Heat exchanger for high stage generator of absorption chiller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 2

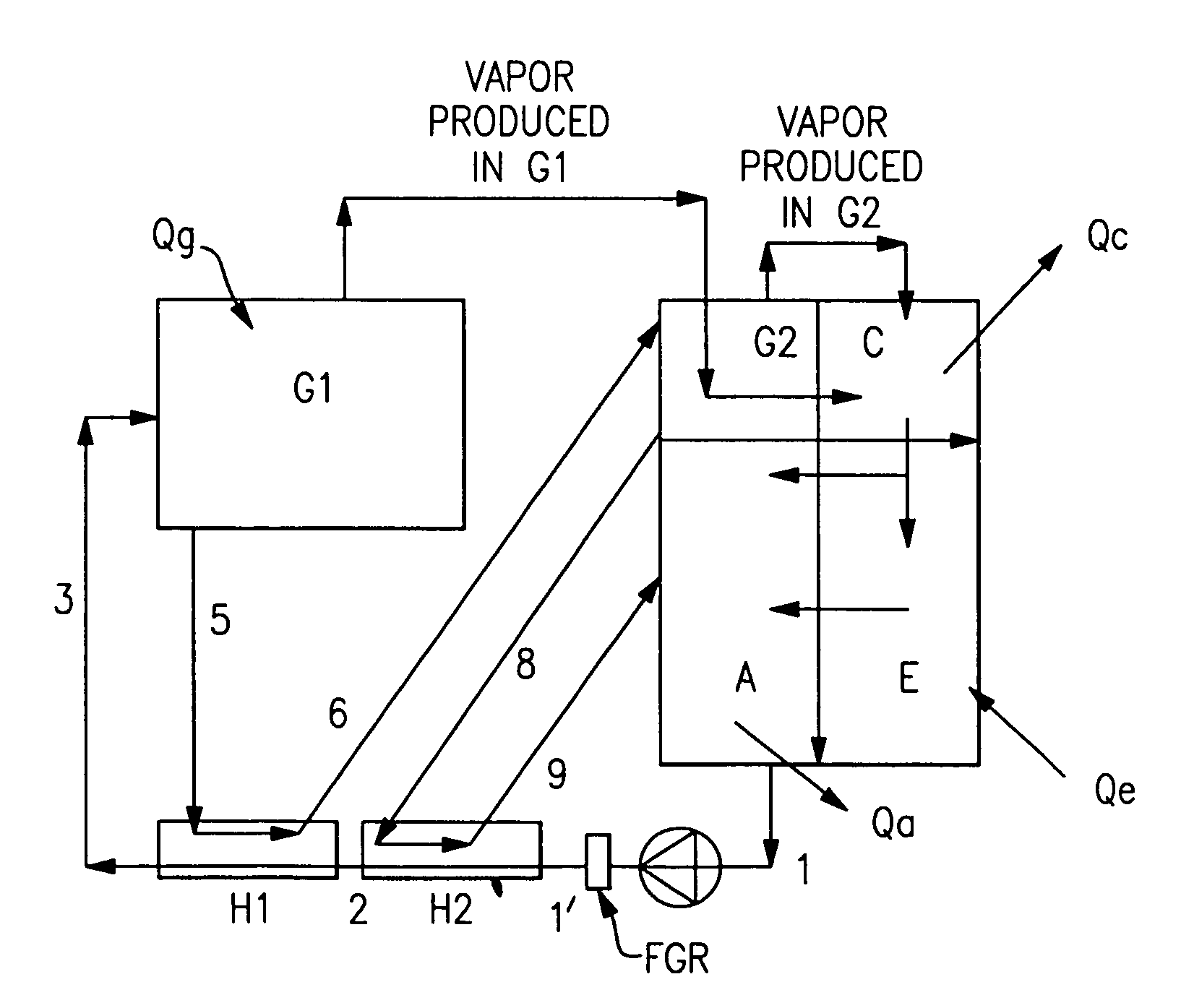

am of Solution Leaving Absorber

As shown in FIG. 7(b), a fraction of total solution flow leaving the absorber is passed through the FGR. If 10% of total energy input is recovered in FGR, and 10% of solution flow rate leaving absorber is bypassed in the FGR, then temperatures as shown in FIG. 7(b) can be achieved. Note that 1′–3′ is the heating of solution with FGR. In this situation, the risk of crystallization is the same as the baseline case of FIG. 1.

embodiment 3

am of Weak Solution Leaving H2

This embodiment is illustrated in FIGS. 8(a) and (b). It is similar to Embodiment 2, except instead of splitting a stream of solution leaving the absorber, a stream of weak solution is split leaving H2. In this case, the H2 leaving solution temperature is still at 72° C., but the split stream is heated with the FGR to 145° C., and the rest of the solution is heated to 145C in H1. In this embodiment, 2–3 is heating carried out in H1 while 2′–3′ is heating in the FGR.

embodiments 2 and 3

In embodiments 2 and 3, weak solution entering low temperature heat exchanger (H2) or high temperature heat exchanger (H1) is heated in FGR. Heated weak solution leaving FGR is mixed with either weak solution leaving H2 or weak solution leaving H1. It is important to bring the temperature of heated solution leaving FGR in close proximity to the temperature of solution in which it is being mixed to avoid mixing losses and improve thermodynamic efficiency of absorption cycle. This can be accomplished by two methods. First method is mechanical device such as a fixed orifice or a field adjustable valve. Second method is an electronically controlled valve.

FIG. 6(c) shows a scheme for embodiment 2, where heated solution from FGR is mixed with heated weak solution leaving H1. At full load, flue gas leaving high stage generator at full load is typically at 190–210C depending on efficiency of high stage generator. Weak solution leaving absorber is at typically at 38C. Assuming flue gas tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com