Flux-cored wire for gas shielded arc welding

A gas shielded and arc welding technology, applied in the direction of arc welding equipment, welding medium, welding equipment, etc., can solve the problems of no improvement in moisture absorption resistance, no consideration for reducing diffusible hydrogen, poor operability and arc stability, etc., and achieve good Soldering workability, reduction of diffusible hydrogen, effect of improving moisture absorption resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

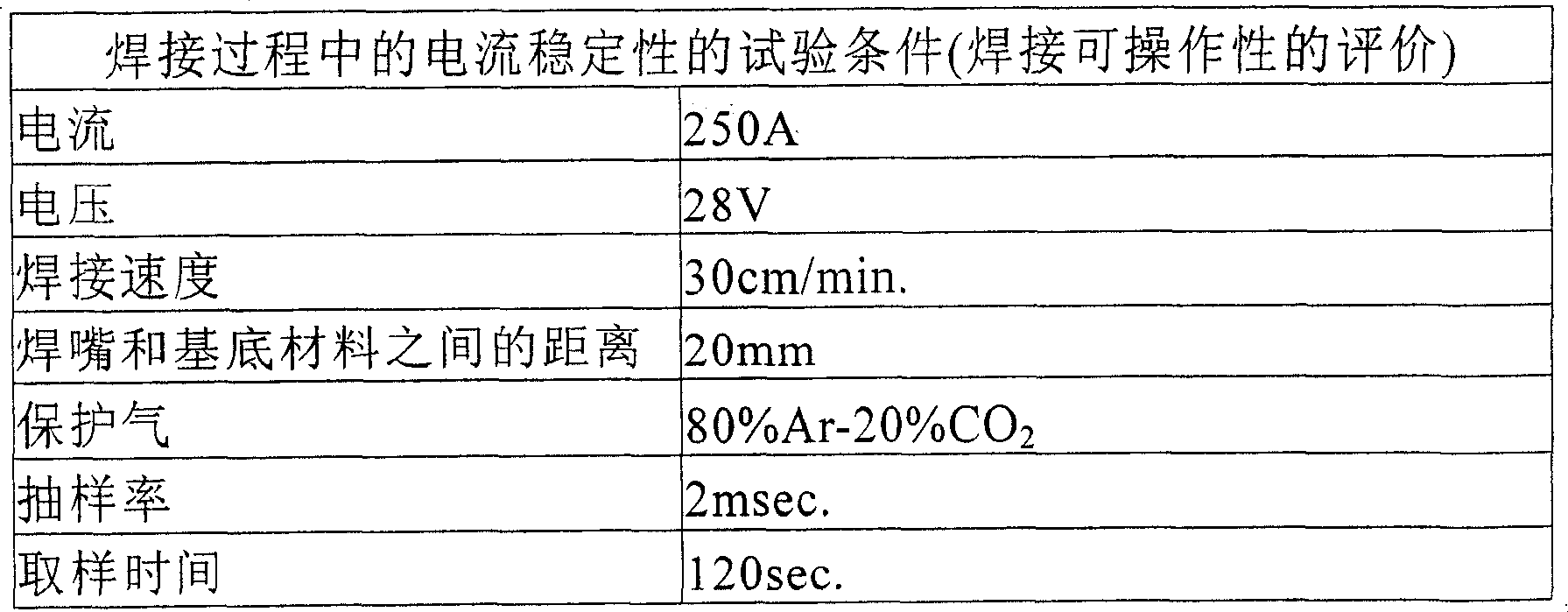

[0080] Examples of the powder-cored welding wire for gas shielded arc welding according to the present invention will be specifically explained below while comparing their characteristics with those of comparative examples.

[0081] A steel shell having a composition shown in Table 1 below was filled with 13% by mass of flux, and a cored wire for gas shielded arc welding (1.2 mm in diameter) having a composition shown in Tables 4 and 5 below was prepared.

[0082] [Table 1]

[0083] steel shell

No

C

mn

Si

P

S

Ni

Cr

Mo

margin

A

0.050

0.30

0.06

0.01

0.01

0.01

0.02

0.02

iron and inevitable

impurities

B

0.004

0.45

0.15

0.01

0.02

1.80

1.20

0.30

iron and inevitable

impurities

[0084] [Table 2]

[0085]

[0086] [table 3]

[0087]

[0088]

[0089]

[0090] The perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com