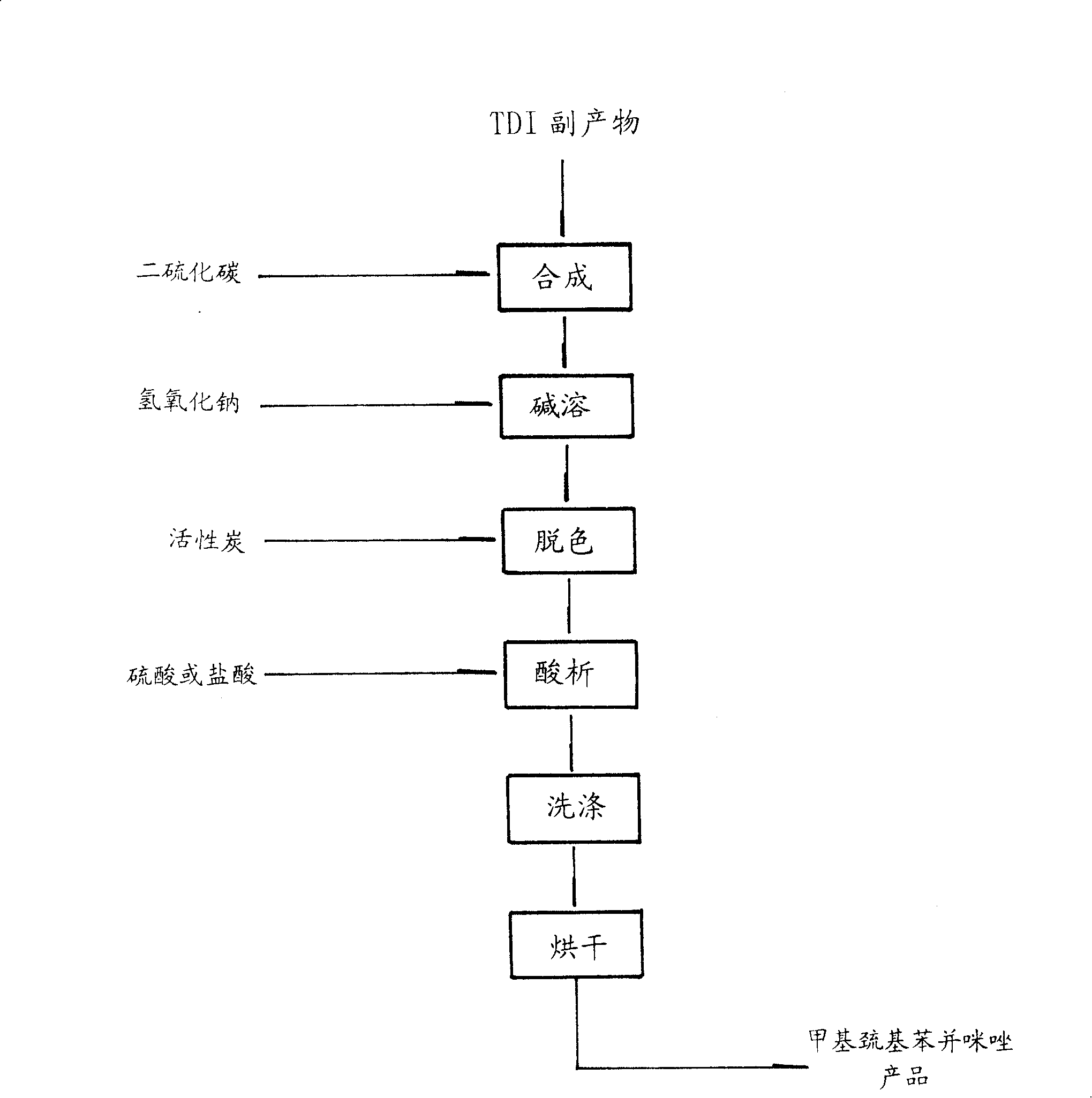

Process for synthesizing methyl mercapto benizmidazole by using TDI byproducts

A technology of methylmercaptobenzimidazole and by-products is applied in the field of chemistry to achieve the effects of good product quality, promotion of comprehensive development and utilization, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

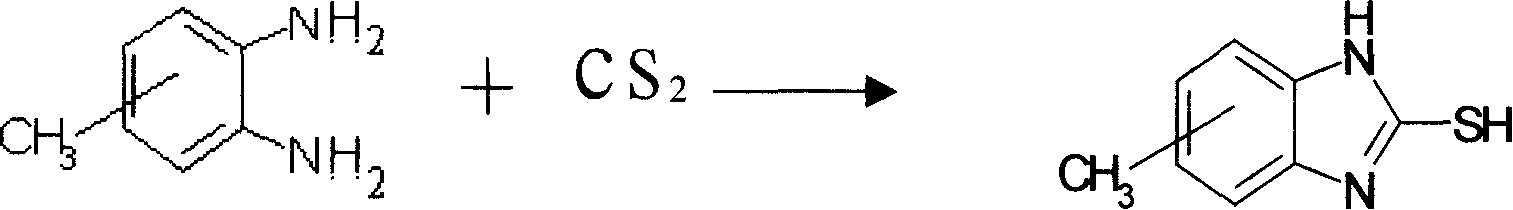

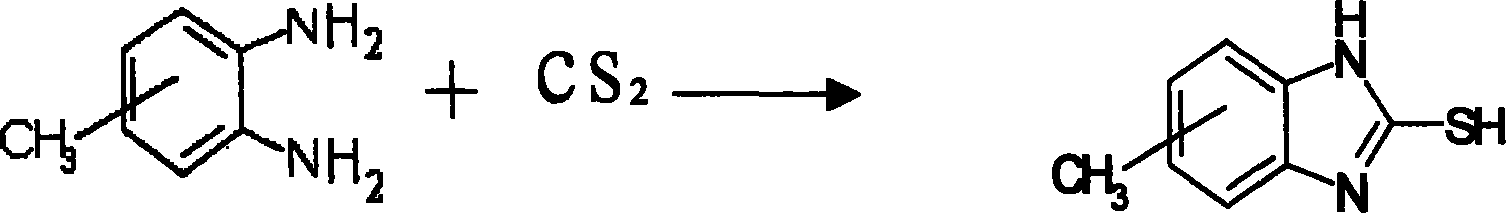

[0012] Example 1: 1000L reactor with a condenser, add 350L water in the reactor, and heat it into hot water at 70°C, hydrogenate 65 kg of TDI by-product with a content of 83.6% of methyl-o-phenylenediamine Add the organic residue into the hot water in the reaction kettle. After it is completely dissolved, slowly add 40L of carbon disulfide contained in the metering tank into the kettle according to the molar ratio of methyl o-phenylenediamine and carbon disulfide as 1:1.5, and control the condenser Reflux can be seen in the middle, after the addition of carbon disulfide, the temperature is raised to 100°C, and the reaction is completed at a constant temperature for 2 hours. The crude product of methylmercaptobenzimidazole is dissolved in sodium hydroxide solution, decolorized by activated carbon, precipitated by sulfuric acid, washed, filtered, and dried Dried and pulverized, 71.28 kilograms (97.68 percent of recovery) of product methylmercaptobenzimidazole of the present inven...

example 2

[0013] Example 2: In the 1000L reactor of the condenser, add 400L of water, heat to 75°C, add 80 kilograms of methyl o-phenylenediamine weighed to the hydrogenated organic residue of 96.8% TDI by-product hydrogenation in the hot water of the reactor, After completely dissolving, according to the molar ratio of methyl o-phenylenediamine and carbon disulfide as 1:1.4, slowly add 54L of carbon disulfide contained in the metering tank into the kettle, and control the visible reflux in the condenser. After adding carbon disulfide, raise the temperature To 90 ° C, constant temperature reaction for 3 hours to complete the reaction, the crude product of methylmercaptobenzimidazole produced by the reaction is dissolved in sodium hydroxide solution, activated carbon is decolorized, hydrochloric acid is precipitated, washed, pressure filtered, dried, and pulverized to obtain the present invention 101.02 kg of product methylmercaptobenzimidazole (97% recovery rate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com