Highly bulked long-afterglow luminous material

A long afterglow luminous, high-level technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of destroying the crystal form of luminescent materials, high sintering hardness, and reducing luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

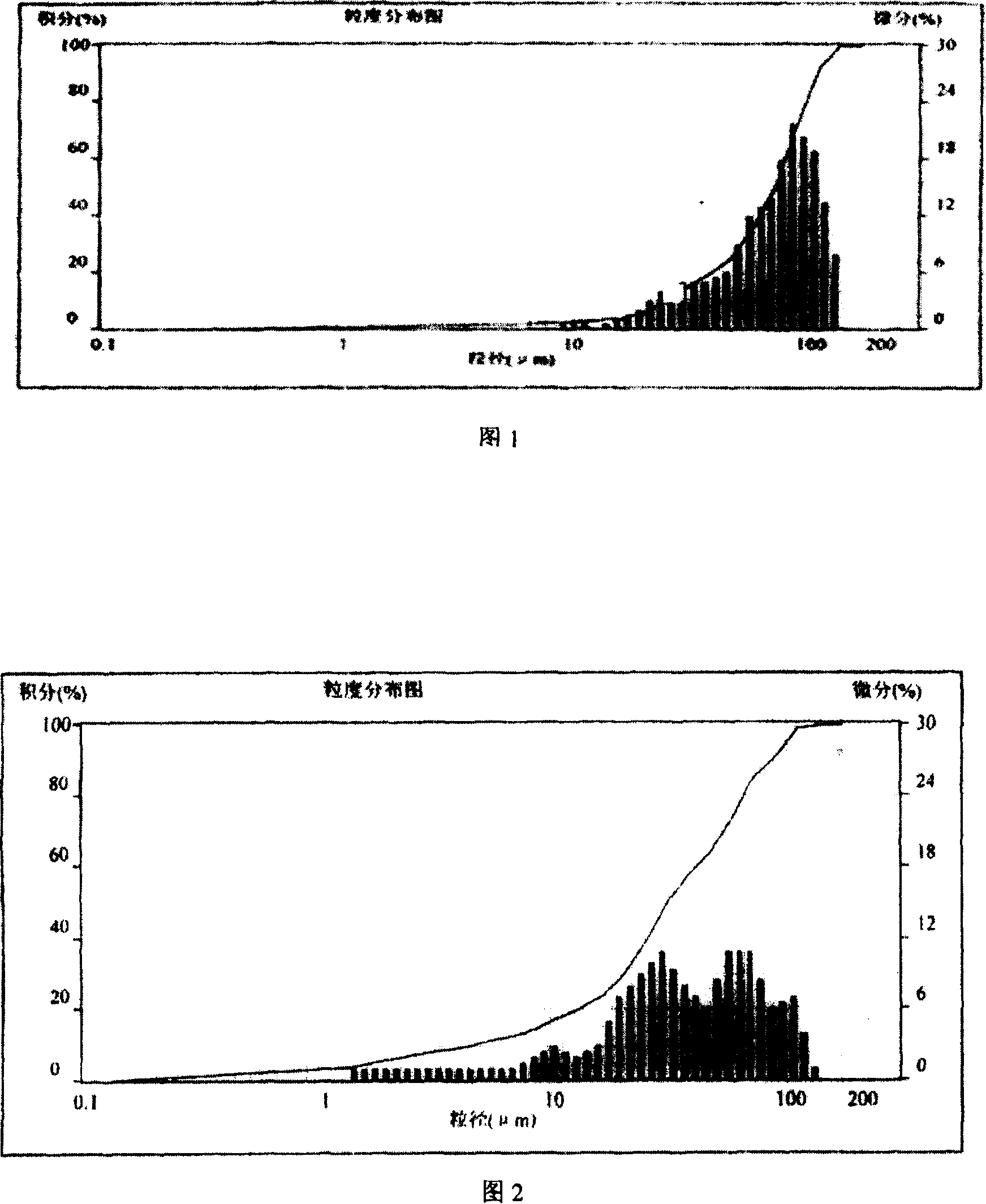

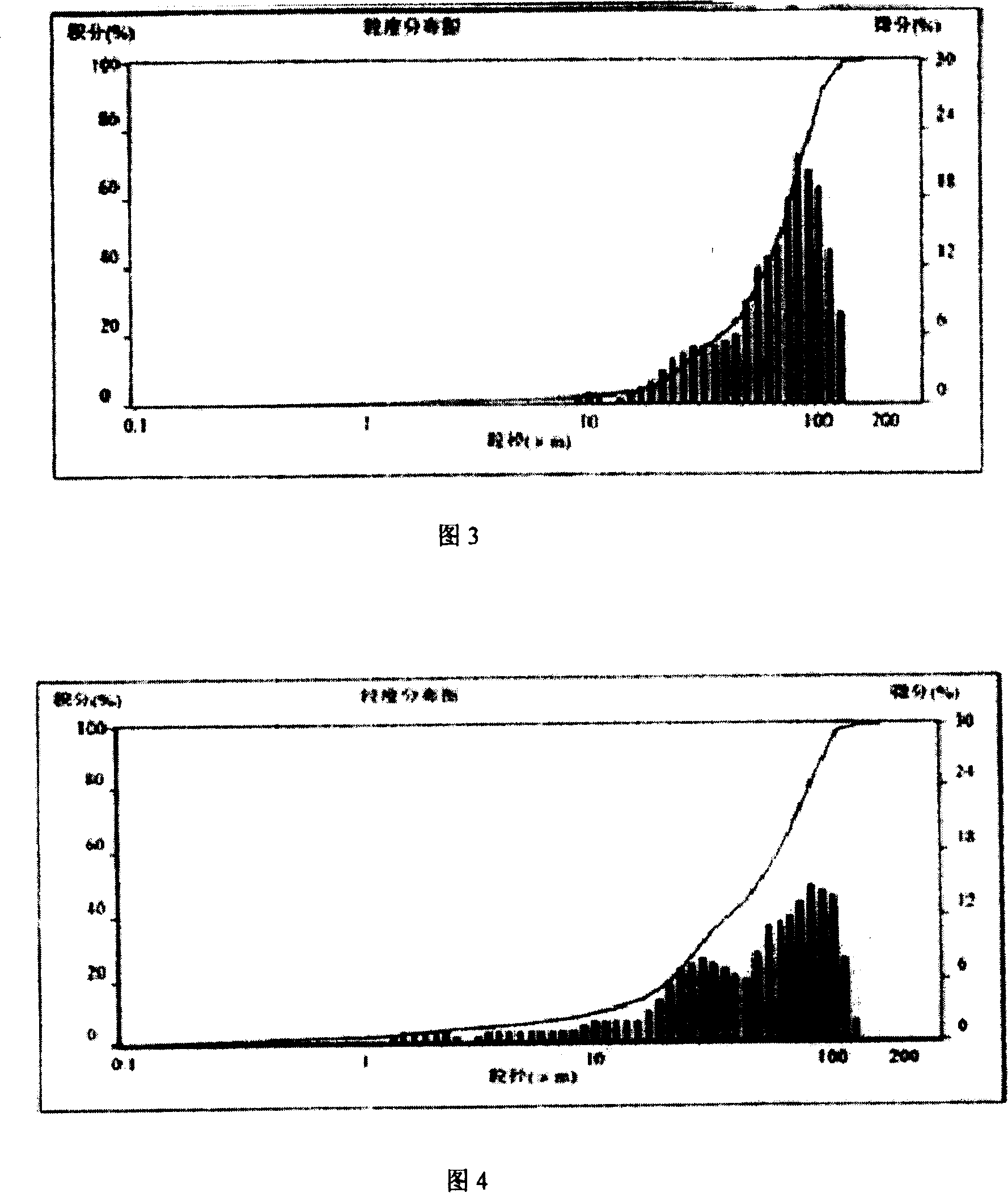

[0012] will analyze pure SrCO 3 , CaCO 3 , MgO, 99~99.99%Al 2 o 3 , 99~99.99% SiO 2 And 99.5~99.99%Eu 2 o 3 、Dy 2 o 3 , mixed according to the ratio in Table 1, mixed in a closed container for 8 hours, and then put the mixture in N 2 +H 2 Under the atmosphere, keep warm in a high-temperature furnace at 1300-1500°C for 5 hours to obtain a quicksand-like rare earth long-lasting luminescent material. Without grinding, rare earth long-lasting luminescent materials with particle sizes ranging from 30 to 200 μm can be obtained. Fig. 1, 2, 3, 4 are respectively the particle size distribution diagram of embodiment 1, 2, 6, 7.

[0013] Table 1

[0014]

serial number

Raw material composition (molar ratio)

The type and proportion of RO co-solvent

the peak

nm

μm

relative brightness

60s

Example 1

1SrCO 3 .1Al 2 o 3 .0.001MgO:

0.005Eu 2 o 3 .0.005Dy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com