Lubricating oil composition

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, base materials, additives, etc., can solve the problems of corrosion of copper contained in the engine members, problems in lifetime, etc., and achieve excellent metal corrosion resistance and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0193]Next, the present invention is described in more detail with reference to Examples, but the present invention is not whatsoever restricted by these Examples. Various properties of the components used in Examples and Comparative Examples and the lubricating oil compositions obtained therein were measured according to the methods mentioned below.

[0194]Measured or calculated according to JIS K 2283:2000.

[0195]Measured according to JPI-5S-38-03.

[0196]Measured according to JIS K2609:1998.

[0197]Measured according to JIS K2541-6:2013.

[0198]Measured according to JIS K2272:1998.

examples 1 to 12

, Comparative Examples 1 to 8

[0199]A base oil and various additives shown below were blended in a blending ratio shown in Tables 1 to 3, and well mixed to prepare lubricating oil compositions having a kinematic viscosity at 100° C. of 12.0 to 13.0 mm2 / s.

[0200]Details of the base oil and various additives used in Examples and Comparative Examples are as shown below.

(Component (A))

[0201]“Base oil (a)”: Hydrorefined 500N mineral oil grouped in Group 2 in the base oil category by API, 40° C. kinematic viscosity=89.3 mm2 / s, 100° C. kinematic viscosity=10.9 mm2 / s, viscosity index=107.

(Component (B1))

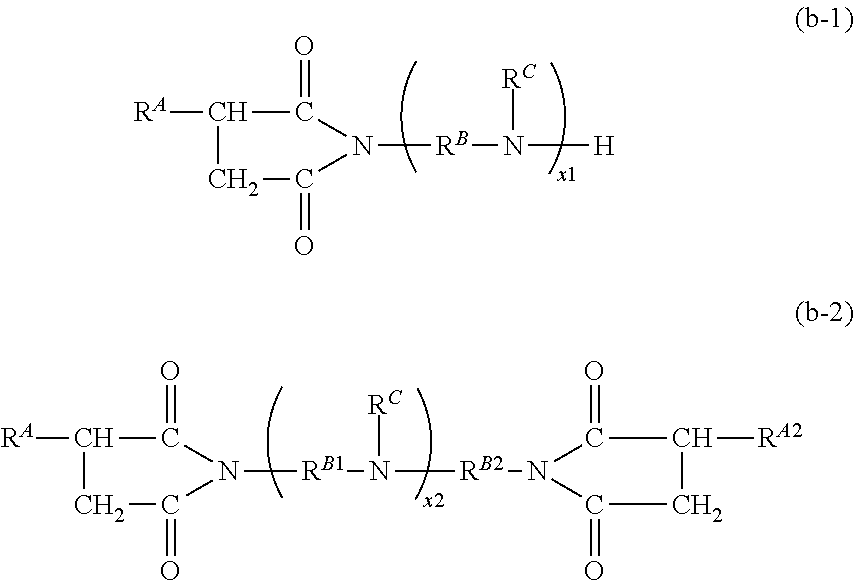

[0202]“Non-boronated alkenylsuccinic acid monoimide (b1)”: alkenylsuccinic acid monoimide represented by the general formula (b-1), wherein RA is a polybutenyl group having a number-average molecular weight (Mn) of 1000, nitrogen atom content=2.0% by mass.

(Component (B2))

[0203]“Boronated alkenylsuccinic acid monoimide (b2-1)”: boron-modified derivative of alkenylsuccinic acid monoimide represe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com