Thermal insulation flooring

A technology for thermal insulation, floor and floor, applied in the direction of thermal insulation, floor, floor, etc., can solve the problems of poor heat supply and heat storage capacity, poor thermal insulation performance, weak temperature regulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

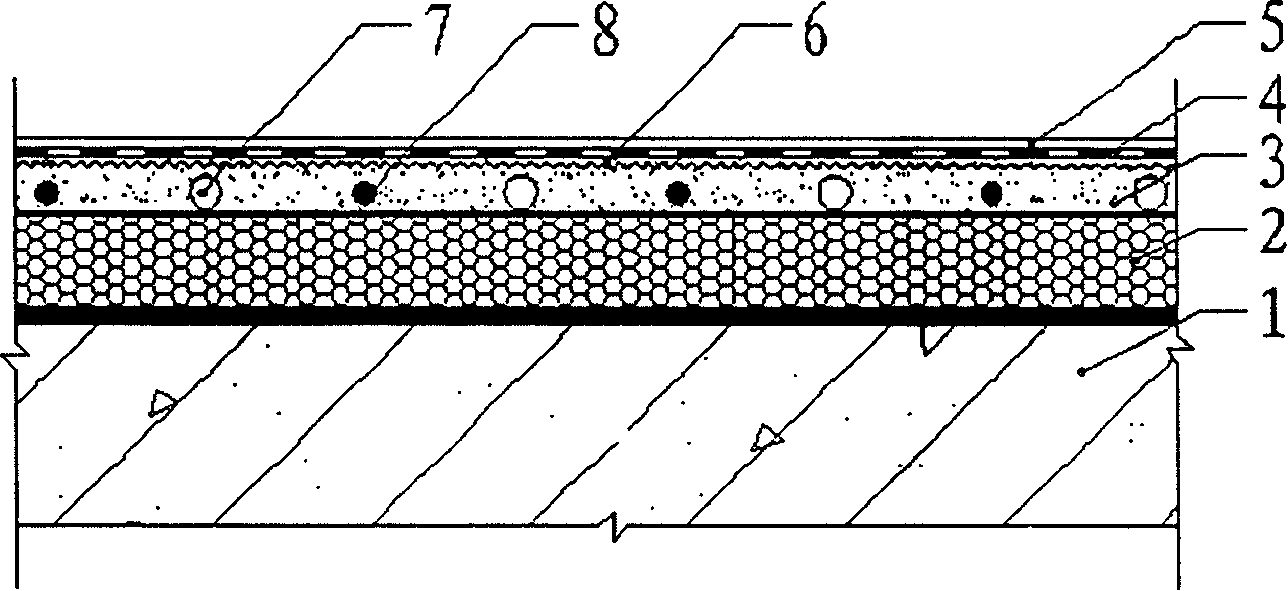

[0020] Embodiment one sees figure 1 , on the floor 1, lay an insulation layer (such as molded polystyrene board, extruded polystyrene board, polyurethane board or other insulation boards), or apply rubber powder polymer particle insulation slurry or foam concrete on the floor 1 , also can spray polyurethane; Then install heating pipe 7 and phase change pipe 8 at intervals on insulation layer 2, phase change pipe 8 is filled with phase change material, and the port of phase change pipe is sealed with sealing paste, heating pipe 7 Connect solar hot water pipes, geothermal pipes or other heating pipes. The distance between the heating pipes is generally 10 times the diameter of the heating pipes (adjusted according to actual needs), and the phase change pipe is installed in the middle of the two heating pipes; After the pipeline is completed, level it with light mortar and press it into the hot-dip galvanized welded wire mesh 6. The thickness of the light mortar leveling layer 3 ...

Embodiment 2

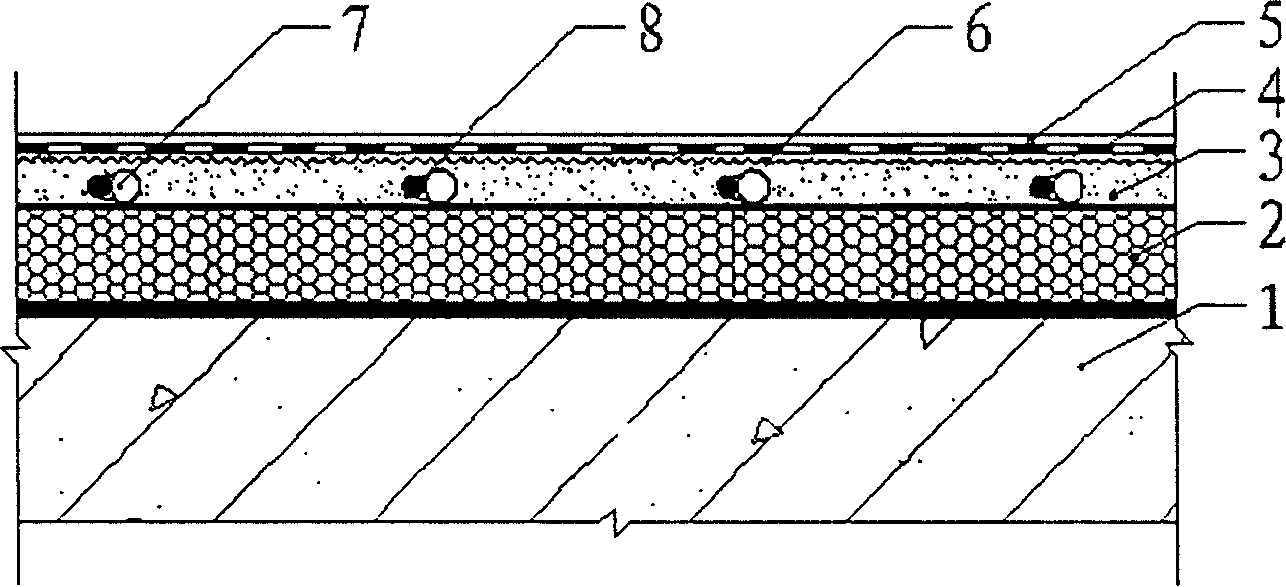

[0021] Embodiment two see figure 2 , the heating pipe 7 and the phase change pipe 8 are first bound together, and then installed in parallel at a certain interval (generally 10 times the diameter of the heating pipe).

Embodiment 3

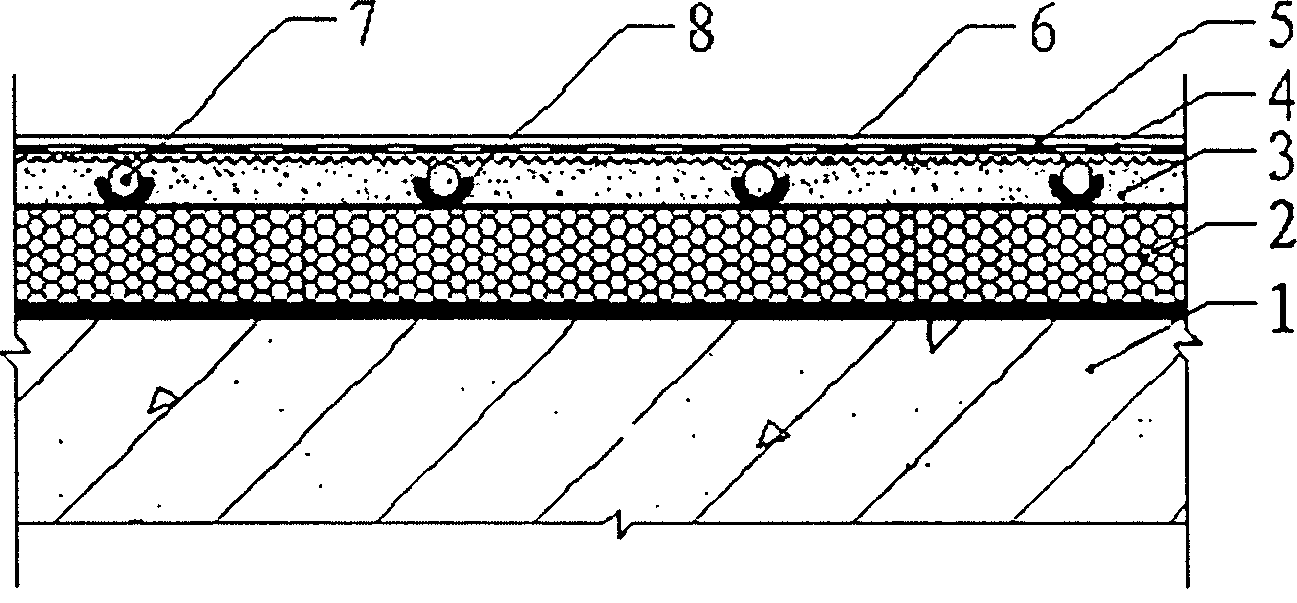

[0022] Embodiment three see image 3 , the phase change pipe 8 is a pipe with a groove, and the heating pipe 7 is installed in the groove. The distance between the heating pipe and the 29 heating pipe is generally 10 times the diameter of the heating pipe.

[0023] The phase change material in the above phase change tube can be selected from inorganic phase change materials such as hydrates of salts such as halide salts, sulfates, phosphates, nitrates, acetates, and carbonates, and organic phase change materials such as paraffin, acetic acid, and stearic acid. Phase change materials or composite phase change materials of the above two types of materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com