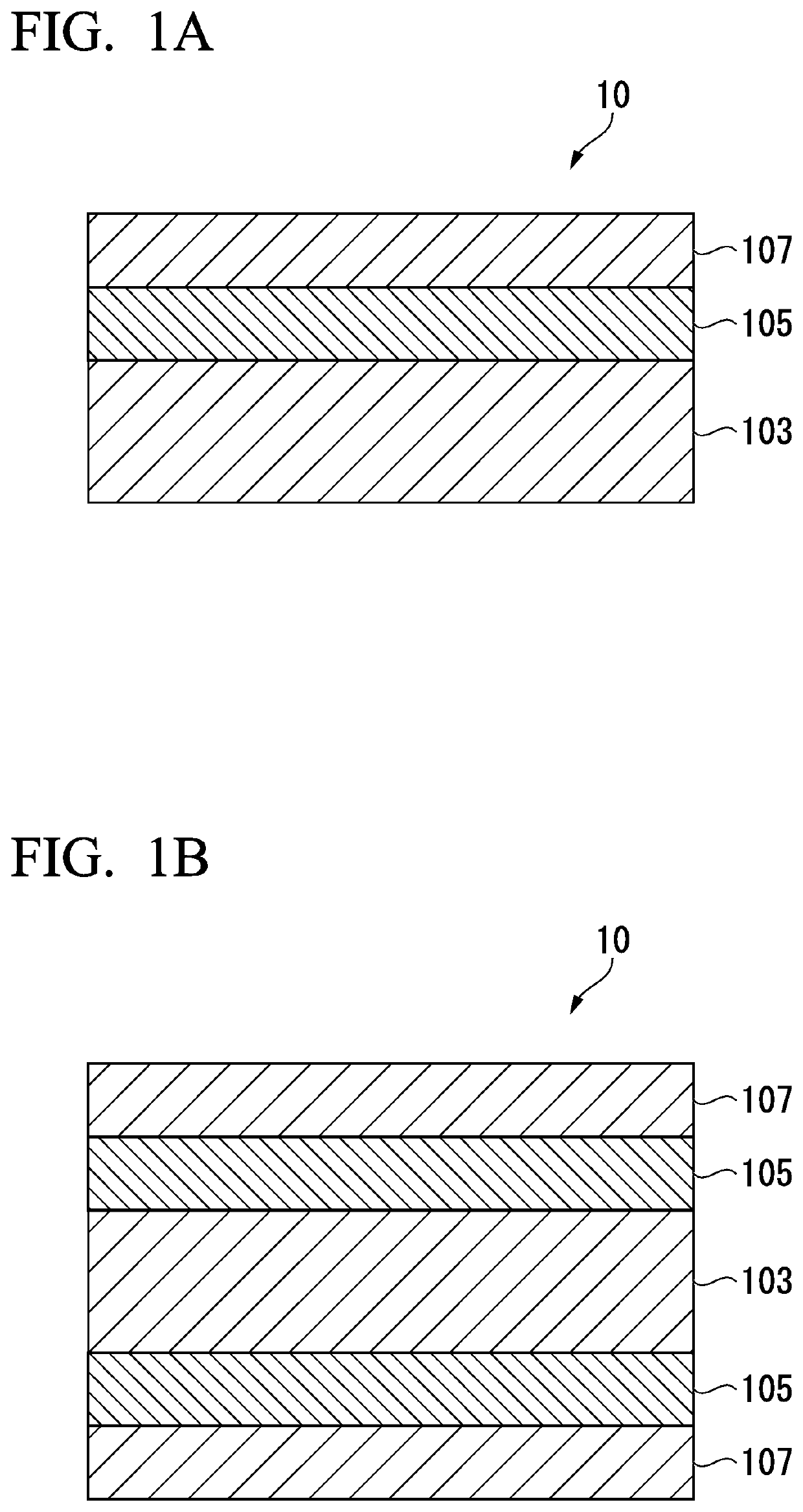

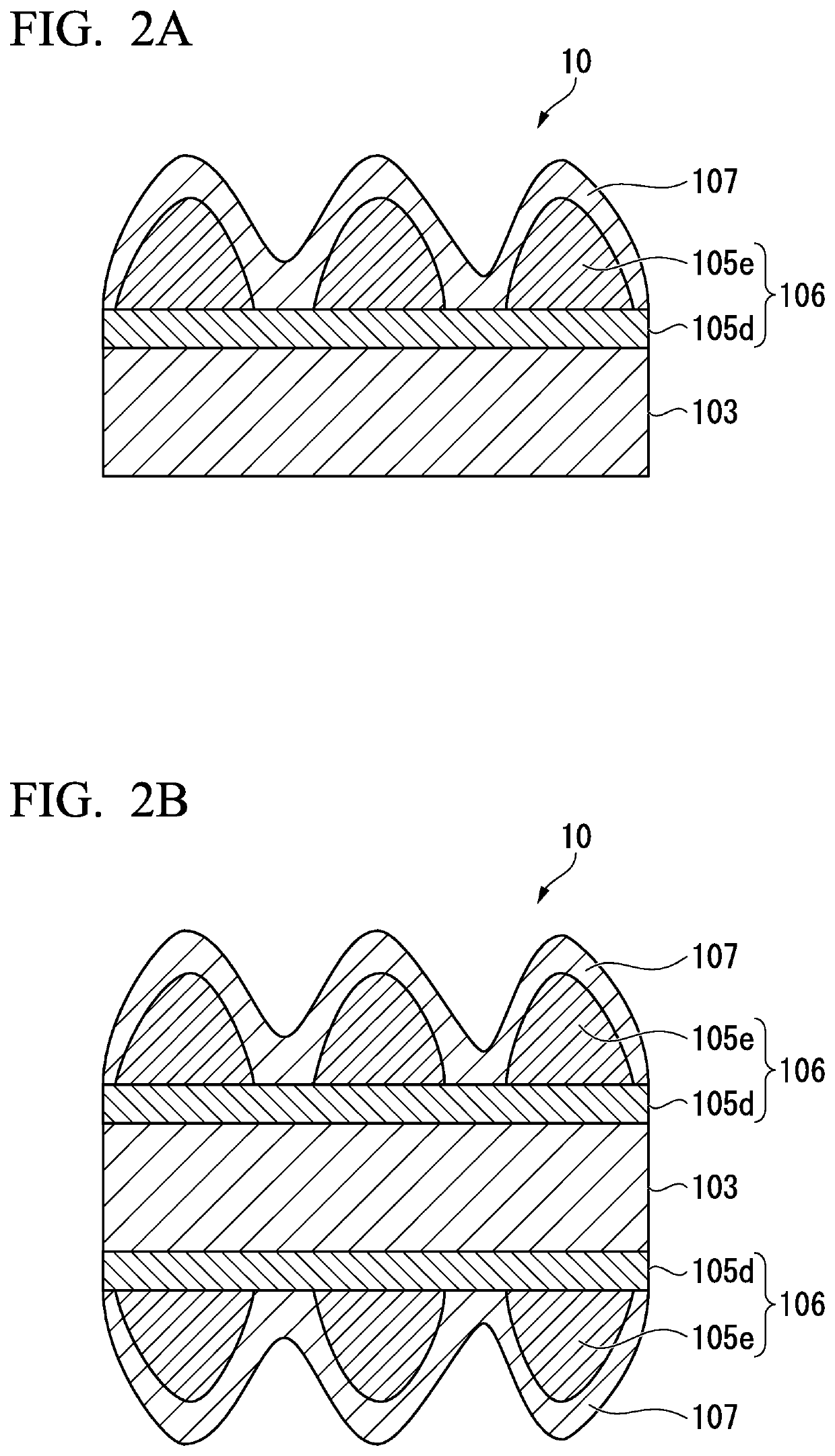

Image

Examples

example 1

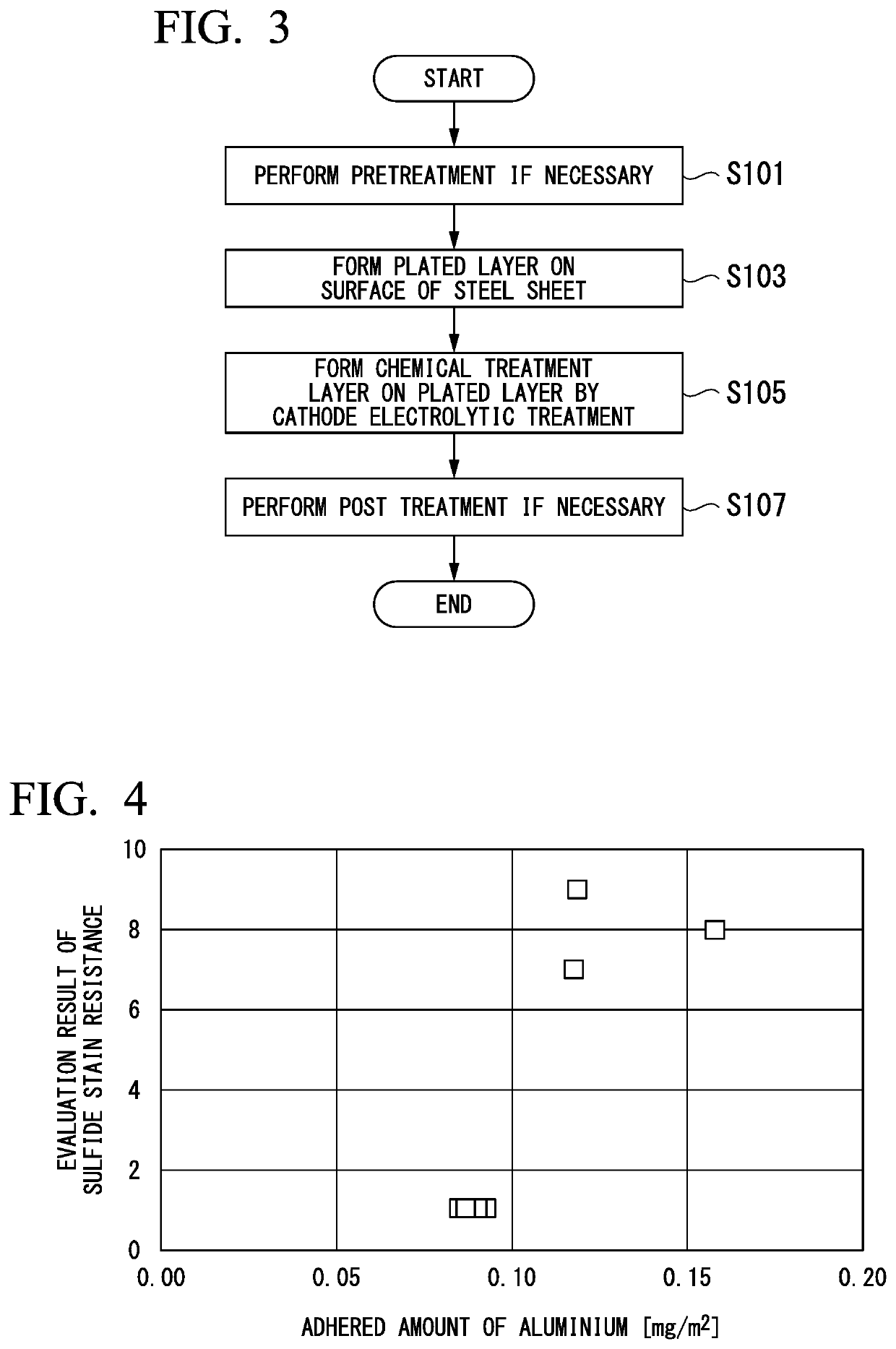

[0135]In Example 1, how a sulfide stain resistance changes was examined by changing the amount of Al compound without changing the Zr compound and phosphate compound content in a chemical treatment layer.

[0136]In Example 1, steel sheets which are generally used as steel sheets for containers were used as base materials and a Ni-plated layer was formed as a plated layer. The amount of Ni contained in the Ni-plated layer was set at 1000 mg / m2 per one surface in all samples. Furthermore, a chemical treatment layer is formed by changing a concentration of an Al compound in a chemical treatment layer for each sample to manufacture a plurality of samples. Here, in each sample, the amount of Zr contained in the Zr compound was 8 mg / m2 per one surface and the amount of P contained in the phosphate compound was 3 mg / m2 per one surface.

[0137]The sulfide stain resistance was evaluated as follows. First, a 0.6 mass % L-cysteine liquid boiled for one hour was put into a heat-resistant bottle and...

example 2

[0152]Next, how the sulfide stain resistance changes while a type of a plated layer and the amount of each component contained in a chemical treatment layer is changed was examined. In examples and comparative examples except for Comparative Example a5, a plated layer is any one of a Ni-plated layer and a composite plated layer. On the other hand, in Comparative Example a5, a composite plated layer is formed on a Ni-plated layer (two plated layers are formed).

[0153]Also, (NH4)3AlF6 was used as a supply source of Al ions in Examples A1 to A31 of the present invention and Comparative Examples a1 to a6, whereas Al2(SO4)3 was used as a supply source of Al ions in Comparative Examples a7 and a8 to form a chemical treatment layer.

[0154]The amounts of Ni metal and Sn metal contained in a plated layer and the amounts of Zr, P, and Al contained in a chemical treatment layer were measured using a fluorescent X-ray analysis.

[0155]In the Al2O3 content in a chemical treatment layer, first, peak ...

example 3

[0173]Next, how the sulfide stain resistance changes according to a type of plated layer and the each component contained in a chemical treatment layer was examined.

[0174]For each sample having a Ni-plated layer or a composite plated layer shown in Table 3, a chemical treatment was performed under the conditions shown in Table 4 (conditions for a chemical treatment solution and conditions for an electrolytic treatment). Table 5 shows the amounts of Zr, P, Al, and Al2O3 included in a chemical treatment layer formed on a plated layer of each sample.

[0175]Also, for each sample having a plated layer and a chemical treatment layer, corrosion resistance and sulfide stain resistance were evaluated as in Example 2. The results are shown in Table 5.

[0176](NH4)3AlF6 was used as a supply source of Al ions in Examples B1 to B31 of the present invention and Comparative Examples b1 to b8, whereas Al2(SO4)3 was used as a supply source of Al ions in Comparative Examples b9 and b10 to form a chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com