Arsenic comprising groundwater processing method

A treatment method and technology for groundwater, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as the inability to ensure the removal of other pollutants, the inability to ensure the treatment capacity, and the complex operation and management. , to achieve long-term stability of arsenic removal effect, excellent arsenic removal efficiency and broad-spectrum adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example, the raw water contains 100 μg / L As(III) and does not contain Fe(II) and Mn(II).

[0031] Pump the composite high-efficiency oxidation flocculant into the raw water under the condition of sufficient stirring, and the composite high-efficiency oxidation flocculant is composed of 0.17mg / L potassium permanganate and 1.02mg / L ferric chloride.

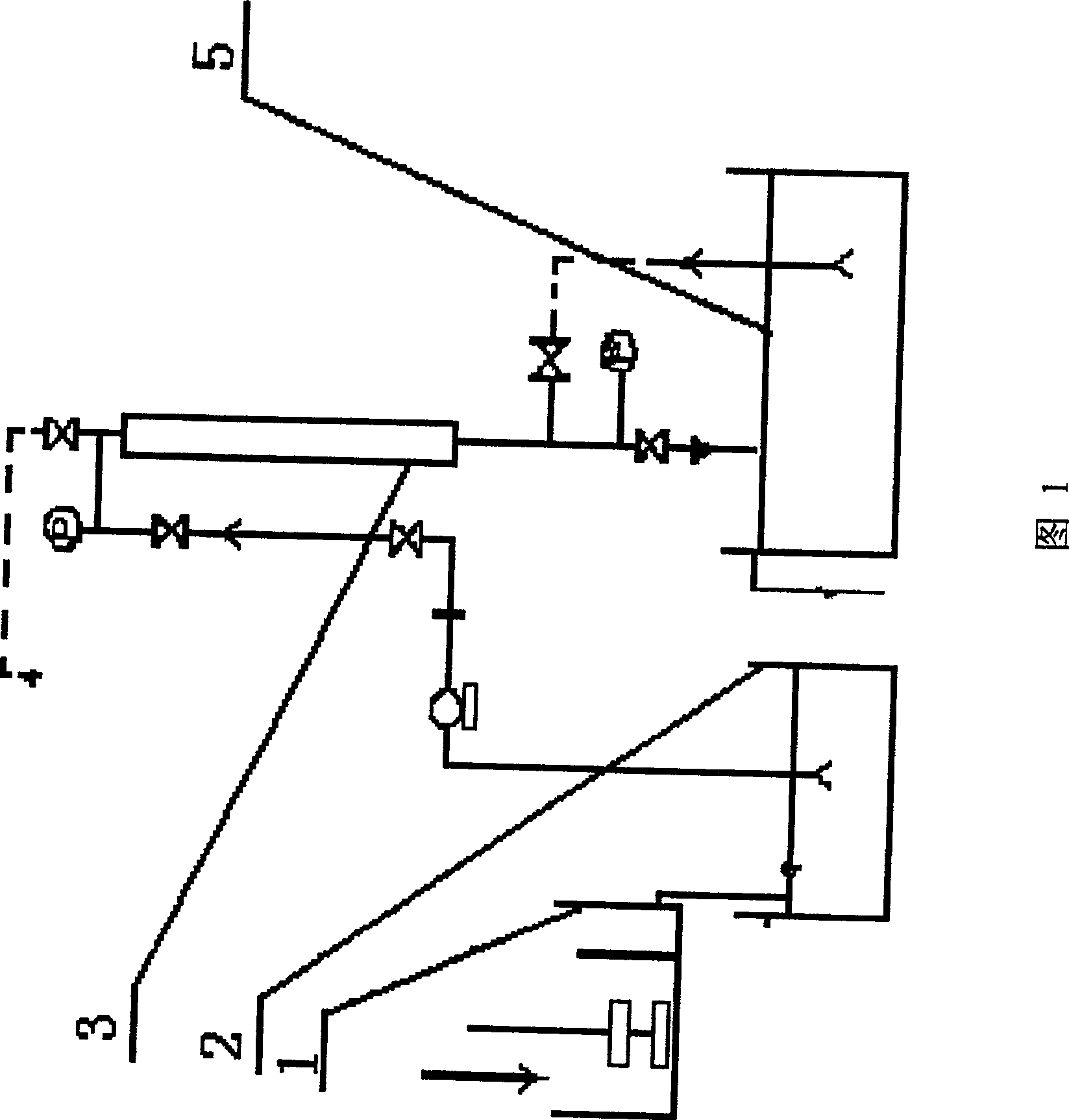

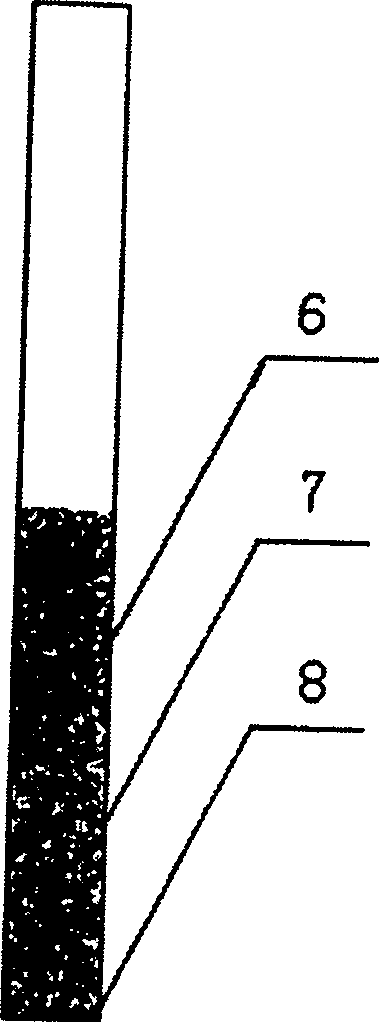

[0032] Figure 1, figure 2 As shown, in the mixing reactor 1, under the condition of sufficient stirring, the composite high-efficiency oxidation flocculant is pumped into the arsenic-containing groundwater for mixing, and the residence time of the arsenic-containing groundwater is 30 seconds; in the flocculation reactor 2, flocculation, adsorption, Co-sedimentation and other physical and chemical processes, the residence time of arsenic-containing groundwater is 15 minutes. Afterwards, enter the composite double-layer filter column 3 to filter, wherein the composite double-layer filter column 3 upper layer is a granu...

Embodiment 2

[0034] In this example, the raw water contains 100 μg / L As(III) and does not contain Fe(II) and Mn(II).

[0035] Pump the composite high-efficiency oxidation flocculant into the raw water under the condition of sufficient stirring, and the composite high-efficiency oxidation flocculant is composed of 0.17mg / L potassium permanganate and 1.02mg / L ferric chloride.

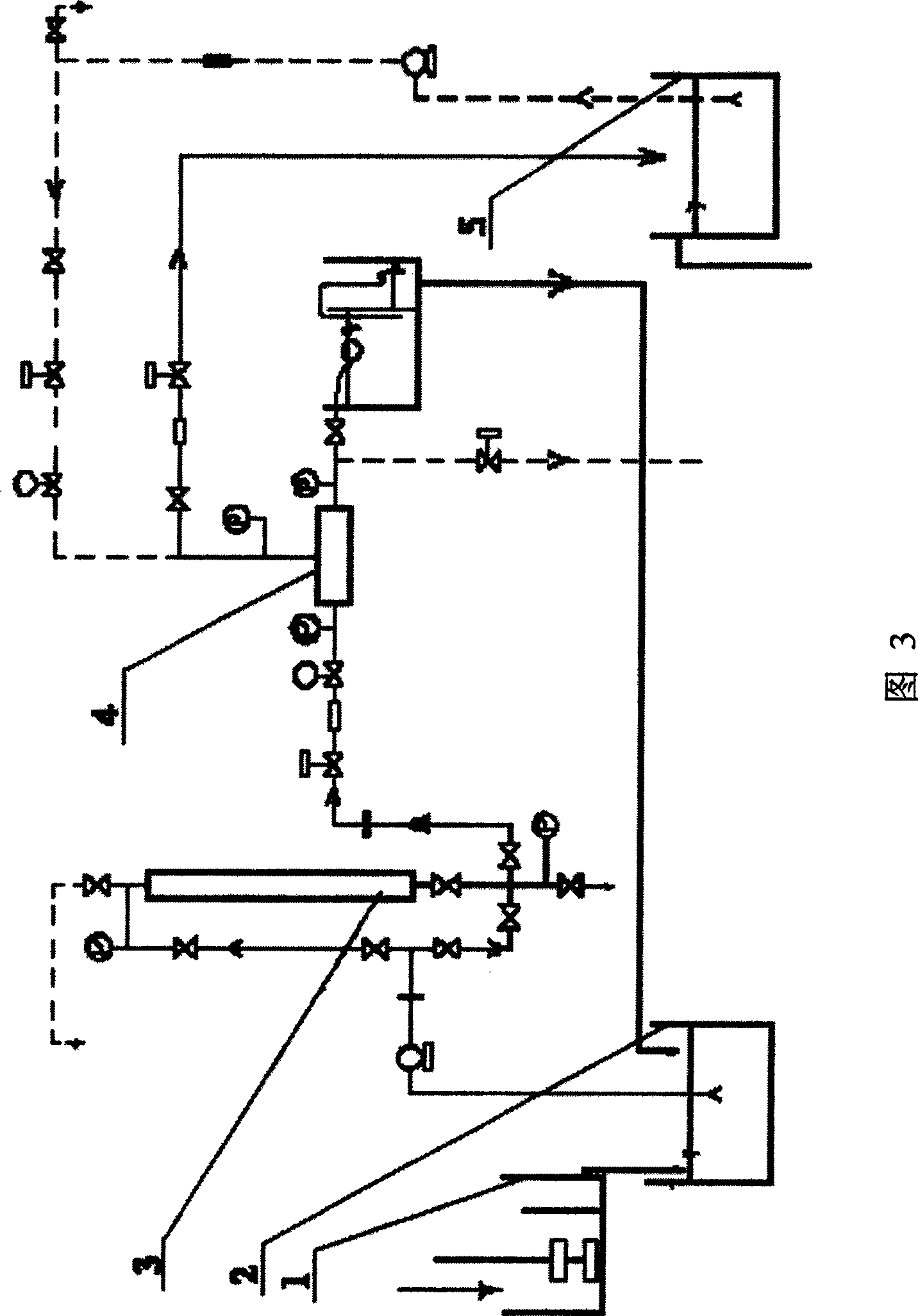

[0036] As shown in Figure 3, figure 2 As shown, in the mixing reactor 1, under the condition of sufficient stirring, the composite high-efficiency oxidation flocculant is pumped into the arsenic-containing groundwater for mixing, and the residence time of the arsenic-containing groundwater is 30 seconds; in the flocculation reactor 2, flocculation, adsorption, Co-sedimentation and other physical and chemical processes, the residence time of arsenic-containing groundwater is 15 minutes. Afterwards, enter the composite double-layer filter column 3 to filter, wherein the composite double-layer filter column 3 upper laye...

Embodiment 3~31

[0038] Other conditions remain unchanged, according to the main water quality indicators of raw water, determine the composition of the composite high-efficiency oxidation flocculant, and its treatment effect is shown in Table 2 on the next page.

[0039] Table 2 Treatment effect of the present invention

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com