Method for the preparation of lactic acid and calcium sulphate dihydrate

A technology of calcium sulfate dihydrate and calcium sulfate hemihydrate, which is applied in the direction of carboxylate preparation, carboxylate preparation, separation/purification of carboxylic acid compounds, etc., and can solve problems such as unsuitable dihydrate crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

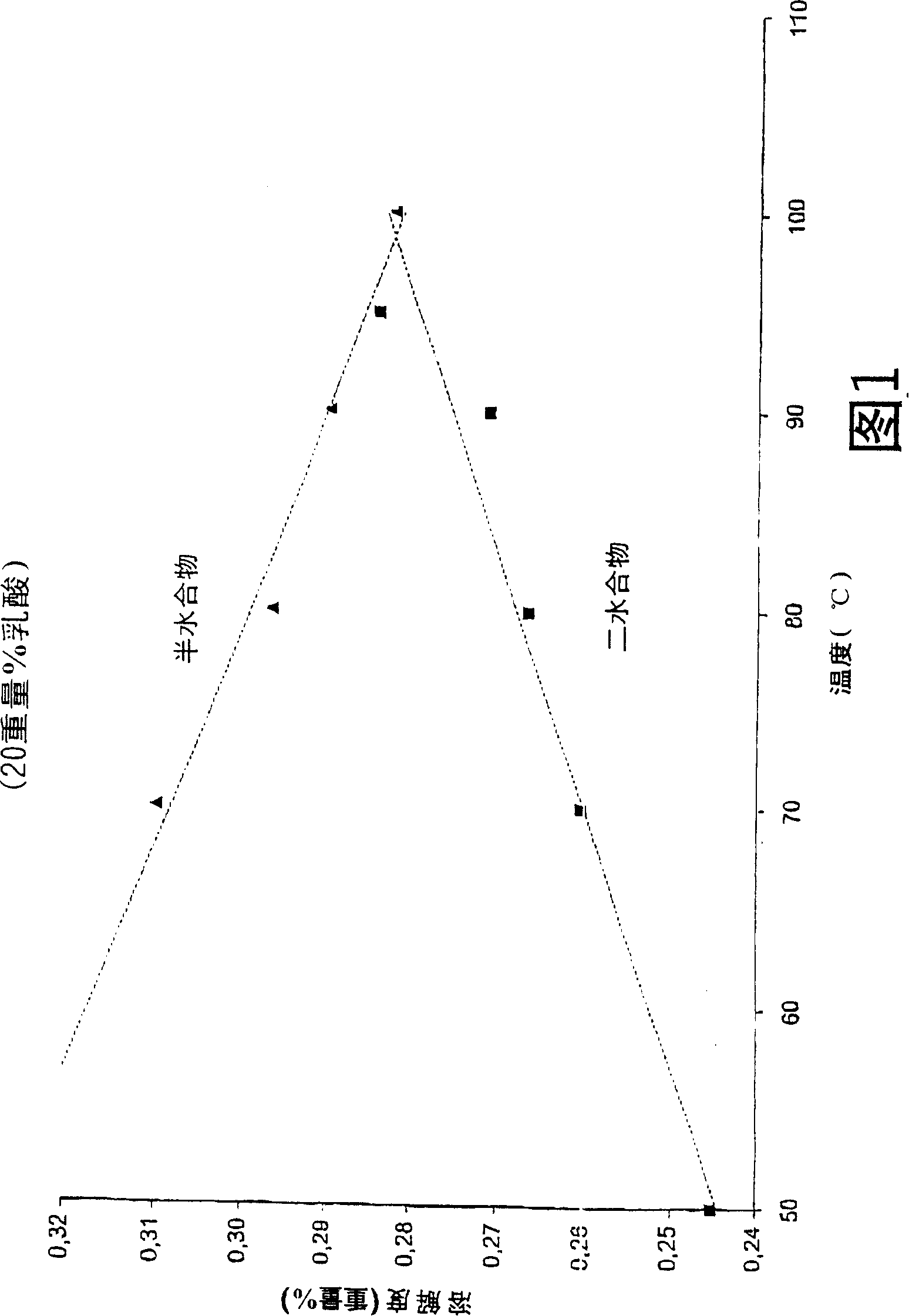

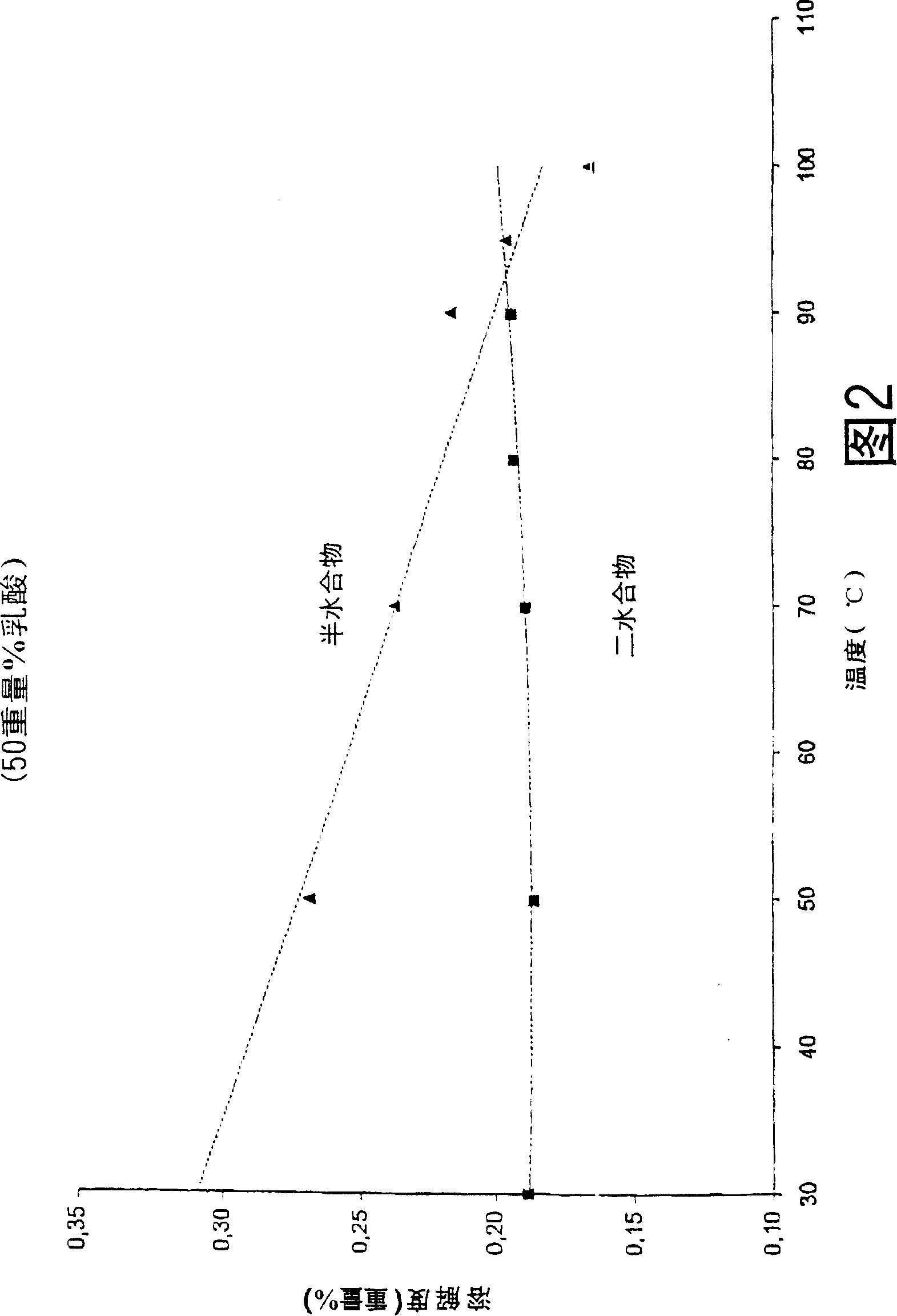

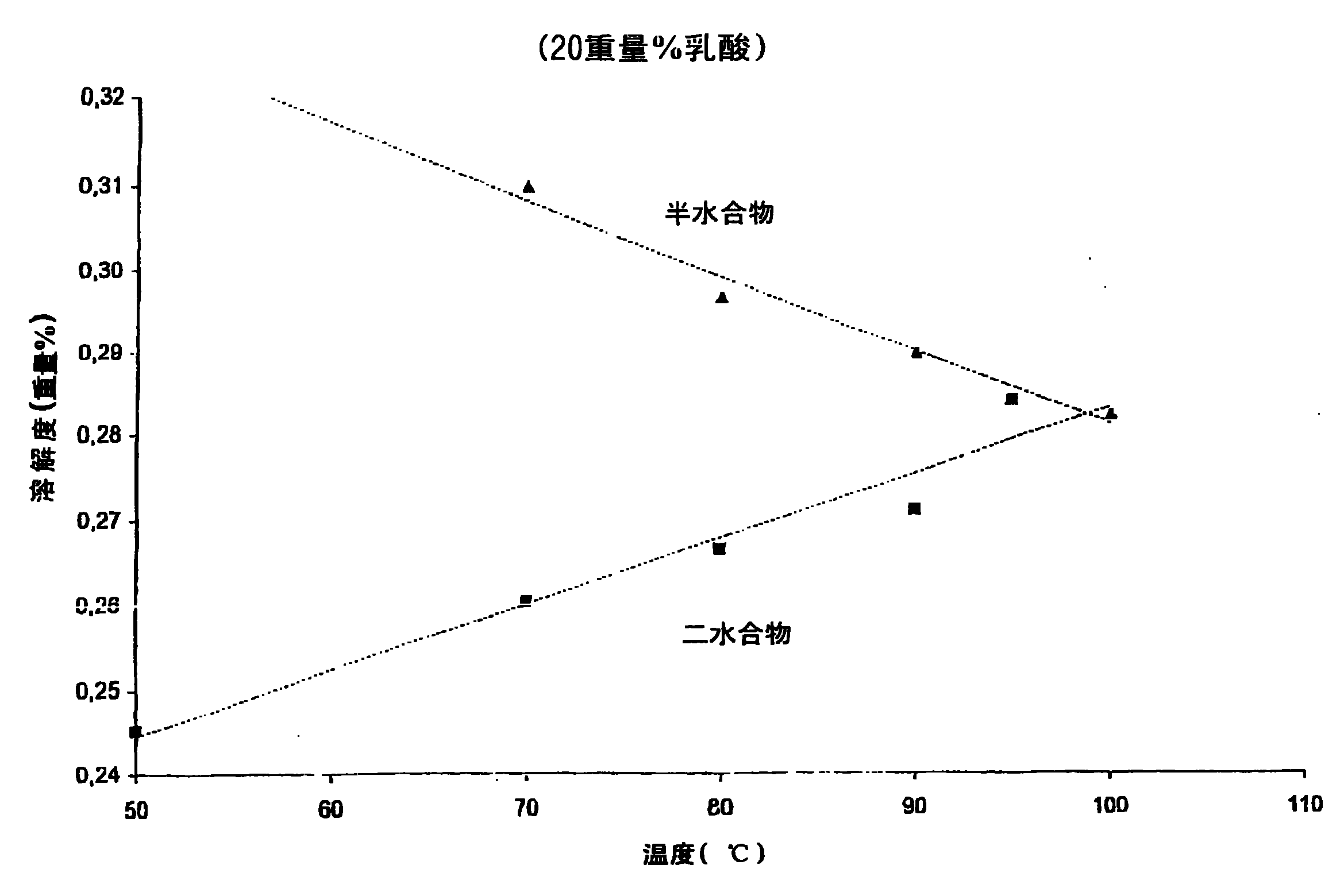

[0021] The solubility of calcium sulfate dihydrate and calcium sulfate hemihydrate was determined at each concentration as a function of temperature. A lactic acid stock solution was prepared by diluting pharmaceutical quality 90% lactic acid aqueous solution (PH90 batch number 200200003) to 20 wt% and 50 wt% respectively with water, and heating at 80° C. for 4 days. 50 ml samples of these solutions were heated at various temperatures for 30 minutes, after which 10 g of calcium sulfate dihydrate or calcium sulfate hemihydrate were added to form a suspension. Samples of 20 ml of this suspension were taken after 15 and 20 minutes and filtered through a G4 glass filter. Analyze mother liquor to determine Ca 2+ content. The filtered calcium sulfate crystals were washed twice with 20 ml of acetone and twice with 10 ml of acetone, and finally dried at 30° C. to remove residual acetone. The water of crystallization content was determined by drying the crystals at 160°C for at leas...

Embodiment 2

[0026]In a 3-liter volume double-wall reaction vessel equipped with a stirrer (stirring speed 600rpm), continuously acidify an aqueous solution containing 34.01% by weight of calcium lactate ( The solution temperature is 95°C; the flow rate is 30.57ml / min), forming more than 95.7% by weight of CaSO 4 0.5H 2 O. The reaction was controlled by measuring the conductivity (min 10.0, max 14.5 mS / cm). The residence time in the reaction vessel was about 75 minutes. The reaction mixture was then fed successively into two 5-liter double-walled crystallization vessels equipped with stirrers (crystallization vessel 1: T=80° C., stirring speed 400 rpm; crystallization vessel 2: T=80° C., stirring speed 400 rpm). The results obtained during the experiments are given in Table 2 below. Table 3 presents the analysis results of the dihydrate crystals obtained after the second step and the aqueous lactic acid solution.

[0027] Table 2 (crystallization vessel 2)

[0028] time (hou...

Embodiment 3

[0032] In a 3-liter volume double-wall reaction vessel equipped with a stirrer (stirring speed 800rpm), continuously acidify an aqueous solution containing 50% by weight of calcium lactate ( Solution temperature is 83-85°C; flow rate 28ml / min), forming more than 97.5% by weight of CaSO 4 0.5H 2 O. The reaction was controlled by measuring the conductivity (min 5.4, max 5.80 mS / cm). The residence time in the reaction vessel was about 62 minutes. The reaction mixture was then fed successively into two 5-liter double-walled crystallization vessels equipped with stirrers (crystallization vessel 1: T=62° C., stirring speed 300 rpm; crystallization vessel 2: T=60° C., stirring speed 300 rpm). The results obtained during the experiment are given in Table 4 below. Table 5 shows the analysis results of the dihydrate crystals obtained after the second crystallization and the aqueous lactic acid solution.

[0033] Table 4 (crystallization vessel 2)

[0034] time (hours)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com