Method of achieving jet separation of an un-separated flow in a divergent nozzle body of a rocket engine

a rocket engine and jet separation technology, applied in the direction of machines/engines, vessel construction, marine propulsion, etc., can solve the problems of jet separation, difficult to implement active secondary injection, and unstable position, and achieve the effect of avoiding such instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

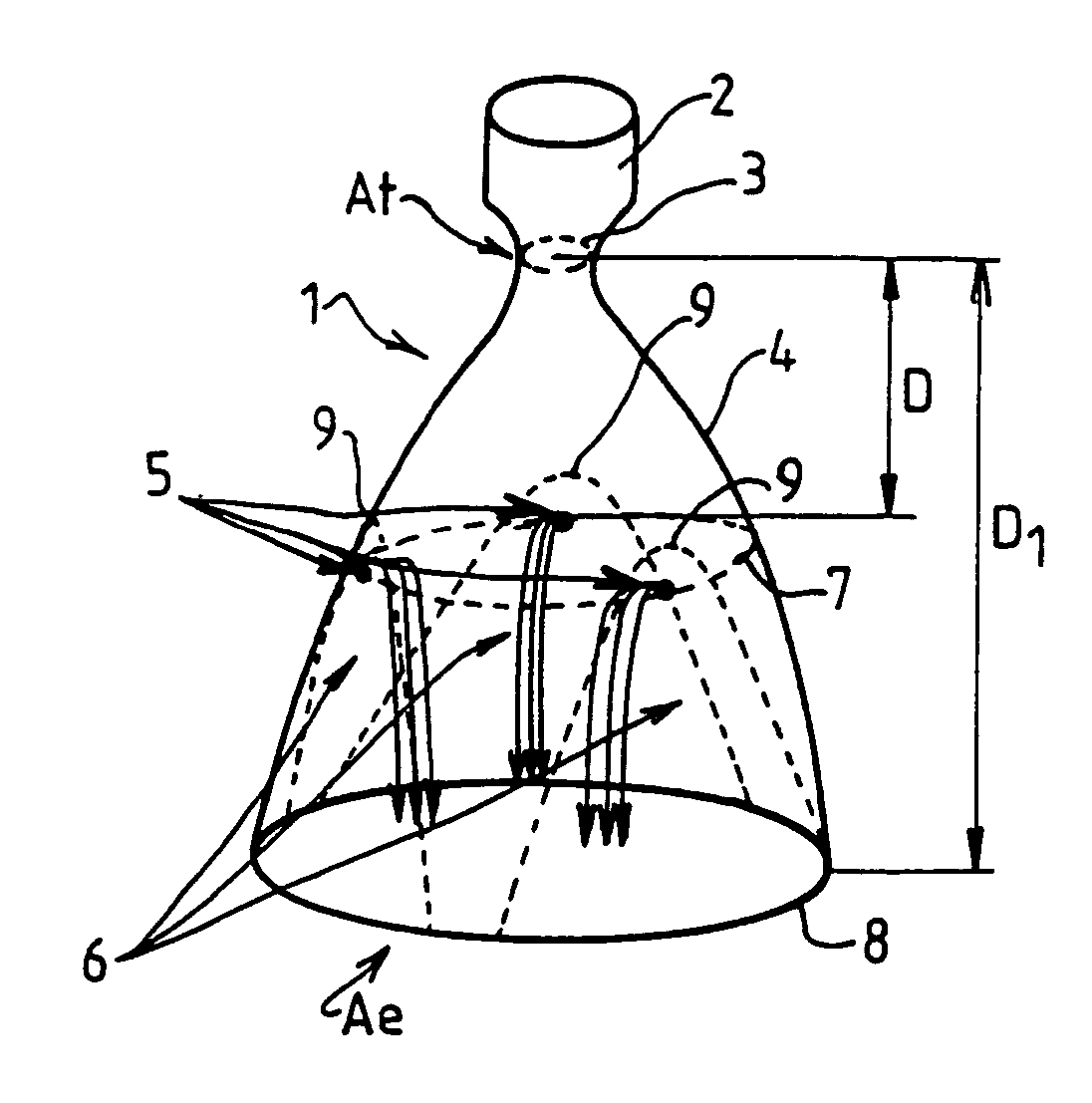

[0044]As shown in FIG. 1, a nozzle, designated by the general label 1, exhibits a combustion chamber 2, a throat 3, and a divergent nozzle body 4 which terminates in an exit cross section 8.

[0045]Over the perimeter of the divergent portion 4 of the nozzle, and in a cross section 7 situated in a plane, perpendicular to the axis of the nozzle, where the static pressure P of the jet is substantially greater than the nozzle separation pressure Psep, are arranged injection orifices 5 able to direct radially inward a jet of a fluid, for example the combustion gases originating from the turbopumps of the engine.

[0046]The flow separation which is generated by these orifices 5, does not exhibit axial symmetry, but on the contrary it is three-dimensional. This is because each of the injection points 5, represented here as three in number and distributed uniformly at 120° around the contour of the body 4 of the nozzle, induces a region of separation 6 of the stream exiting the nozzle. Owing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com