Producing method for complementary metal oxide semiconductor image sensor

A technology of oxide semiconductors and image sensors, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., and can solve problems such as difficulty in improving NMOS transistor characteristics and complex photodiode methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

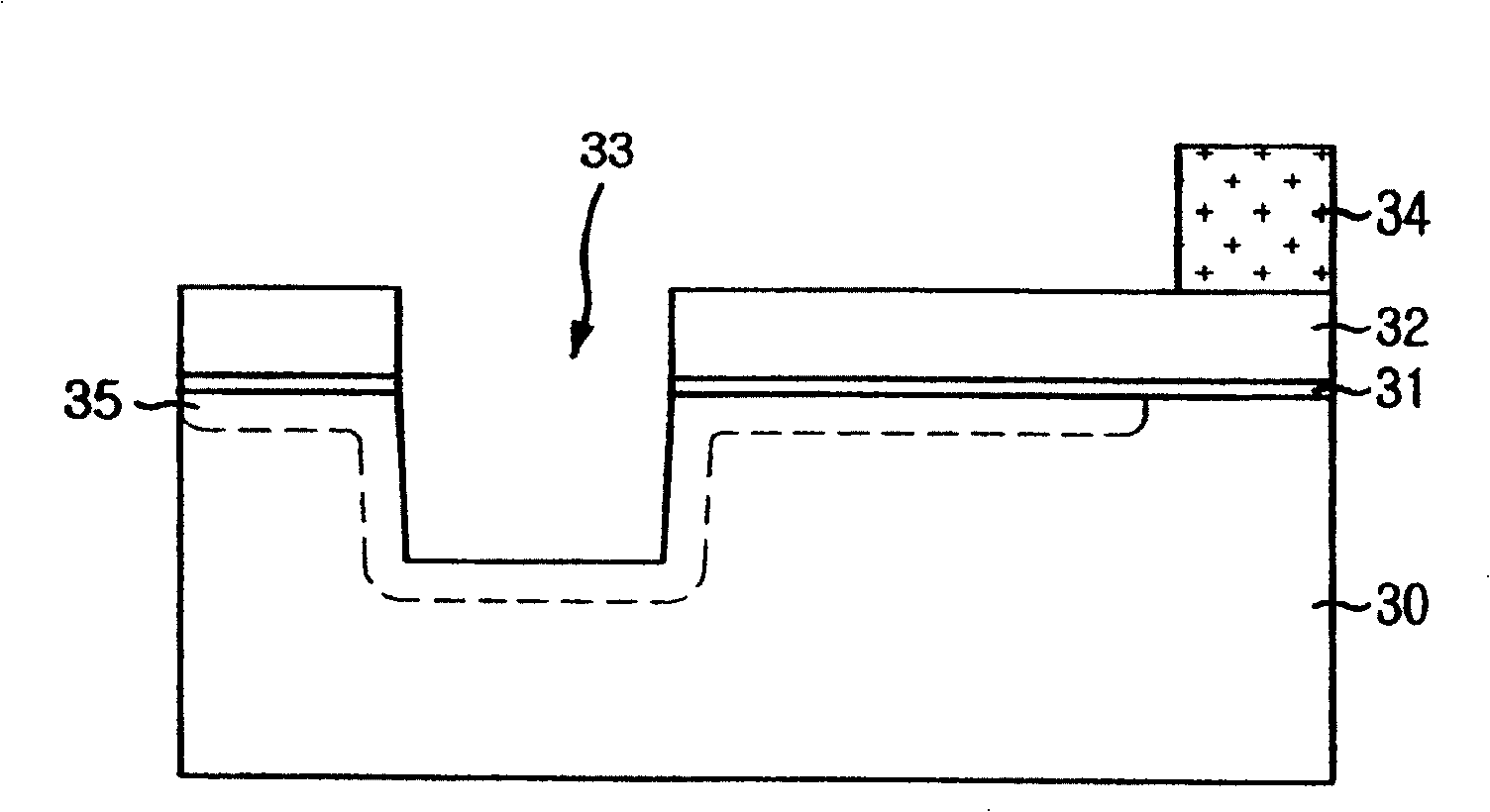

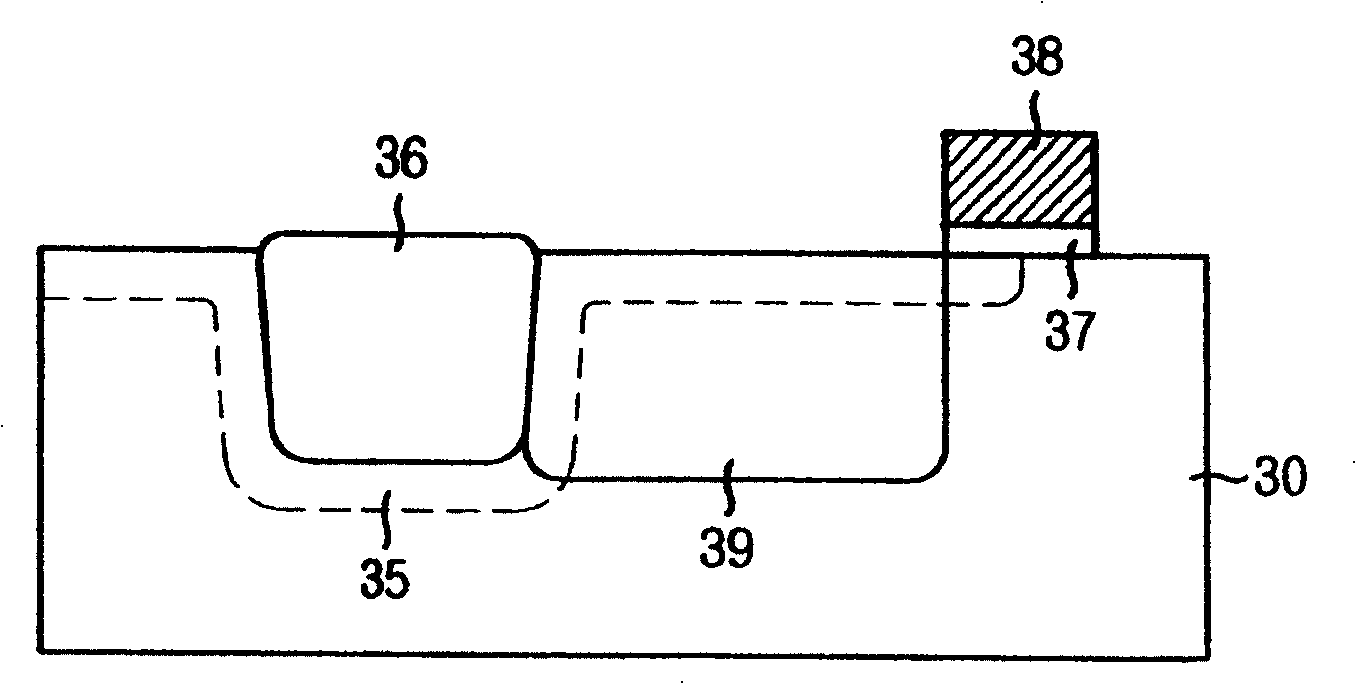

[0016] Figures 3A to 3C It is a cross-sectional view showing a method of manufacturing a CMOS image sensor according to a preferred embodiment of the present invention. Figures 3A to 3C Only a photodiode and an original transistor region are shown.

[0017] Please refer to Figure 3A , a pad oxide layer and a nitride layer are deposited on a p-type substrate 30 (providing a p-type epitaxial layer), and patterned so that a part of the p-type substrate 30 is exposed. A pad oxide layer pattern 31 and a hard mask 32 are thus formed. Here, the hard mask 32 is formed with a predetermined thickness in consideration of the channelization phenomenon occurring during a subsequent ion implantation process (for forming an N-channel stop region). Preferably, the predetermined thickness of the hard mask 32 is about to about between. Afterwards, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com