Removing water for metal oxide film or rust and using method of same removing water

An oxide film and water removal technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the adverse effects of the overall device, prevent discoloration, prevent blackening, reduce Effect of Environmental Load

Inactive Publication Date: 2009-01-14

TAKAHASHI METAL INDS

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And this will become an obstacle to coating or electroplating treatment, and will gradually peel off due to vibration, etc., and adhere to the periphery of the metal product or part. If it is a pipe, it will be mixed into the fluid and cause adverse effects on the entire device.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

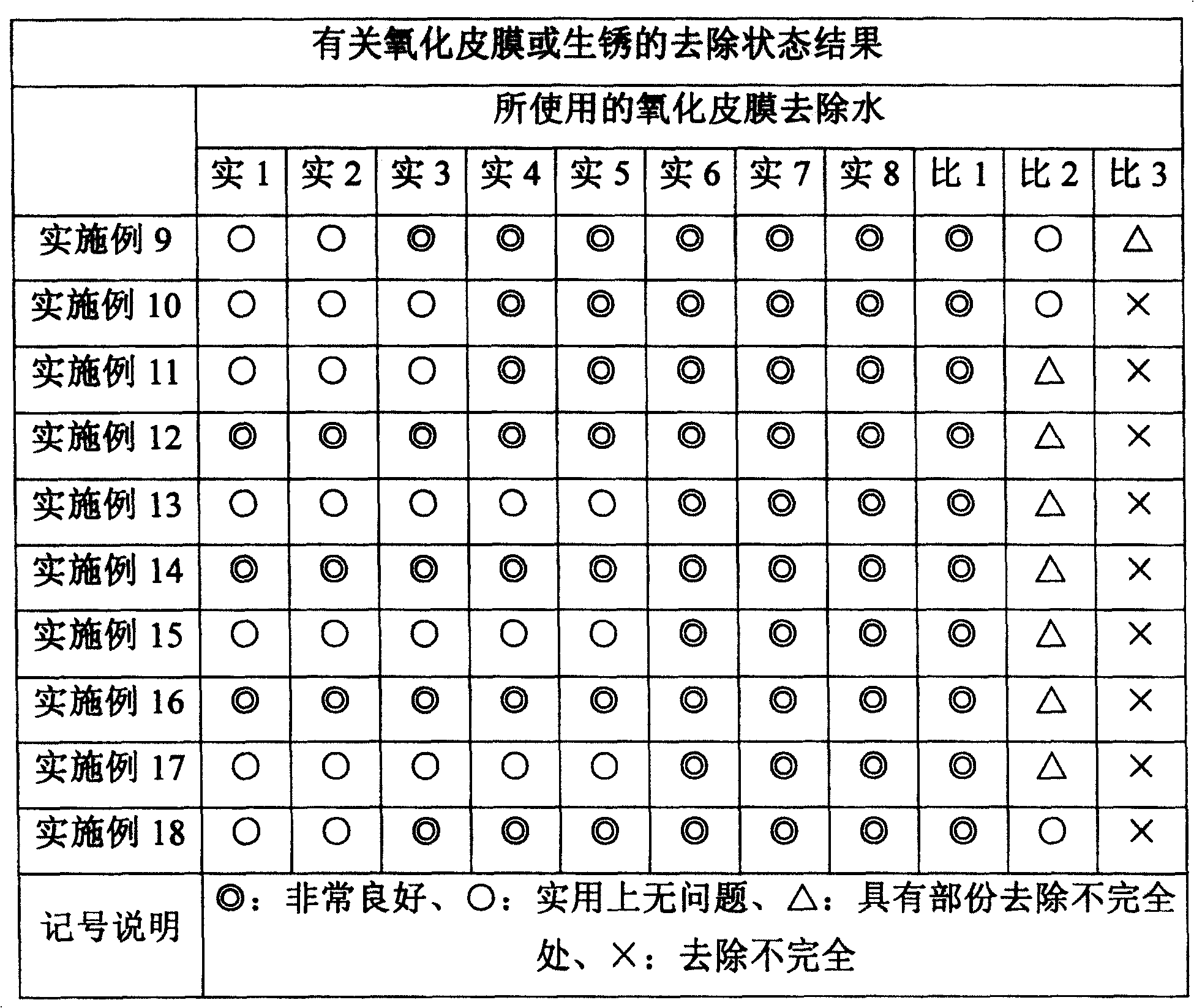

Embodiment 9

[0045] (Embodiment 9) is to place the cold-rolled steel plate (SPCC) indoors, so that the surface produces reddish-brown rust.

Embodiment 10

[0046] (Example 10) A cold-rolled steel sheet (SPCC) was heated for 10 seconds with a gas burner to form a black oxide film on the surface.

Embodiment 11

[0047] (Example 11) A stainless steel plate (SUS304) was heated for 10 seconds with a gas burner to form a dark brown oxide film on the surface.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

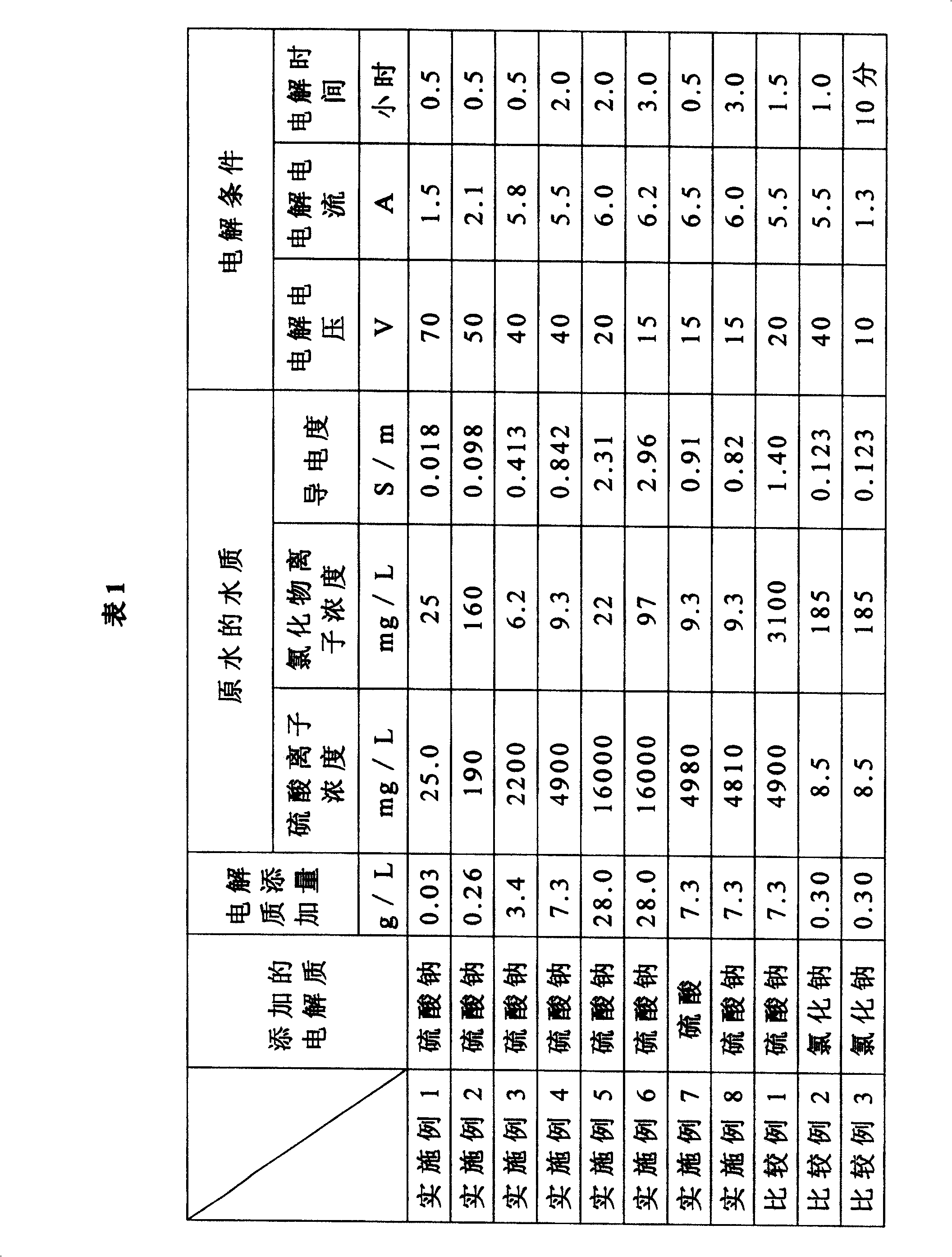

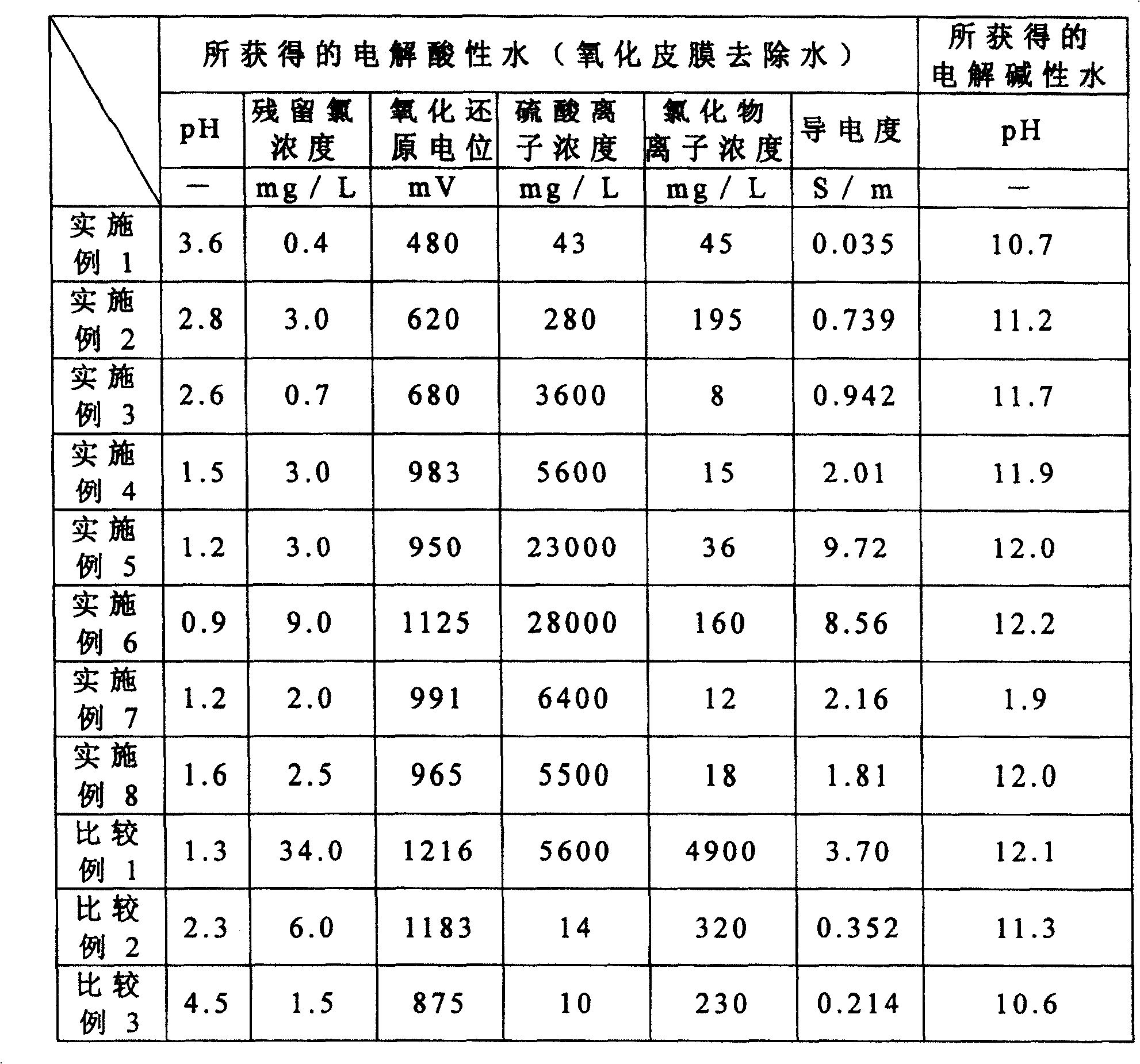

The invention provides a method for removing water for metal oxide film or rust, wherein a kind of electrolyzed acidic water composed of specific ions and prepared through electrolysis can be very effective in removing the oxidation film or rust from metals, the acidulous water can produce ultrasonic oscillation action which can fulfill the removing work with high quality and within a short period of time.

Description

technical field [0001] The present invention relates to a method for removing oxide film or rust on a metal surface using acidic water obtained by electrolysis as water for removing oxide film or rust on a metal surface, and using the acidic water. Background technique [0002] For example, when metal products (especially steel alloys, copper and copper alloys) are placed for a long time, an oxide film will be formed on the surface, resulting in the disappearance of metallic luster, discoloration, reduction of electrical properties, and reduction of material strength. Furthermore, these oxide films will cause further corrosion, and even progress to a rusted state. [0003] In addition, when metal products are subjected to heating operations involving gas welding, electric welding, spot welding, brazing, etc., an oxide film will be formed on the surface in the same way as when they are left for a long time. In addition, when the heating time is long or the heating temperatur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23G1/02C02F1/461

Inventor 中川善一西村清司广川载泰

Owner TAKAHASHI METAL INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com