Three-dimensional super-resolution confocal array scanning and micro-detecting method and device

A detection device and scanning microscopy technology, applied in the field of three-dimensional super-resolution confocal array scanning microscopy detection, can solve the problems of deviation from the ideal image point, reduced measurement accuracy, small measurement range, etc., and achieves low production cost and guaranteed measurement accuracy. , the effect of making up for the loss of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

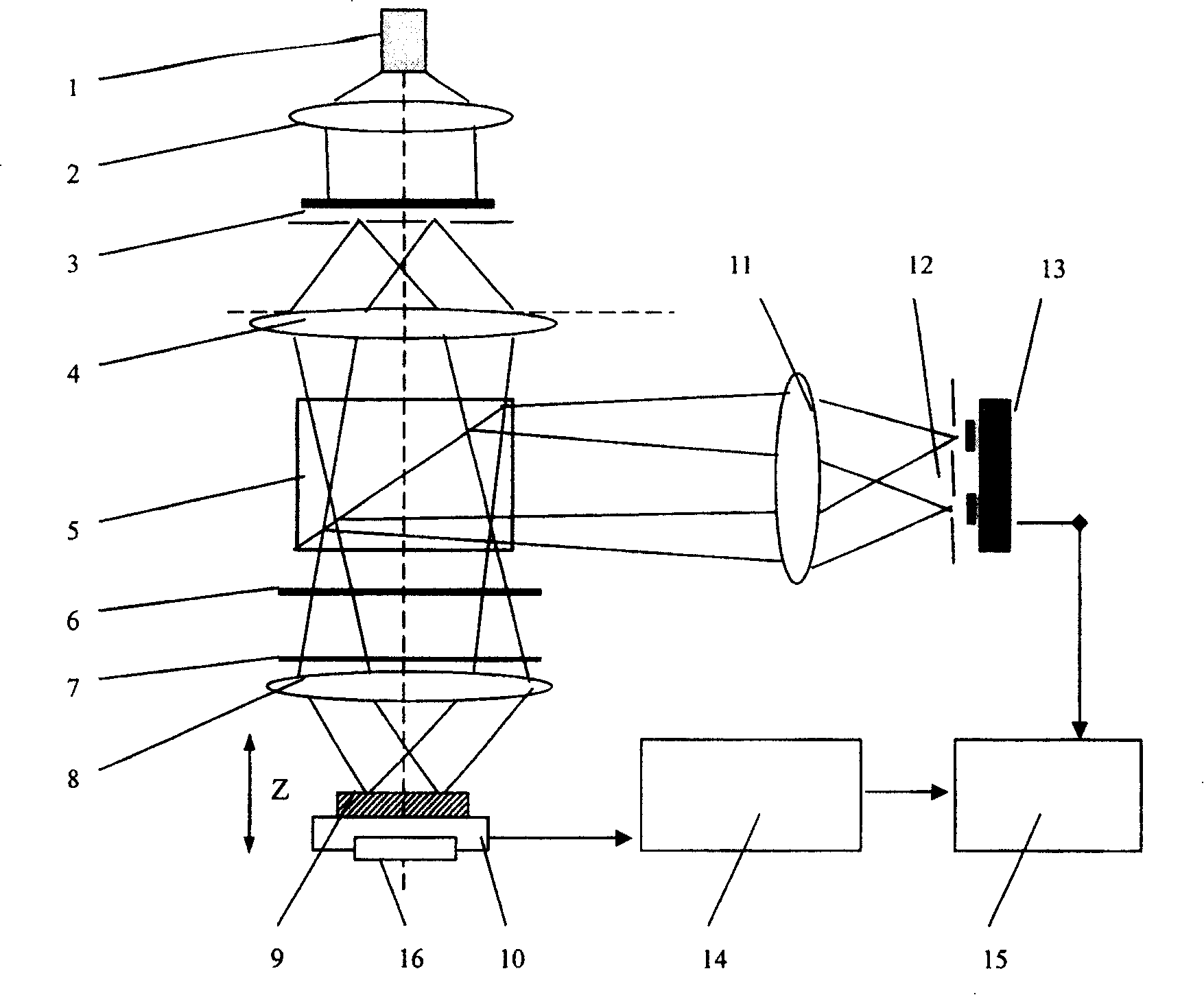

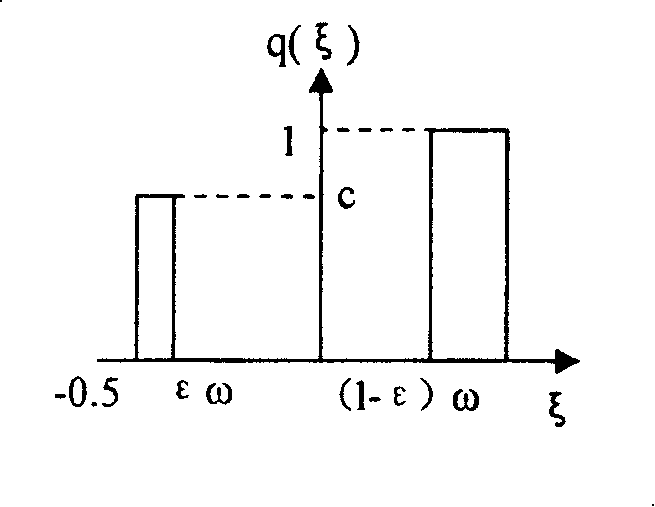

[0024] The structure of the three-dimensional super-resolution confocal array scanning microscope detection device in this embodiment is as follows figure 1 As shown, the device includes: laser 1, collimator lens 2, microlens and pinhole array 3, lens 4, polarizing beam splitter 5, 1 / 4 wave plate 6, binary pupil filter 7, microscope objective lens 8 , measured object 9, micro-displacement table 10, condenser 11, detection pinhole array 12, area array CCD13, micro-displacement drive control system 14, computer 15 and micro-displacement inductance sensor 16.

[0025] The main device models and parameters of the three-dimensional super-resolution confocal array scanning microscopic detection method and device in this embodiment are as follows:

[0026] In this embodiment, the measuring objective lens 8 is selected as the plan achromat microscope objective lens of 40×0.65 and 60×0.85. The microlens array is: 40×40 units, the unit pitch is 150um, the focal length is 4mm, and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com