Catalytic thermal conversion process

A thermal conversion and catalyst technology, applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of easy coking, thermal conversion severity and low light oil yield, so as to suppress coking, increase severity and light oil yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

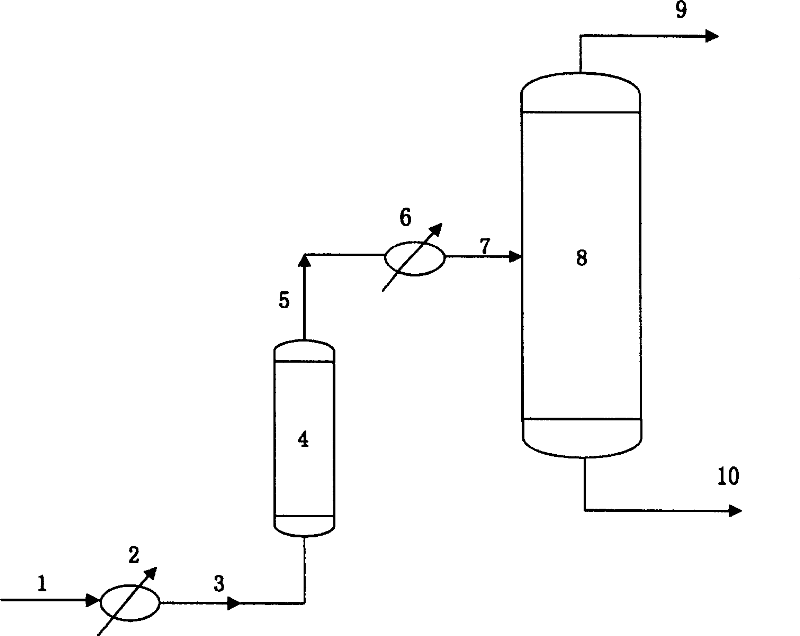

Method used

Image

Examples

Embodiment 1

[0047] Crude oil that has not been desalted and dehydrated is subjected to catalytic thermal conversion. The catalyst is AgNO 3 , wherein the content of silver ions is 10000ppm to the content of raw materials respectively. The reaction conditions are: the operating temperature is 410° C., the operating pressure is 1.0 MPa (gauge pressure), and the reaction residence time is 150 minutes. The yield of liquid is 98.5%, among which the yield of <500°C distillate is 70%. No coke is formed.

Embodiment 2

[0049] Crude oil that has not been desalted and dehydrated is subjected to catalytic thermal conversion. The catalyst is CuSO 4 ·5H 2 O, CoCl 2 ·6H 2 O, wherein the content of copper ions and cobalt ions is 5000ppm and 250ppm respectively to the content of raw materials. The reaction conditions are as follows: the operating temperature is 450° C., the operating pressure is 2.0 MPa (gauge pressure), and the reaction residence time is 200 minutes. The liquid yield is 97.5%, and the <500°C distillate yield is 75%. No coke is formed.

Embodiment 3

[0051] Crude oil that has not been desalted and dehydrated is subjected to catalytic thermal conversion. The catalyst is Ag(CH 3 COO), NiCl 2 ·6H 2 O and NaOH, wherein the contents of silver ions, nickel ions and sodium ions to the raw materials are 200ppm, 4000ppm and 4000ppm respectively. The reaction conditions are: the operating temperature is 480° C., the operating pressure is 0.2 MPa (gauge pressure), and the reaction residence time is 30 minutes. The liquid yield is 97.2%, and the <500°C distillate yield is 80%. No coke is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com