Plasma reactor having a symmetric parallel conductor coil antenna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first integrated embodiment

[0054]

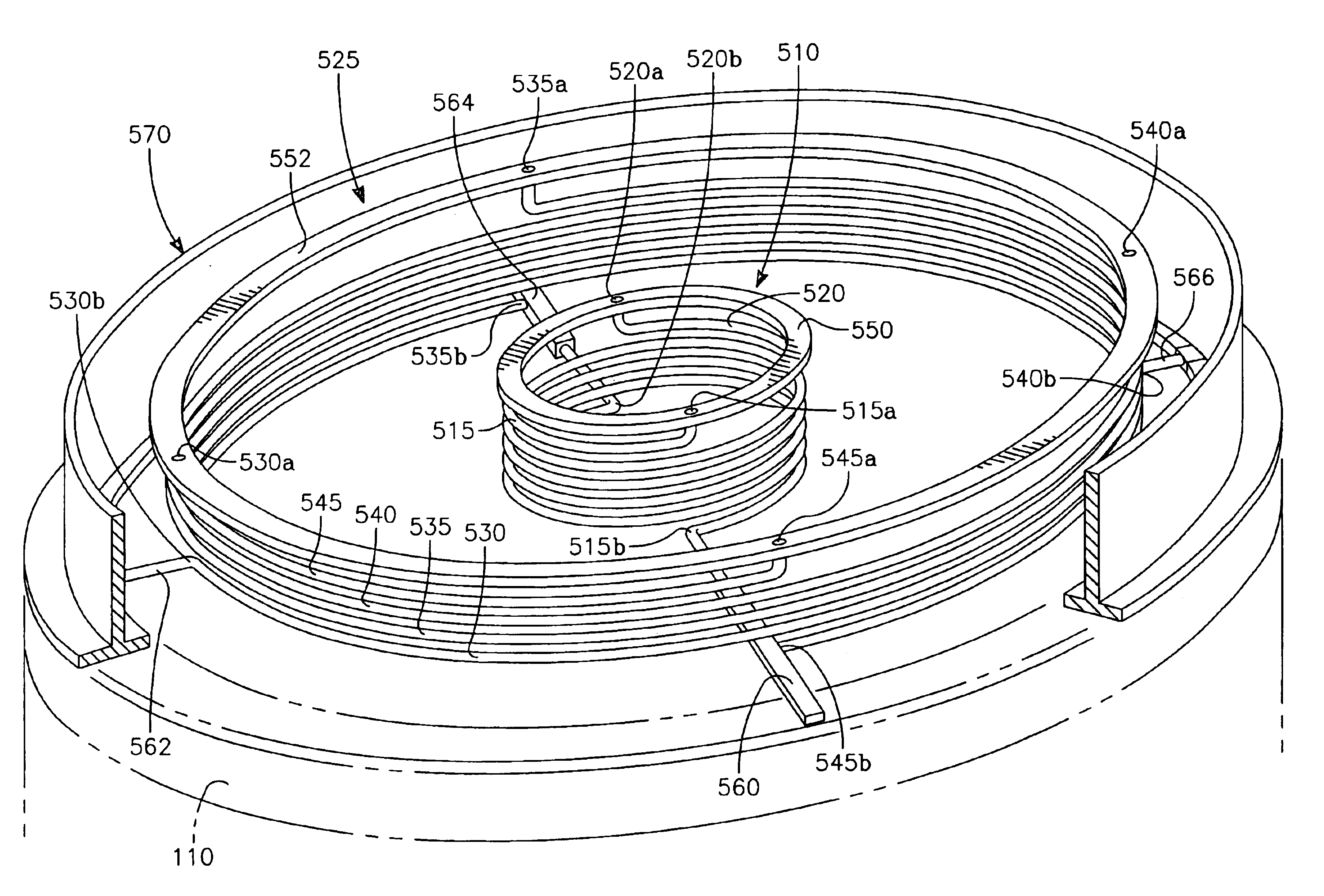

[0055]FIG. 5 illustrates a first integrated embodiment having multiple solenoidal overhead antennas, each having a plurality of interleaved conductors. An inner solenoidal antenna 510 has a pair of interleaved conductors 515, 520 with power taps 515a, 520a at 180 intervals. An outer solenoidal antenna 525 has four interleaved conductors 530, 535, 540, 545 with power taps 530a, 535a, 540a, 545a at 90 degree intervals with respect to the axis of symmetry. Each interleaved conductor is generally parallel to the remaining conductors of a given antenna. An inner circular power bus 550 overlying the inner antenna 510 is connected to the inner antenna power taps 515a, 520a. Similarly, an outer circular power bus 552 overlying the outer antenna 525 is connected to the outer antenna power taps 530a, 535a, 540a, 545a. A set of four arms 560, 562, 564, 566 underlying the outer antenna 525 and disposed at 90 degree intervals connect respective ground taps to a circular grounded housing 57...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com