Nano intelligent temperature-controlled wall heater and its manufacturing method

A heater and nano technology, applied in the field of nano intelligent temperature control wall heater and its preparation, can solve the problems of high cost, high energy consumption, occupying space and the like, and achieve convenient use, low comprehensive cost, and high thermal conductivity uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Fabrication of a Nano Intelligent Temperature Control Wall Heater

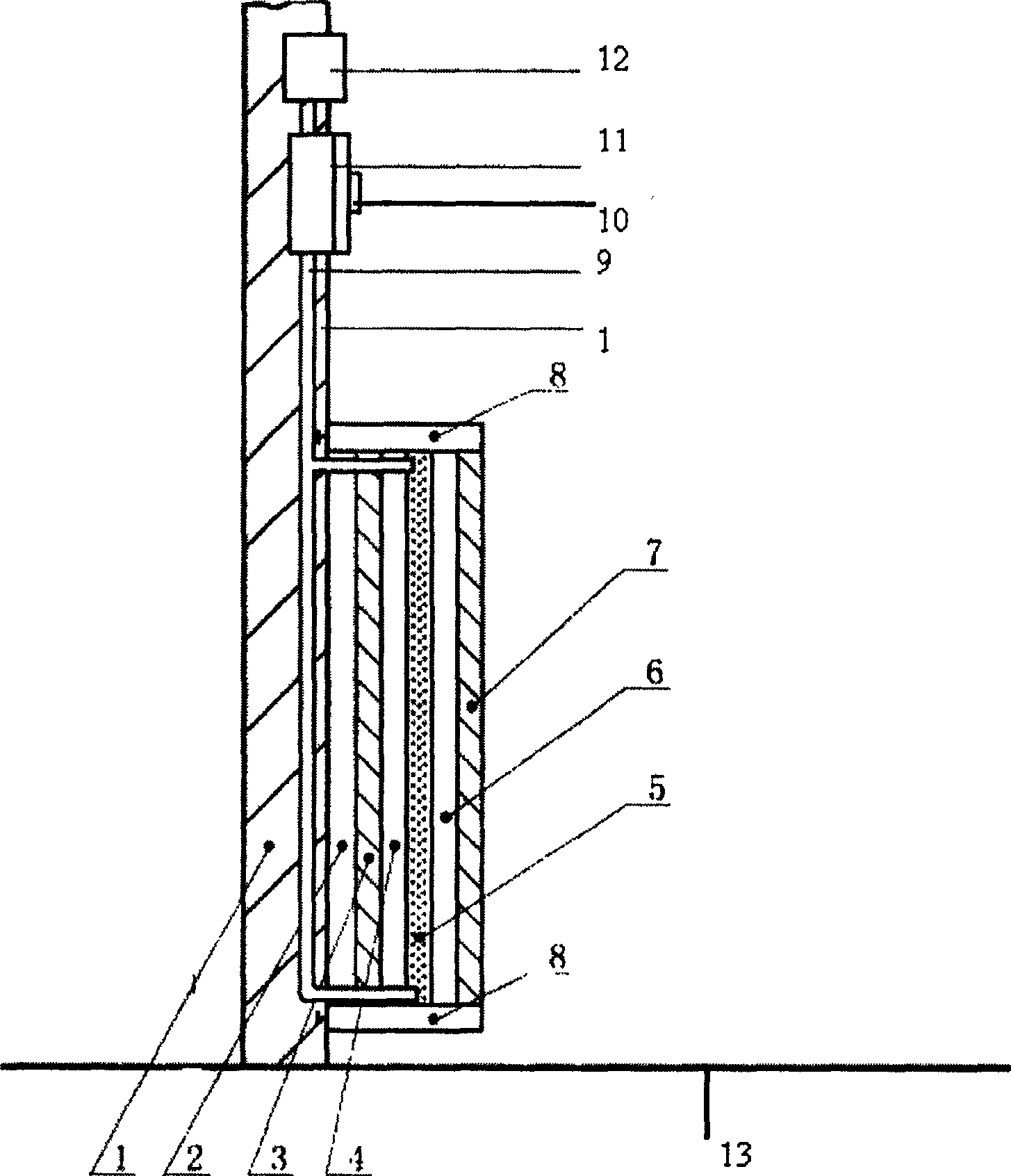

[0036] See figure 1

[0037] 1. Production of conductive silk fabrics

[0038] The conductive wire is silver-plated copper material with a diameter of 0.10mm and a tensile strength of 300N / mm 2 , The distribution of conductive filaments in the fabric (radial) 15 pieces / m, the yarn raw material is cotton yarn, the specification is 12s, the yarn is required to be free of impurities, foreign matter, moisture-proof, and woven by warp machine. Can not take off the edges, the weight per unit area is 500g / m 2 .

[0039] 2. Conductive silk fabrics are finished with "nano temperature memory material" coating

[0040] Take the method of padding coating: inspect and level the conductive silk fabric before coating, and remove foreign objects and thread impurities. At the same time, put the "nano temperature memory material" with a viscosity of 100mpa.s and a solid content of 10% in a stainless steel container and mix w...

Embodiment 2

[0047] Fabrication of a Nano Intelligent Temperature Control Wall Heater

[0048] See figure 1

[0049] 1. Conductive silk fabric production

[0050] The conductive wire is tin-plated copper material with a diameter of 0.75mm and a tensile strength of 1400N / mm 2 , The distribution of conductive filaments in the fabric (radial) 500 pieces / m, the yarn raw material is cotton and chemical fiber blended strands, the specification is 30s, and the strands are required to be free of impurities, foreign matter, moisture-free deterioration, and warp knitting. The wire cannot be detached, and the unit area weight is 100g / m 2 .

[0051] 2. Conductive silk fabrics are finished with "nano temperature memory material" coating

[0052] Take the method of padding coating: inspect and level the conductive silk fabric before coating, and remove foreign matter and thread impurities. At the same time, put the "nano temperature memory material" with a viscosity of 500mpa.s and a solid content of 70% in...

Embodiment 3

[0059] Fabrication of a Nano Intelligent Temperature Control Wall Heater

[0060] See figure 1

[0061] 1. Conductive silk fabric production

[0062] The conductive wire is silver-plated copper material with a diameter of 0.50mm and a tensile strength of 1000N / mm 2 , The distribution of conductive filaments in the fabric (radial) 300 pieces / m, the yarn material is cotton and chemical fiber blended yarn specification is 20s, the yarn is required to be free of impurities, foreign matter, moisture-free, and woven by warp machine , The wire cannot be detached, the unit area weight is 300g / m 2 .

[0063] 2. Conductive silk fabrics are finished with "nano temperature memory material" coating

[0064] Take the method of padding coating: inspect and level the conductive silk fabric before coating, and remove foreign matter and thread impurities. At the same time, put the "nano temperature memory material" with a viscosity of 300mpa.s and a solid content of 50% in a stainless steel contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com