Potato starch shrimp cracker and processing method thereof

A technology of potato starch and shrimp chips, which is applied in the application, food preparation, food science and other directions, can solve the problems of reducing the utilization rate of raw materials, environmental pollution, etc., and achieve the effects of enriching product types, reducing environmental pollution, and easy to expand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

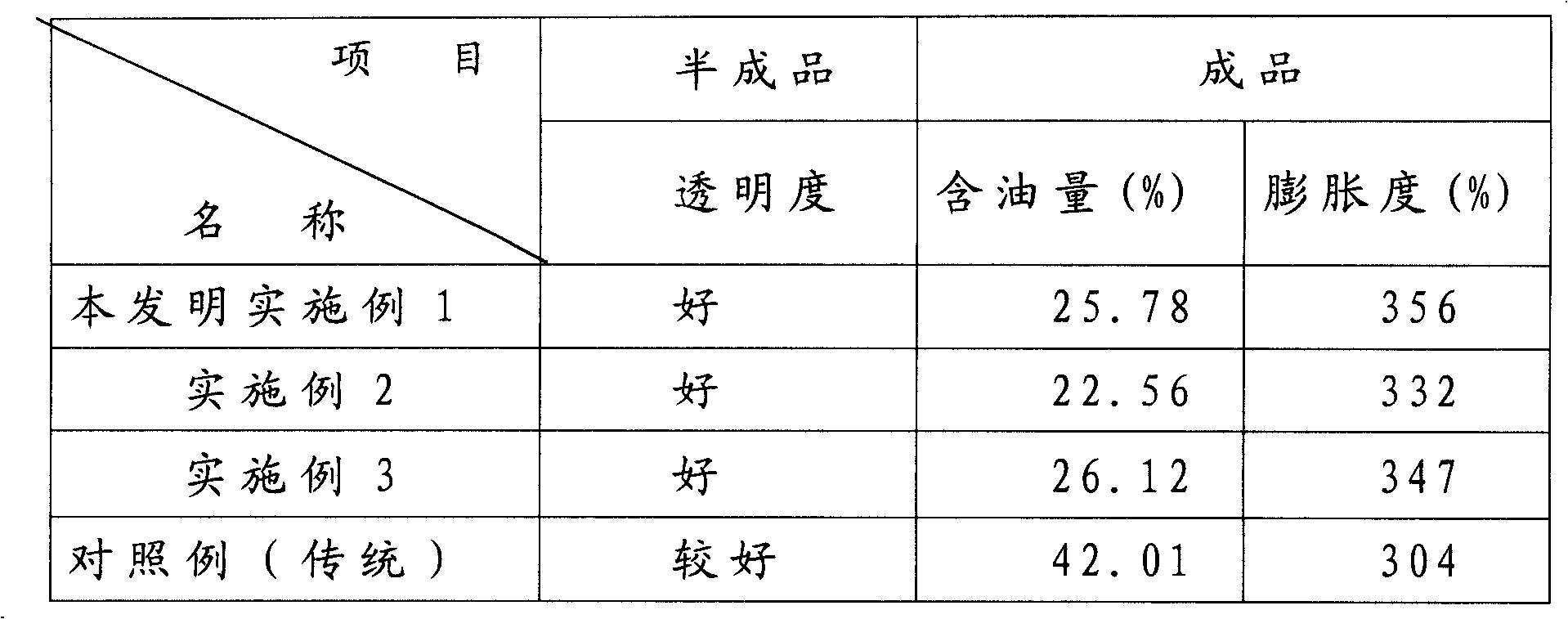

Embodiment 1

[0023] Embodiment 1, get extracted potato starch 840g. Boil 840g of water, add seasoning at the same time, in the seasoning, salt 12g, sucrose 50g, monosodium glutamate 12g, take 200g of potato starch and 280g of water to make a slurry, slowly pour into the stirring water until the paste is transparent, Keep the gelatinization temperature at 70°C; add the above-mentioned gelatinized hot starch slurry into a mixture consisting of 640g of remaining starch, 30g of shrimp, 5g of baking soda, 5g of alum, 3g of sodium carboxymethyl cellulose, and 4g of sucrose ester and stir , make a uniform dough, take out the dough, make shrimp sticks of corresponding specifications according to the requirements, cook them at 1.2 atmospheres for 35 minutes, cool the shrimp sticks naturally, and cool them at 2°C for 7 hours. The strips are cut into slices with a thickness of 1.5-2.0mm and dried at a temperature of 40°C for 6 hours. After drying, the water is 90g, and then packaged into semi-finishe...

Embodiment 2

[0024] Embodiment 2, get extracted potato starch 1500g. Boil 1500g of water, and add seasoning at the same time, 16g of salt, 75g of sucrose, and 17g of monosodium glutamate in the seasoning, take 300g of potato starch and 500g of water to make a slurry, slowly pour it into the stirring water until the paste is transparent, Keep the gelatinization temperature at 90°C; add the gelatinized hot starch slurry to the mixture consisting of the remaining starch 1200g, shrimp 50g, baking soda 8g, alum 7.5g, sodium alginate 7g, and monoglyceride 5g and stir. Make uniform dough, take out the dough, make shrimp sticks of corresponding specifications according to requirements, cook for 40 minutes at 1.2 atmospheres, cool the shrimp sticks naturally, and cool them at 4°C for 8 hours. Cut into thin slices with a thickness of 1.5-2.0 mm and then dry. The drying temperature is 42°C and the drying time is 6.2 hours. The moisture content of dried shrimp chips is 160g; then packaged into semi-fi...

Embodiment 3

[0025] Embodiment 3, get extracted potato starch 1200g. Boil 1200g of water, and add seasoning at the same time, salt 16g, sucrose 65g, monosodium glutamate 17g in the seasoning, take 280g of potato starch and 400g of water to make a slurry, slowly pour into the stirring water until the paste is transparent, Keep the gelatinization temperature at 80°C; add the gelatinized hot starch slurry to the mixture consisting of the remaining starch 920g, shrimp 50g, baking soda 7.2g, alum 7.2g, xanthan gum 4g, polyglycerol fatty acid ester 5g Stir in medium to make a uniform dough, take out the dough, make shrimp sticks of corresponding specifications according to requirements, cook at 1.2 atmospheres for 40 minutes, cool the shrimp naturally at 3°C for 7.5 hours, Shrimp crackers are cut into thin slices with a thickness of 1.5-2.0 mm and dried at a temperature of 42°C for 6 hours. After drying, the water content in the shrimp crackers is 130g; then packaged into semi-finished shrimp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com