Composition Useful in Sulfate Scale Removal

a technology of sulfate scale and composition, applied in the field of composition, can solve the problems of sulfate scale, restrict or even shut off the production conduit, sulfate scale on surface equipment, heat exchangers and associated piping, etc., and achieve the effect of sufficient exposure tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

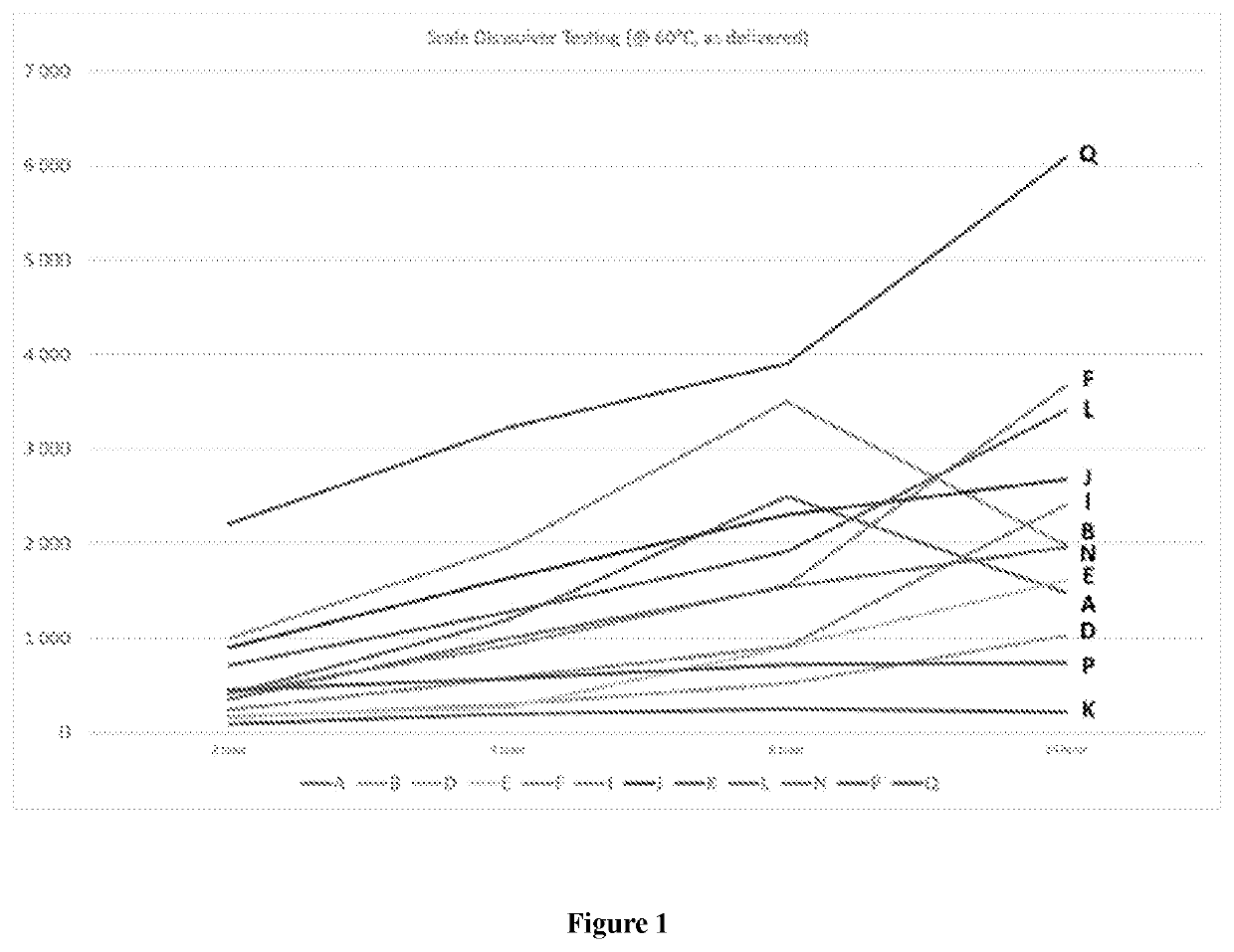

Image

Examples

Embodiment Construction

[0086]By the addition of potassium carbonate to K5DTPA, the same solubility numbers can be attained at a lower pH. Instead of 13.5 a pH of 11 was sufficient to get comparable solubility numbers. This represents a considerable difference to typical commercially available products. This allows an operator to conduct scale removal operations at a lower pH and therefore increases the safety for the personnel handling the remover or anyone in the surrounding area as well as environmental risks and clean up costs in the case of an uncontrolled release.

[0087]According to a preferred embodiment of the present invention, the mixed sulfate scale removing composition provides greatly improved rates of scale dissolution. This, in turn, reduces the down time for wells where the scale is being removed and associated the costs. It also reduces the cost of such treatment, by limiting the treatment time by allowing production to recommence.

[0088]As shown below, the compositions tested for removing n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com