Method for synthesizing P-Al molecular sieve by microwave heating

A technology of phosphorus-aluminum molecular sieve and microwave heating, which is applied in molecular sieve catalysts, molecular sieves and alkali-exchanged phosphates, chemical instruments and methods, etc., can solve problems such as long crystallization time of molecular sieves, expensive organic template agents, acid-base waste liquid discharge, etc. , achieving the effects of low synthesis cost, environmental friendliness, and fast crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The synthetic method of aluminum phosphorus molecular sieve of the present invention comprises: phosphorus source, aluminum source, ionic liquid and mineralization agent make uniform reaction mixture aP 2 o 5 :Al 2 o 3 : b ionic liquid: c mineralizer (a, b, c are molar ratios in the formula) is heated up gradually under microwave radiation heating, and the reaction mixture is carried out ion thermal crystallization under a certain temperature and pressure for a certain period of time, and then filtered, washed, Drying, the specific conditions are: (1) The mixing temperature of the reaction raw materials is: 10-150°C; (2) The crystallization conditions are: at the crystallization temperature of 100-300°C, under normal pressure or autogenous pressure, the crystallization time is 1-200 Minutes; (3) in the composition of the reaction mixture, a is 0.5-10, b is 0.1-100, and c is 0.01-2.

[0018] The crystallization process of the molecular sieve in the above synthesis met...

Embodiment 1

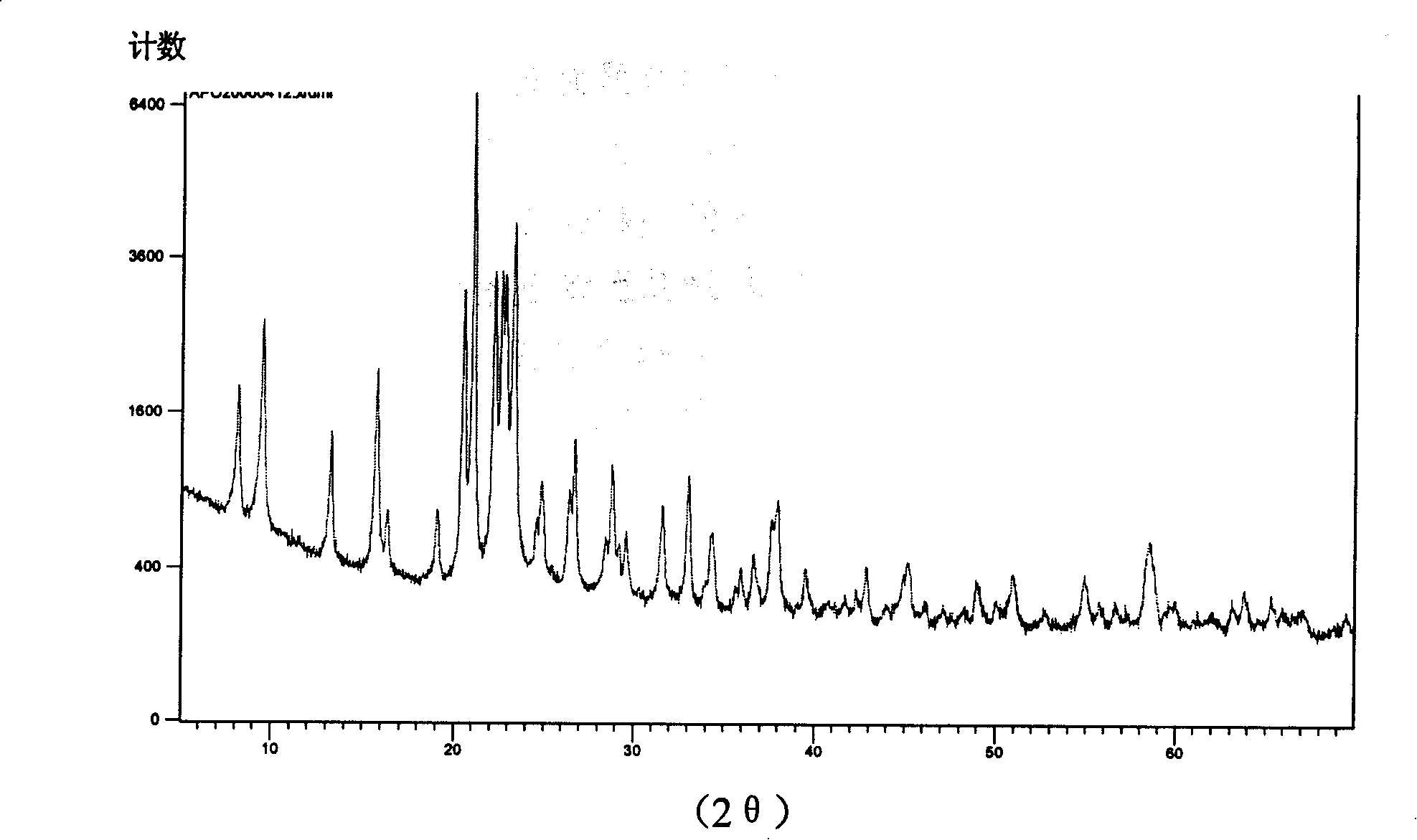

[0033]Add 1-ethyl-3-methylimidazolium bromide ionic liquid into a three-necked flask and heat up to 100°C, then add phosphoric acid and aluminum isopropoxide and mix well, then add mineralizer HF and mix well, the resulting mixture is aP 2 o 5 :Al 2 o 3 : b ionic liquid: cHF, where in molar ratio, a=3, b=40, c=0.6; the above mixture is heated to 150° C. under microwave radiation, and crystallized for 60 minutes under normal pressure or autogenous pressure; the above reaction mixture is cooled to room temperature, filter, wash the filtrate with water or an organic solvent, and dry at 100°C to obtain a powder product of aluminum phosphorus molecular sieve, which is AlPO-11 molecular sieve by XRD test.

Embodiment 2

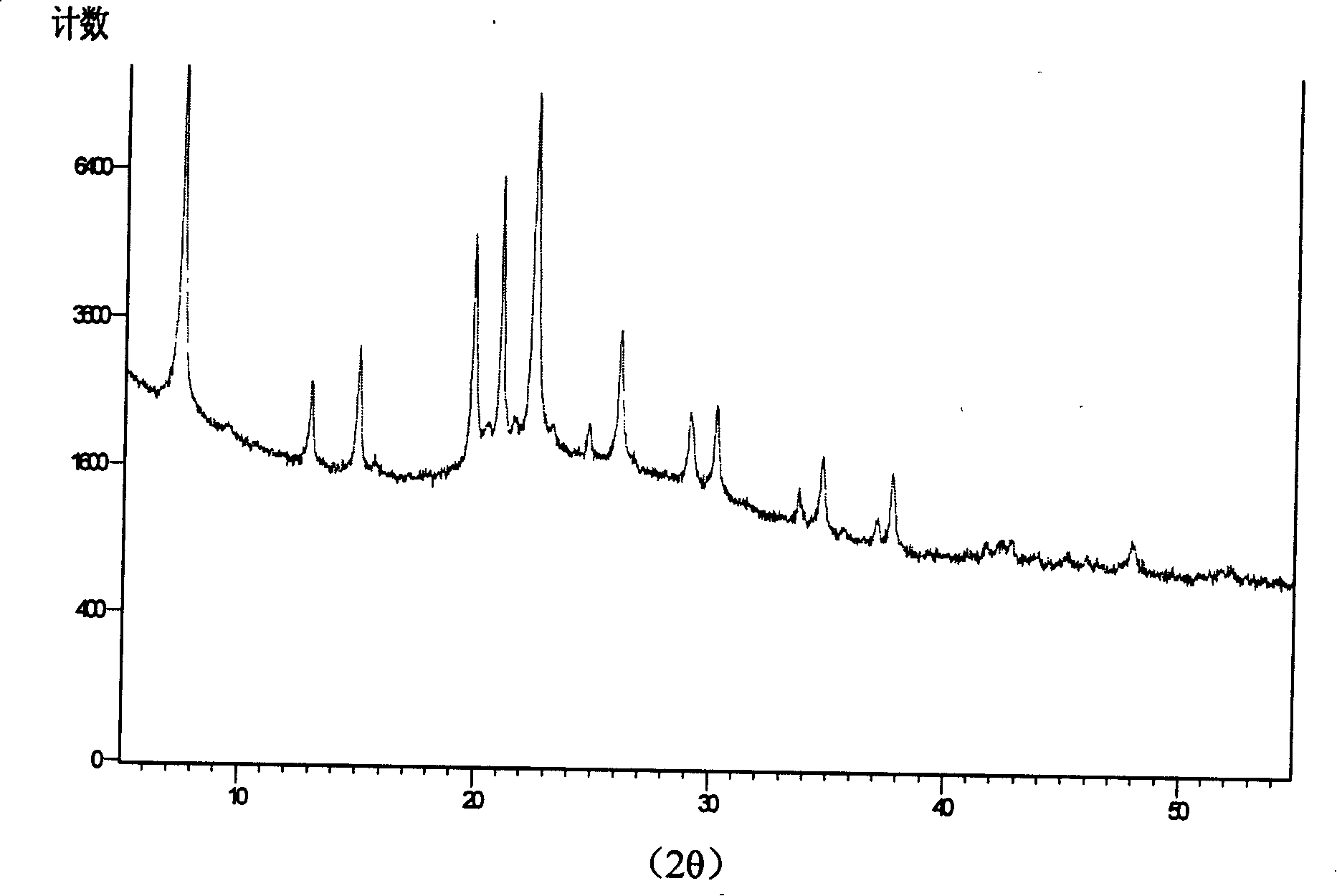

[0035] Add 1-butyl-3-methylimidazolium bromide ionic liquid into a three-necked flask and heat up to 100°C, add phosphoric acid and aluminum isopropoxide and mix well, then add mineralizer HF and mix well, the resulting mixture is aP 2 o 5 :Al 2 o 3 : b ionic liquid: cHF, where in molar ratio, a=3, b=40, c=0.6; the above mixture is heated to 150° C. under microwave radiation, and crystallized for 60 minutes under normal pressure or autogenous pressure; the above reaction mixture is cooled to room temperature, filter, wash the filtrate with water or an organic solvent, and dry at 100°C to obtain a powder product of aluminum phosphorus molecular sieve, which is AlPO-5 molecular sieve by XRD test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com