Low-temperature high-strength, high-toughness steel and preparing method therefor

A high-toughness steel, high-strength technology, applied in high-toughness steel and its manufacturing, high-strength fields, can solve the problems of lack of competitiveness, high cost, overweight parts, etc., and achieve high safety requirements, low cost, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

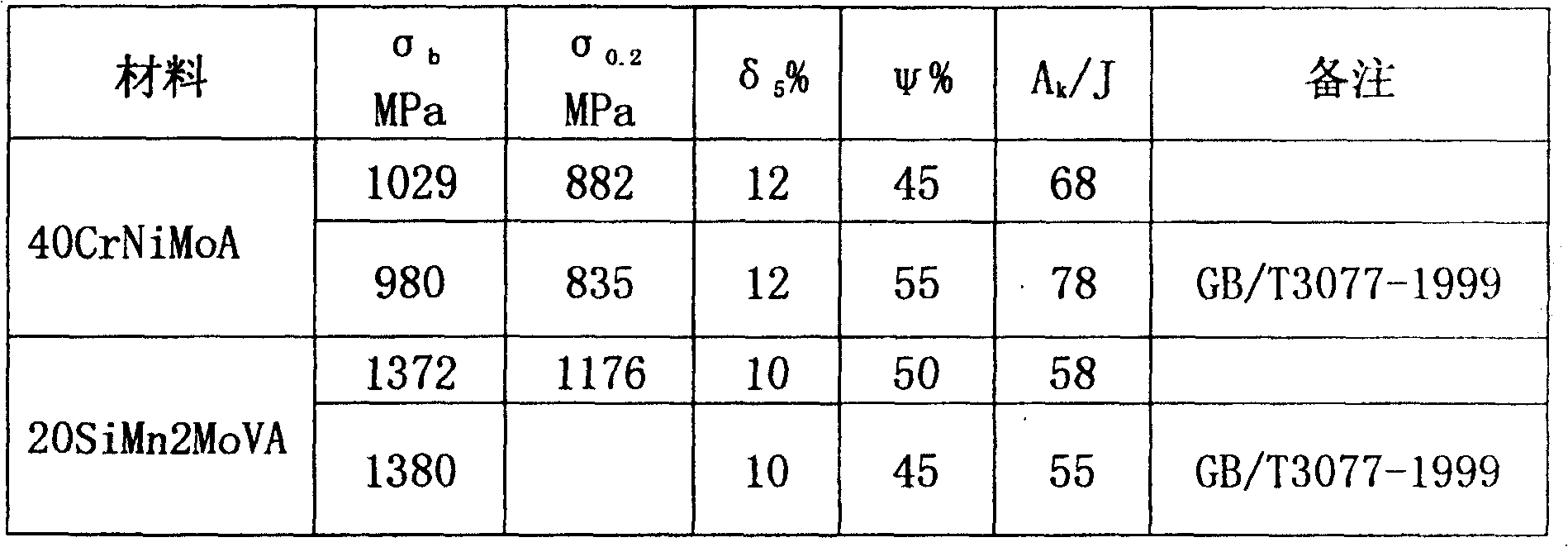

[0044] Embodiment 1: The steel used for the 150T single-arm lifting ring of the bearing part in the lifting system of petroleum drilling and repairing equipment and its manufacturing method:

[0045] Technical requirements: yield strength σ 0.2 ≥1180MPa, tensile strength σ b ≥1380Mpa, elongation δ 5 ≥10%, reduction of area ψ≥45%, V-notch impact energy Akv(-20℃)≥42J. Ultrasonic flaw detection GB / T6402-91, Class II qualified; surface magnetic particle flaw detection JB / T4730.4-2005, Class II qualified.

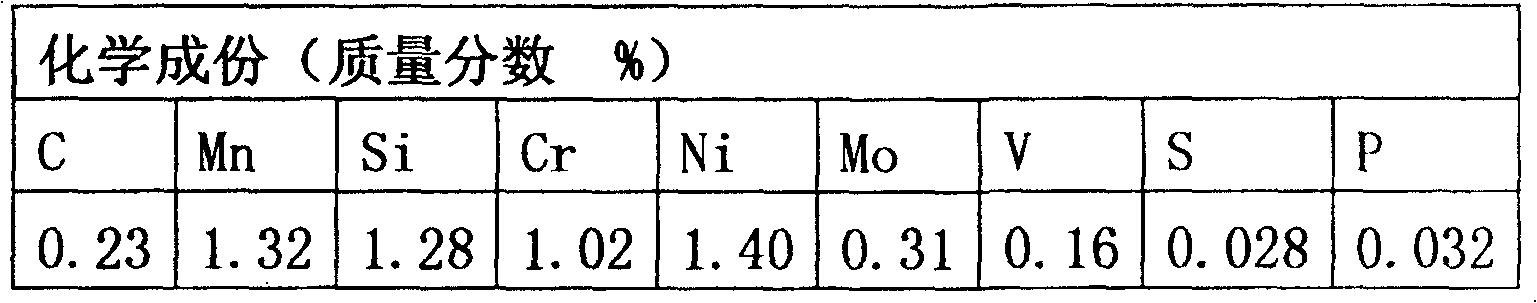

[0046] chemical composition

[0047]

[0048] The part is manufactured in the following sequence of process steps:

[0049] 1. Smelting process: 1 ton intermediate frequency induction melting furnace is used, and ceramic mesh is filtered during casting.

[0050] 2. Forging process:

[0051] Oil heating furnace: heating temperature 1300±10℃

[0052] 5 tons of electro-hydraulic hammer: initial forging temperature 1100°C, final forging temperature 870°C, post-forging anne...

Embodiment 2

[0060] Example 2: Steel for 150T single-arm lifting rings requiring a service environment temperature of -45°C and its manufacturing method:

[0061] Technical requirements: yield strength σ 0.2 ≥1180MPa, tensile strength σ b ≥1380Mpa, elongation δ 5 ≥10%, reduction of area ψ≥45%, V-notch impact energy Akv(-20℃)≥42J, Akv(-45℃)≥27J, ultrasonic testing GB / T6402-91, Class II qualified; surface magnetic particle testing JB / T4730.4-2005, Class II qualified.

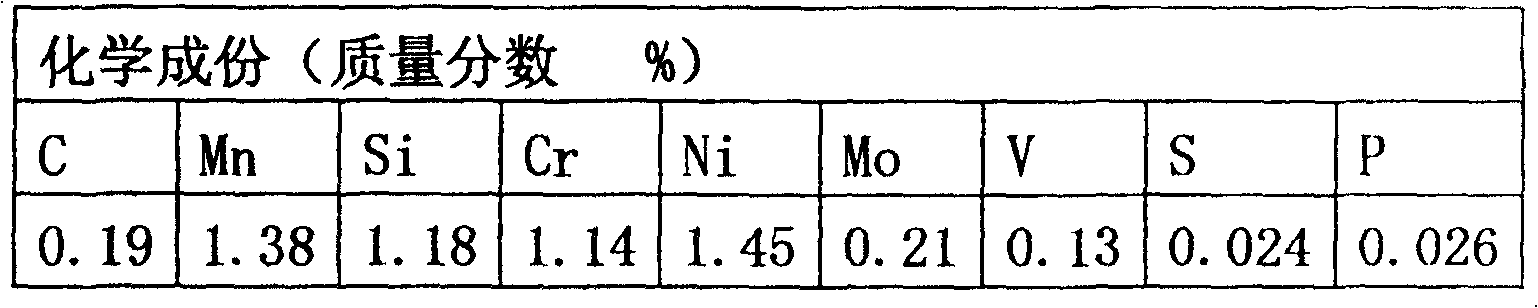

[0062] chemical composition

[0063]

[0064] The part is manufactured in the following sequence of process steps:

[0065] 1. Smelting process: 1 ton intermediate frequency induction melting furnace is used, and ceramic mesh is filtered during casting.

[0066] 2. Forging process:

[0067] Oil heating furnace: heating temperature 1290±10℃

[0068] 5 tons of electro-hydraulic hammer: initial forging temperature 1150°C, final forging temperature 870°C, post-forging annealing 700±10°C, heat preservation 2h, furnace tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com