CaTiO3 structure La-Mn oxide/zinc oxide heterogeneous p-n junction and its making method

A technology of perovskite structure and manganese oxide, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of lack of large-scale production capacity and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

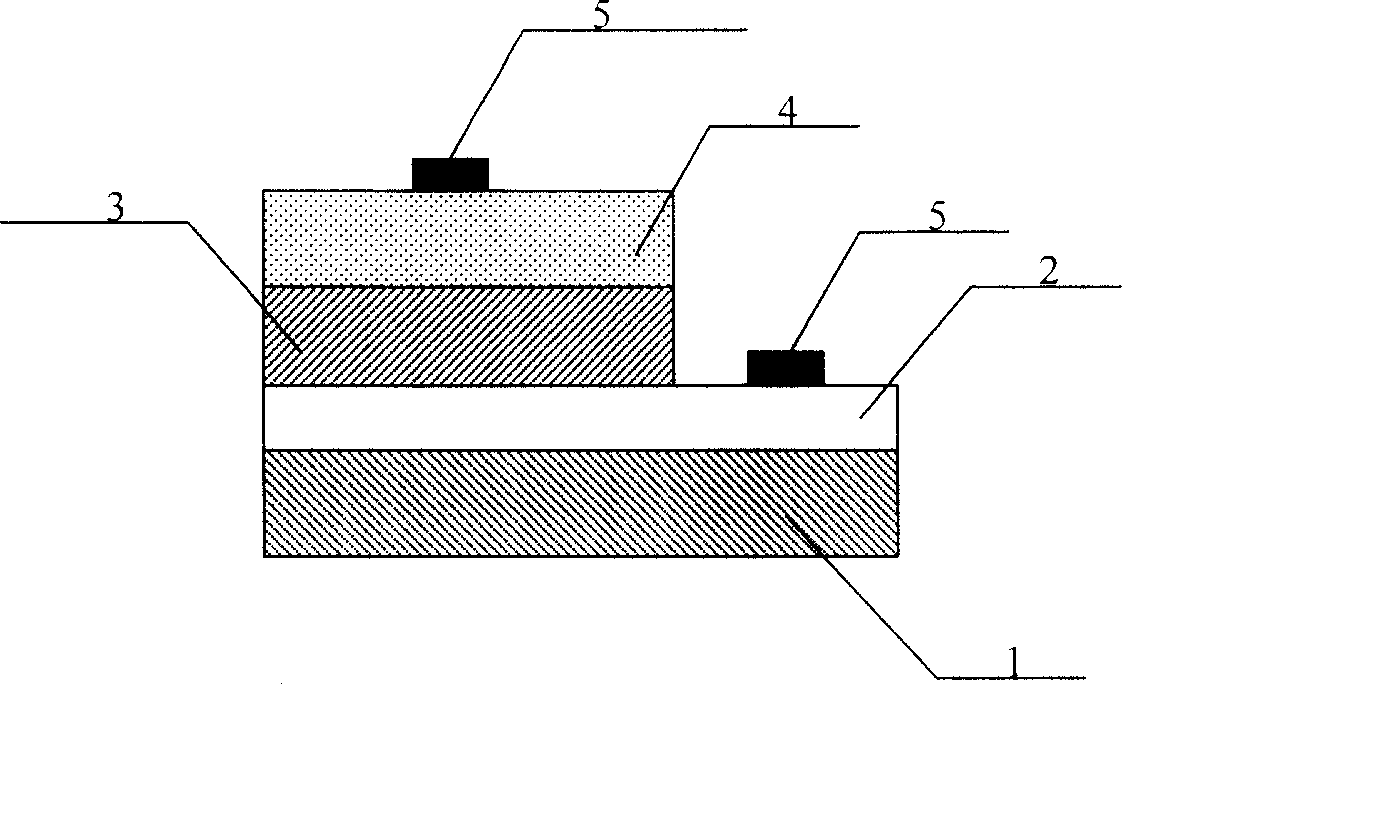

[0019] Using Si(100) single crystal substrate as the substrate, the perovskite structure Lanthanum manganese oxide / ZnO heterogeneous p-n junction was prepared by using ZnO and LSMO ceramic targets respectively. The specific process steps are:

[0020] 1. Prepare a 300nm-thick Pt bottom electrode on the substrate, and vacuum anneal at 500°C for 30min;

[0021] 2. Deposit a 300nm-thick ZnO film on the Pt lower electrode, and the process conditions are: substrate temperature 600°C, working pressure 0.1Pa, oxygen partial pressure 5%;

[0022] 3. After covering part of the ZnO film with a mask, deposit a 150nm LSMO film, the process conditions: substrate temperature 800°C, working pressure 0.5Pa, oxygen partial pressure 20%;

[0023] 4. Ag electrodes were deposited on the ZnO and LSMO thin films at a substrate temperature of 100 °C, respectively.

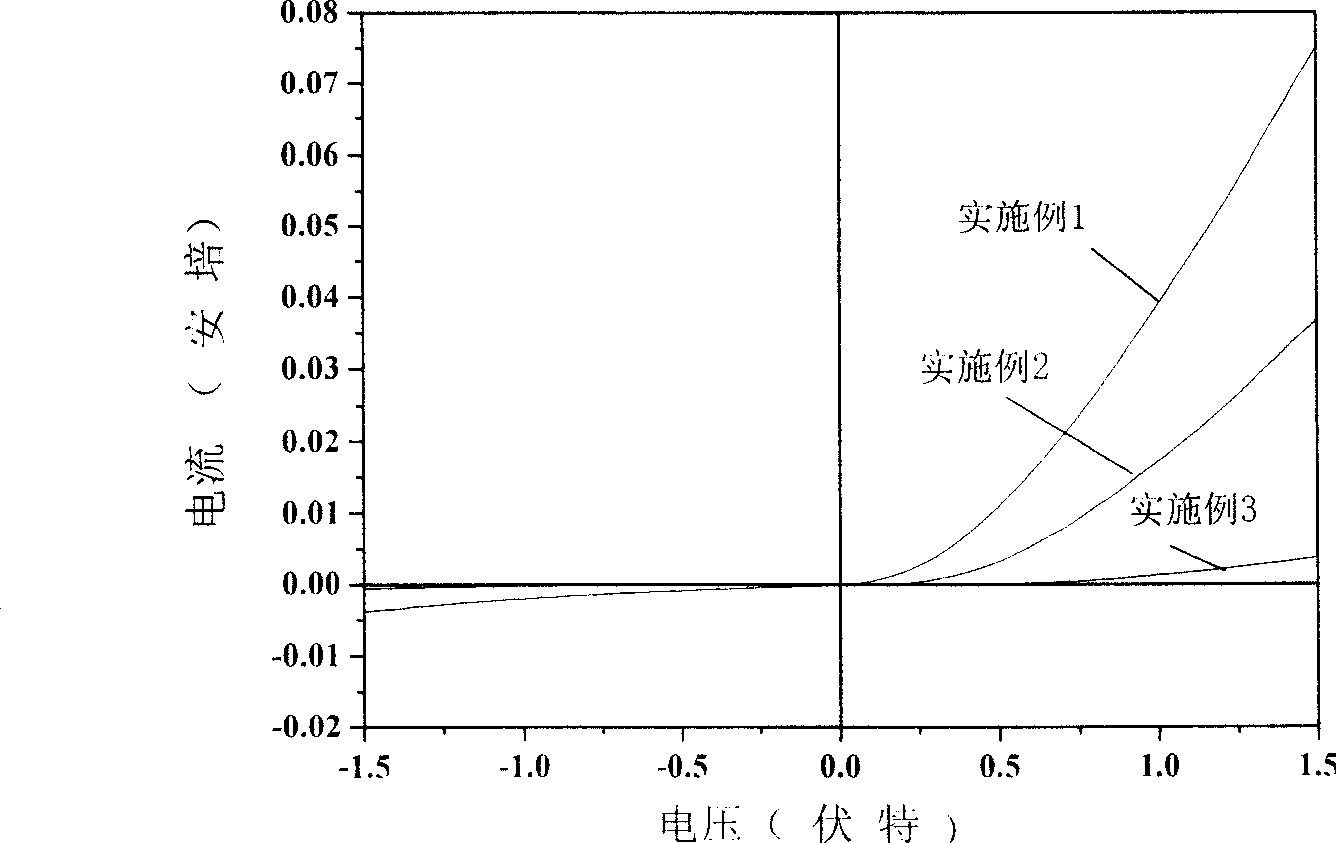

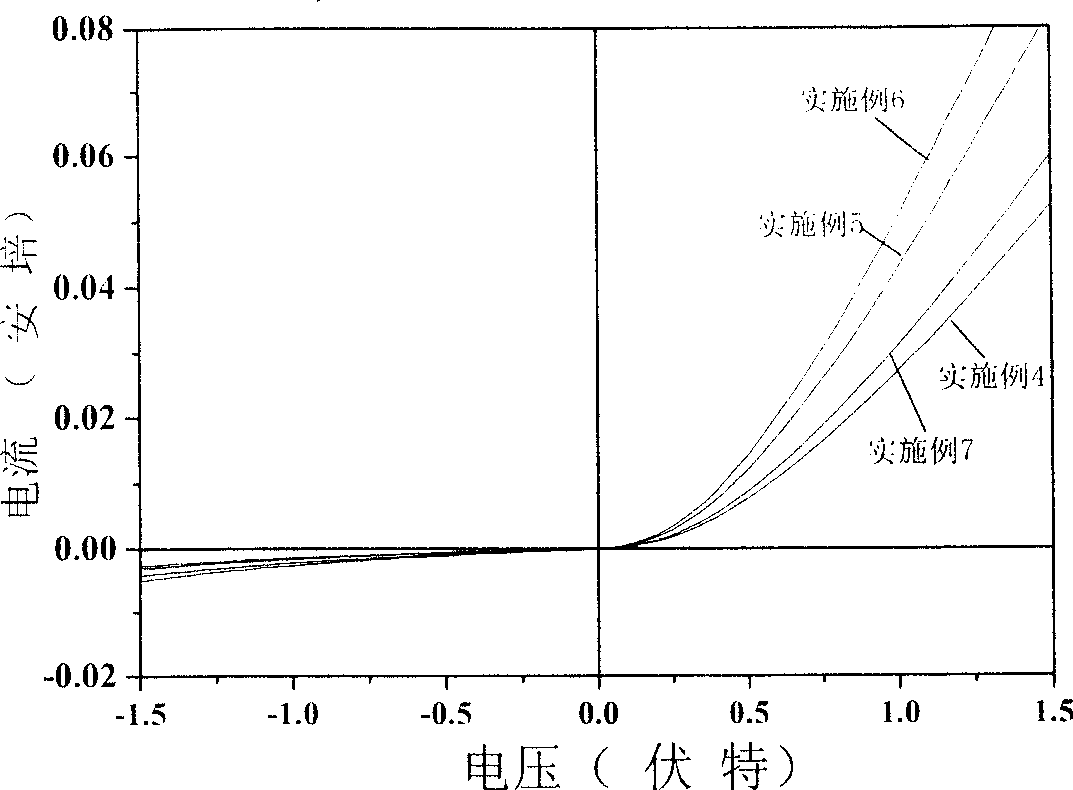

[0024] According to the above preparation conditions, different sputtering powers were used respectively (see Table 1).

[0025] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com