Fuel vapor storage and recovery apparatus with heat exchanger

a technology of heat exchanger and fuel vapour, which is applied in the direction of mechanical equipment, combustion air/fuel air treatment, machines/engines, etc., can solve the problems of presenting bad adsorption performance, and achieve the effect of reducing the temperature of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

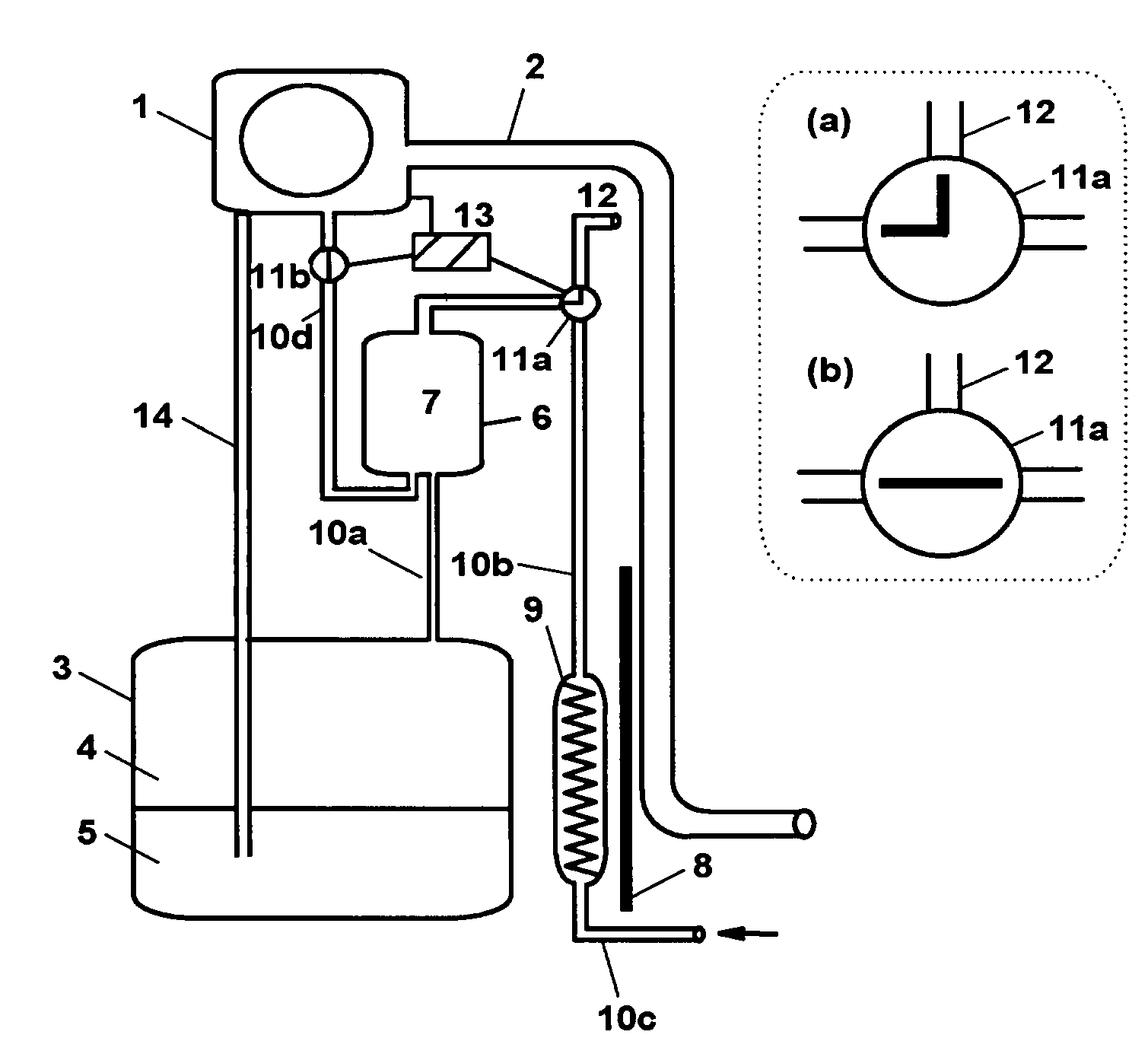

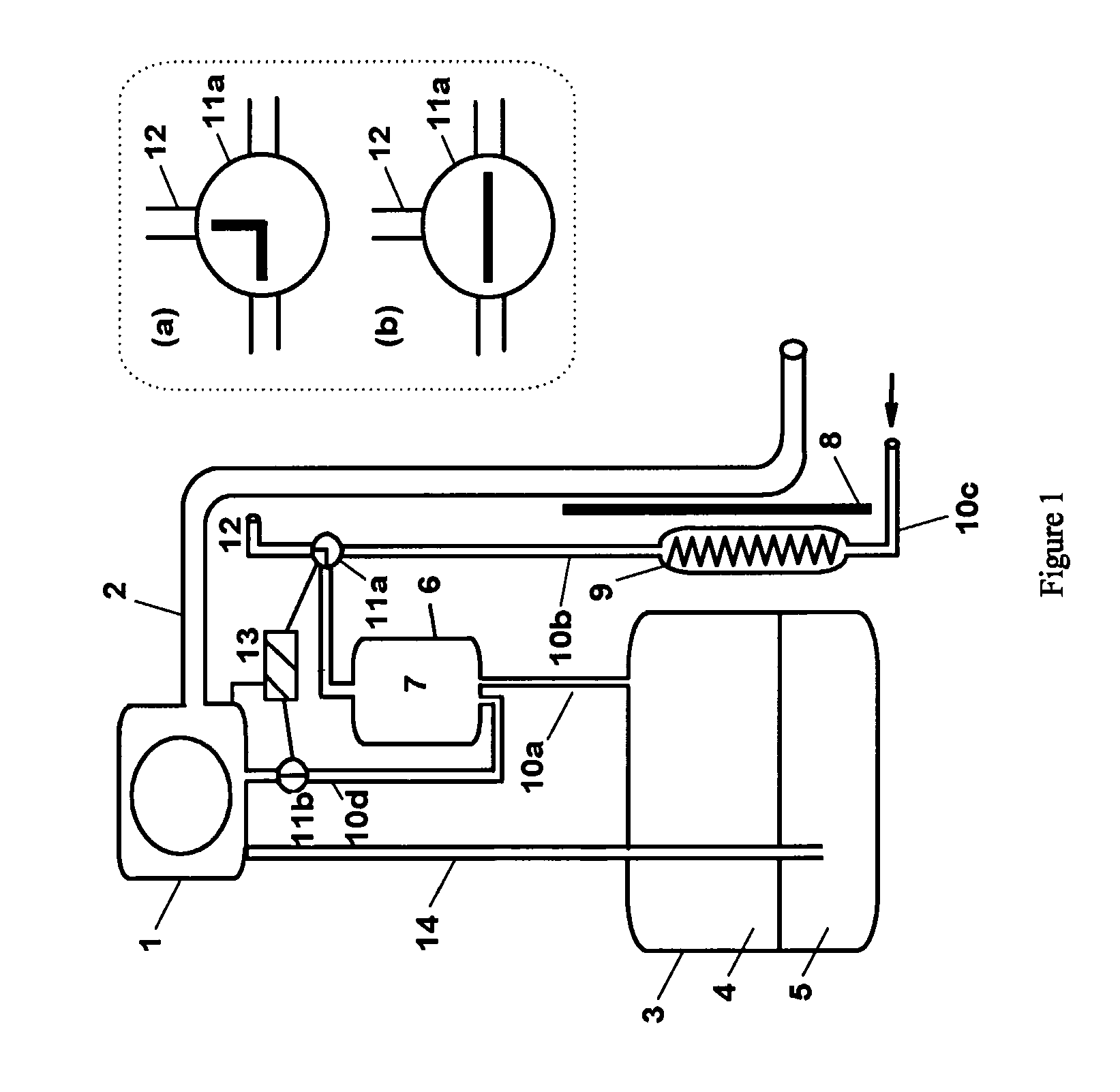

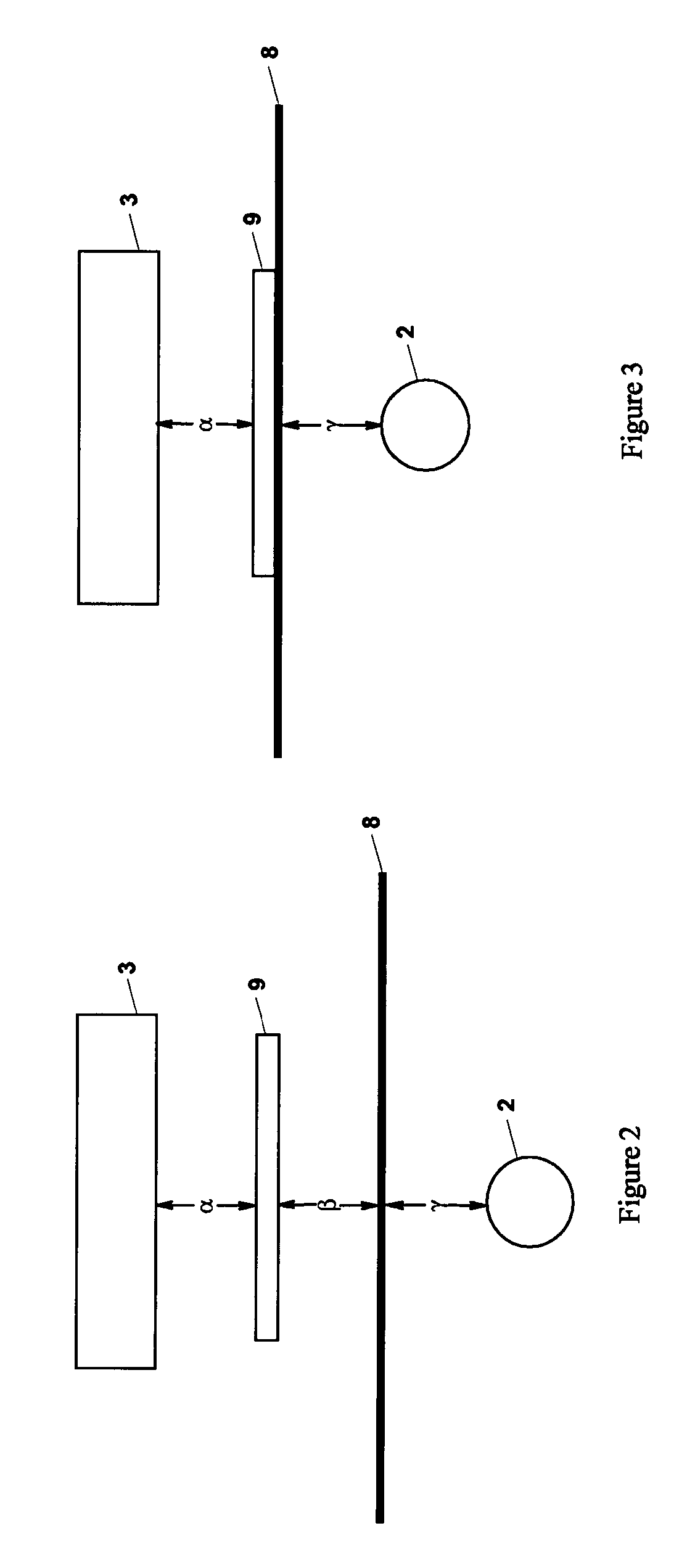

[0034]FIG. 1 shows a schematic view of a preferred embodiment of the evaporative emission control system of the invention. A motor vehicle, not shown, includes a fuel tank (3) having a variable volume of liquid fuel (5) therein, e.g. gasoline and / or methanol and a variable volume of fuel vapour / air mixture (4) above the liquid fuel (5). Liquid fuel (5) is delivered from the fuel tank (3) to an internal combustion engine (1) or a fuel processor of a fuel cell through a fuel delivery pipe (14).

[0035]The system includes a vapour storage canister (6) having therein a body of fuel vapour adsorbent material (7) such as activated carbon granules. The vapour storage canister (6) communicates with the fuel tank (3) above the liquid fuel (5) therein through a vapour conduit (10a).

[0036]A first control valve (11a) communicates the vapour storage canister (6) either with the exterior of the system through an open vent port (12) (position a), or with a heat exchanger (9) through a vapour / purge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com