Synthesis method of key intermediate 2-cyanpyrazine of tuberculosis drug pyrazinamide

A technology of pyrazinamide and cyanopyrazine is applied in the field of synthesizing 2-cyanopyrazine, an intermediate of anti-tuberculosis drug pyrazinamide, and can solve the problems of harsh conditions, low yield, high temperature and high pressure conditions, etc. Post-processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

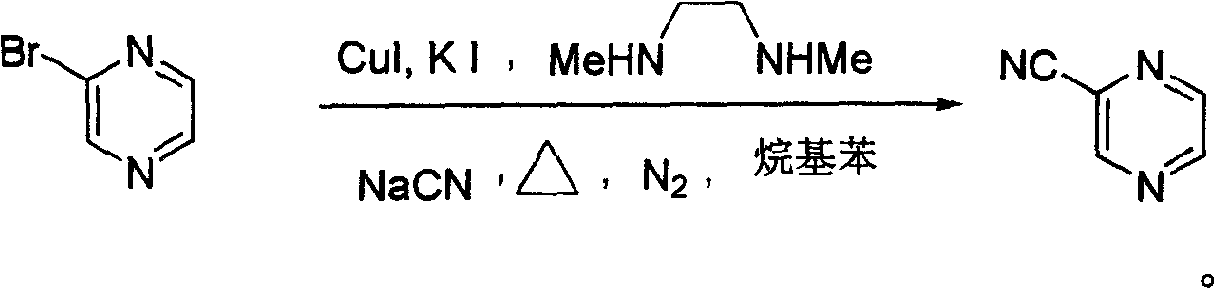

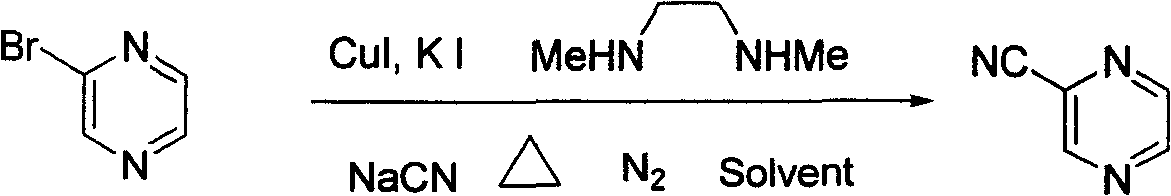

[0015] The specific reaction steps of the synthetic method of the key intermediate 2-cyanopyrazine of anti-tuberculosis drug pyrazinamide are as follows:

[0016] Alkylbenzene is used as the reaction solvent, cuprous iodide, potassium iodide and N, N'-dimethylethylenediamine are used as the combined catalyst, and 2-bromopyrazine and sodium cyanide are reacted at 100-150°C under the protection of nitrogen After 20 to 48 hours, it was filtered, and the filtrate was fractionated under reduced pressure to obtain 2-cyanopyrazine with high yield and high purity. Wherein the molar equivalent ratio of 2-bromopyrazine and sodium cyanide is 1: 1.0~2.0; The consumption of cuprous iodide is 5~30% molar equivalent of 2-bromopyrazine; 1.5-3 molar equivalents; the amount of N,N'-dimethylethylenediamine is 1-1.5 molar equivalents of 2-bromopyrazine. The recommended reaction solvent alkylbenzene is toluene, ethylbenzene, xylene, and toluene is the most preferred. The recommended response tim...

Embodiment 1

[0019] In a 1-liter three-necked flask, 500 milliliters of toluene, 48 grams (0.3 moles) of 2-bromopyrazine, 11.8 grams (0.36 moles, 1.2 equivalents) of sodium cyanide, 5.73 grams (30 millimoles, 0.1 Equivalent) cuprous iodide, 10 grams of potassium iodide (60 millimoles, 0.2 equivalents), 26.4 grams of N, N'-dimethylethylenediamine (0.3 moles, 1.0 equivalents), under nitrogen protection at 110 ° C stirring reaction for 30 Hours, the reaction was terminated, followed by filtration, and the filtrate was fractionated under reduced pressure to obtain transparent liquid 2-cyanopyrazine with a yield of 70%, a purity of 99% (GC), and a boiling point of 84-87°C (18-20mmHg).

Embodiment 2

[0021] In a 1-liter three-necked flask, 500 milliliters of ethylbenzene, 48 grams (0.3 moles) of 2-bromopyrazine, 11.8 grams (0.36 moles, 1.2 equivalents) of sodium cyanide, 5.73 grams (30 mmoles, 0.1 equivalent) cuprous iodide, 10 grams of potassium iodide (60 millimoles, 0.2 equivalents), 26.4 grams of N, N'-dimethylethylenediamine (0.3 moles, 1.0 equivalents), stirred at 120 ° C under nitrogen protection After 25 hours, the reaction was completed, followed by filtration, and the filtrate was fractionated under reduced pressure to obtain transparent liquid 2-cyanopyrazine with a yield of 73% and a purity of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com