Desulfurization denitration dust collecting integral purifier for coal burning boiler fume gas

A technology for desulfurization and denitrification and coal-fired boilers, which is applied in gas treatment, chemical instruments and methods, and the use of liquid separation agents, etc., to achieve the effects of low corrosion rate, low operating costs, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing.

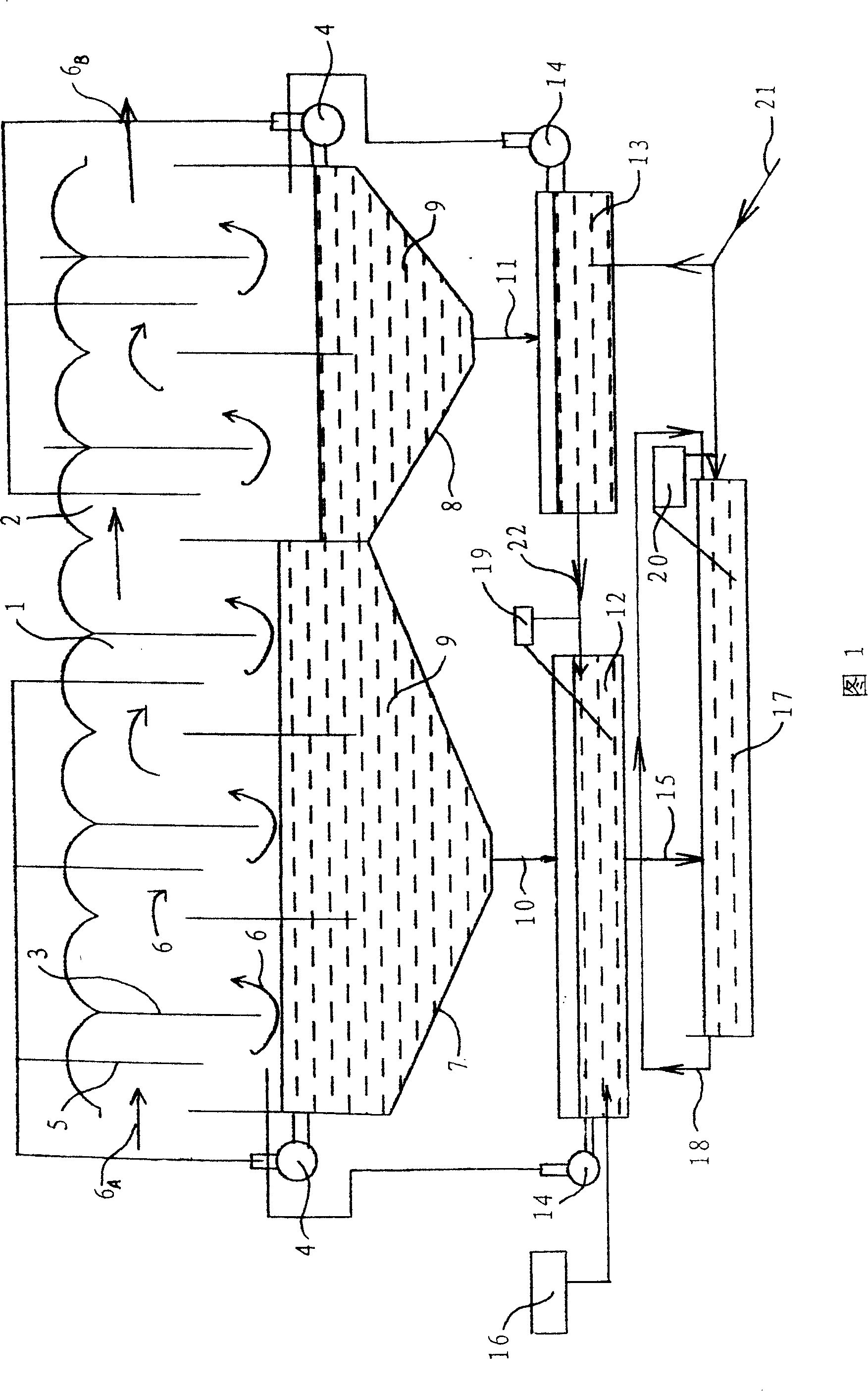

[0051] Figure 1 shows that the purification and removal reaction part is composed of the main reactor group 1 and the secondary reactor group 2. The main reactor group is composed of three reactors, and each reactor is from the top down to above the liquid level of the removal medium. Equipped with a partition plate 3, the bottoms of each reactor in the main reactor group are connected to form the main reactor to remove the medium liquid storage area 7, and the bottoms of each reactor in the secondary reactor group are also connected to form a secondary reactor group to remove The medium liquid storage area 8 contains the removal medium 9 in the removal medium liquid storage area 7 and the removal medium liquid storage area 8, and a flue gas inlet is installed in the upper part of the left space of each reactor, and a flue gas inlet is installed in the upper part of the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com